Very Nice!

Looking really good there!

Super nice clean work Steve. All those little parts are the pits to turn out aren’t they. They get tiresome after the first three or so.

Really nice!!! TL

It could of been TL but I’ve had a break from it for awhile and I do love why these are getting made.

Thanks for the comments guys. Any suggestions are more than welcome.

You’re a good egg Steve. I love why you are making them too. Suggestions…. well, when parts look like that, suggestions are tough! That is as clean of work as anyone on earth could ever ask for!! ![]() :+1:

:+1: ![]() TL

TL

Update 12.10.16.

The threads for the tailcap on the battery tube were machined next. The OD of the thread is 46.5mm.

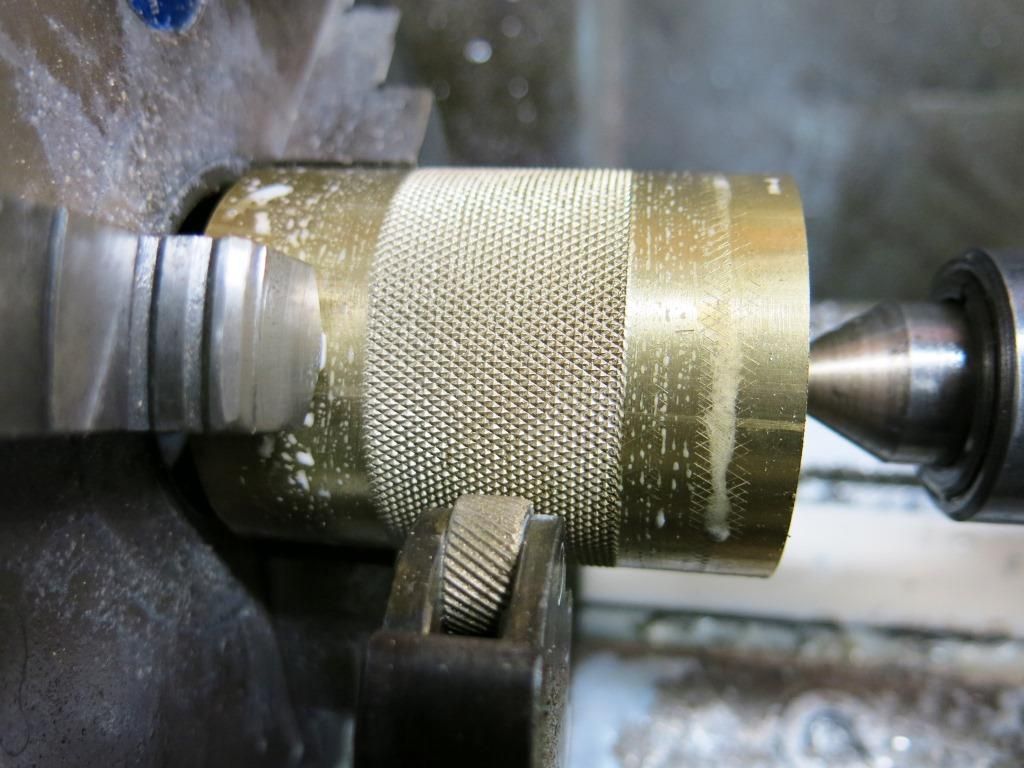

This picture is turning the OD of the battery tube down to size and machining the oring groove.

The thread in its raw form. Pitch is my usual 1mm.

And the finished threads.

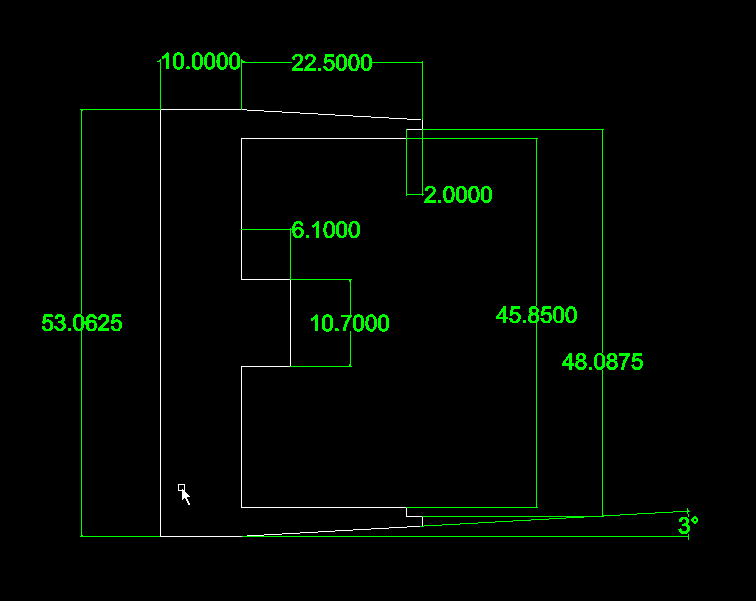

Knowing the thread on the battery tube, I could now draw up the tailcap. The spigot in the centre is what the copper negative plate will rotate on. It will be threaded 6mm and the plate held captive with a taper head cap screw.

The two tailcaps will be machined from one piece. I’m not sure of the outside look as yet but knurling had to be in the picture somewhere.

The inside was machined to the depth of the spigot here.

The tailcap spigots were then machined in the mill. The rotary table is 90 revolutions of the handle to one turn of the table.

2160 turns later we have two spigots roughed out. The tailcaps will internally be finish machined in the lathe next.

Nice Steve!!! Most of yesterday I was covered in chips! But I still super enjoy looking at your machining images. What a light this is going to be. The quality of work is just stunning!

More! More!!! :+1: TL

I have very little to add as I have none of the experience of most of those commenting here. This may come across as ignorant, but when looking at the pics of the dowel’s and battery tubes the first thing that came to mind was a revolver chamber and bullets. ![]()

PS. Beautiful work.

The first time I looked at those images, that was my thought too…. looks like my Ruger 41 Mag!!! ![]() TL

TL

:+1: ![]()

:laughing: I cant say that thought ever crossed my mind. May I ask TL what sort of light the chