Yep. Solder blobs weren’t the right approach.

Lately, I’ve also soldered a tiny copper wire to both sides of the driver, flattened it with a tap (it’s soft already from heating) then squeezed that into place.

Same idea as filling the vias — make the ground ring around the driver electrically contact the pill ….

No problem. You is not first who is asking about them, and 10pcs is enough quantity to make small batch.

I understand that everyone wants solid plane.

SK98 is much less popular than SK68. Also they are not so cheap and closer to better 18650 zoomies in price

I enjoy them myself. Once they almost burned my jeans pockets internal (with trustfire 14500 cells). But they are not as good in heat spreading as sipik with solid pill.

Also I think that we can move pcb shelf a little to have such zoom out and zoom in beams as you want to.

I think there is no need on driver soldering in such projects. You can solder driver to copper pill using torch but it is not safety.

To other ways:

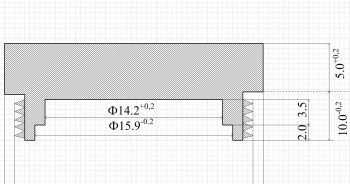

- Press fit. Driver place is 0.2mm smaller than driver OD, you need to file driver until it enters in its place by half around and then press it inside

- Pill rim press. In fact with 15-16mm driver place rim is thin and you can simply bend it inside to hold driver.

SK68 $2 chinise clone single led solid shelf copper pill interesting list:

- leroycp - 6pcs

- hank - 10-12pcs(?)

- pscal - 2pcs

hm, I’ll go with “whatever” in the end, but curious.

On all the ones I have the side groove on the large diameter is used to hold either a rubber ring or a metal spring — that’s what gives enough friction to keep the sliding part from slipping back and forth, just enough contact (with a little lubrication) to make the focus change smoothly and stay where it’s set.

With that setup there’s probably some slop in the inner diameter of the focusing sliding part, filled by the ring/spring.

How would you focus the light if it’s just two cylinders one inside the other — thick grease? But that would goop out onto your hand, when the slider was full forward (narrow), I’d think?

If you mean the side groove just above the threads, I don’t see any use for that one.

Yes, my mistake, I used drawing of triple with fixed position and forgot about head fixing.

I will check how does it works with 1 o-ring exept of two in stock.

Looks much better than clone pills.

Yes, will copy one groove for 20x1.5 o-ring.

What about pcb shelf position?

I hope everyone will agree to get rid of side grooves and other unuseful things.

This design have about 5mm upper shelf than stock. Please check your lights, if you dont like this idea we can move it lower back.

I can’t speak for the ’68 as I don’t have one, but at least for the ’98, the piece with the front lens slides around the pill from the back end, and has an inner “ledge” to keep the pill from pushing through the other end. The pill then screws into the battery-tube.

This inner ledge keeps the slider+lens from being pulled off the tube completely. I think you’d need to keep the outer threads on the pill.

(Someone correct me if I’m wrong.)

On the X-section drawing, also, you do want a depression cut out for the single emitter board to sit in.

(That’s been hard for a lot of manufacturers to get right, they cut the bottom cupped or domed, and too thin, if they have a ‘solid’ pill at all)

16mm boards should fit into that depression, flat back against the flat part of the pill, with a little bit of play but less than a millimeter or so around the edge, since the depression cut won’t have perfect right angles between side and base)

(A 10mm square Luxeon Rebel board will also fit nicely into that cutout — diagonal measure of that board is (square root of 200) = 14.14mm again leaving a tiny bit of play at the corners.)

We can probably drill our own holes in these things, or I can anyhow.

You don’t want the pill to have the completely flat top surface that people use for triples.

the piece with the front lens slides around the pill from the back end, and has an inner “ledge” to keep the pill from pushing through the other end. The pill then screws into the battery-tube

That’s true for the SK68 as well. So yes, that puts a lower limit on the diameter of the pill.

The metal of the pill hitting that little ledge inside the slider is what keeps people from pulling the slider off the flashlight.

But you’re not making the sliders — just have to make sure the pill fits into the wider diameter (front end) of the slider and stops at the ledge inside the slider.

You can’t remove the slider until you unscrew the pill from the battery tube

(both the pill and the slider can rotate)

Then you can remove the slider with the pill still inside it, loose

Then you can push from the driver side to push the pill out the front (threaded) end of the slider.

If you push from the emitter side the pill slides back til it hits the ledge inside the slider and stops.

Sometimes it is hard to understand you guys.

Drawing that I have shown have external threads.

Lower part of bezel, that slides together with the lens, is hold by pill`s largest diameter (it should be about 21.0mm) (there is step inside lower part of bezel).

PCB depression (I thought this is thermin from geografics), o-ring grooves, holes…going to be too expensive as I think.

Pill with flat surface is good for those who like:

- different pcbs (first time I have made some pill to fit 16mm noctigon and realizes that sinkpad requires 16.5mm place), even 20-21mm

- polish this surface

- use extra copper plates to make precision focus adjustment

Anyway I still havent received any info about this pcb shelf position. Im sure here lots of users that have tested SK68 with different leds.

Yes hank your description of slide boards are right.

> hard to understand you guys.

Not your fault, words are hard to find to describe this stuff.

> step inside lower part of bezel.

“bezel” meaning the long tube that slides, right? That step sounds like what I see and how it works to stop the pill from sliding out the back end of that tube.

(I usually think bezel means the very frontmost part that screws on to hold the lens, but I understand what you mean there I think)

> PCB shelf

If the LED position is any closer than the stock distance to the lens at full extension, then you won’t get a focused image of the LED at full narrow zoom.

Most people like to see that.

(I don’t mind a defocused round spot with fuzzy edges myself, I get that when I stuff a disk of copper or aluminum onto the stock shelf, lifting a replacement LED up slightly)

(or for that matter when I use a LED that comes on a 1.5mm board — I think the stock thin aluminum board is at most 1mm thick, maybe less)

> too expensive

That’s what I was afraid might be the case, to get the cutout for the 16mm board, etc.

I think the single O-ring groove is necessary — without a groove for an O-ring or wire spring, the slider/focus will just flop around loosely if there’s a bit of a gap between battery tube and sliding tube. And I’d guess the dimensions on the clones are fairly loose so a pill needs that one O-ring to fill that gap.

I know people have replaced with thicker or thinner O-rings when the slider was too tight or too loose, or added a bit of lubrication to it.

For a flat top pill, I guess we can drill and tap holes for screws to hold the emitter in place — which would be better than the press-fit washer to hold it down.

Or solder a copper board LED to the pill, if there’s a way to keep it centered while soldering. I have got to learn that sometime (grin)

And centering the LED isn’t all that important for lens-type zoomies anyhow, as long as it’s fairly close to center, it looks fine.

Wait on someone smarter than me to comment, this is a good start.

I can’t speak to the measurements. Looks good to me though.

PS — for this kind of gift-giving, I like the “#3 zoom” better than the SK68.

Fewer sharp corners, more pocket-friendly. Also takes the 15mm SK68 driver and same emitter

And when a millimeter is filed off the slider, bringing the lens right down to the LED, they give a generous flood, while the narrow beam isn’t affected.

I won one of those in a Gearabest giveaway awhile back. I put a 14500 battery in it and it is a neat little light. Can’t beat it for the $$.

Bob

Hello!

Is this stuff what I think it is?: DIY 20.8mm(D) x 16mm(H) Aluminium Driver Pillar Set for LED Flashlights

Compared to my clones, the shelf seems thinner (located a bit upwards) and the threading is longer. I have a couple of 'em and they use a different pill threading :FACEPALM: ; the bodies also differ a bit in lenght. ![]()

Cheers ^:)

Yes, they should fit. If they exist, I suppose nobody will be interested in same design copper pills for $13-15.

Not sure how much of the cost is the material/effort of cutting copper.

Have you made any pills with the back plane out of aluminum?

That would avoid the metal-on-metal spalling/corrosion

For 1-2-amp power the little zoom lights should be ok for heat.

I tried asking at that page Barkuti points to whether anyone knows what those fit (or don’t fit)

I want someone to invent a little magic box into which I can put a threaded item, and have it read out the definition of the thread so it can be matched!

But I suspect a lot of cheap flashlights don’t even use a standard thread specification (sigh)

For cheap hosts like the SK68, it might be preferable for a host to be provided with the pill, because of how many inconsistencies there are out there.

Not sure how much of the cost is the material/effort of cutting copper.

Have you made any pills with the back plane out of aluminum?

That would avoid the metal-on-metal spalling/corrosion

For 1-2-amp power the little zoom lights should be ok for heat.I tried asking at that page Barkuti points to whether anyone knows what those fit (or don’t fit)

I want someone to invent a little magic box into which I can put a threaded item, and have it read out the definition of the thread so it can be matched!

But I suspect a lot of cheap flashlights don’t even use a standard thread specification (sigh)

Material cost of such parts is less than 10% from machining cost.

I dont think there is any need in any aluminium pills.

Those pills should fit well.

As I can say most cheap lights have metric threads, while more expensive one mostly have some exotic shape threads.

> Yes, they should fit. If they exist

DX apparently has sold out of them.

Yes, they should fit. If they exist, I suppose nobody will be interested in same design copper pills for $13-15.

Mmm, not so sure. My cheap hosts' hollow pills measure 14mm, which is 2mm short of that (now out of stock) pill at Kaidomain. ![]()

For cheap hosts like the SK68, it might be preferable for a host to be provided with the pill, because of how many inconsistencies there are out there.

Agree. I think it would make much more sense to get on machining custom, well designed hosts.

Yesterday I stacked a barrage of sense resistors on a 3-mode SK68 clone driver in order to seriously improve the driving current with Ni-MHs, and added another boost cap. Result: neither visual (tailcap sprint bypassed) nor multimeter tailcap amps discernible. ![]()

Particularly I thought that, since the crappy boost driver had not li-ion low voltage protection/shutdown, and not wanting to make any sort of exotic mod to put a 14500 protection PCB inside the pill, I'd go the Ni-MH route. But alas, driver replacement too? The whole idea is stupid I now think, a good li-ion 14500 is an under-developed crap too, and fitting one of those new 16650s would require a custom-crafted tube extension. The whole sheesh is an unbeliebable pile of… sheesh; a good pilled Ultrafire XM-L2 SK98 plus an XP-G3 is cheaper and will easily blow away any ignominious frankenstein improvement mods over SK68s, it's a failure by design. ![]()

Sorry for the rant. ![]()

Cheers fellows ^:)

You rant for me too.

the Ni-MH route. But alas, driver replacement too?

Alas. MtnElectronics had one decent 1xAA boost driver, now down to none for sale on the site.

RMM has said that he’s had thoughts about someday making and selling a decent 1xAA/2xAA driver.

May the day come.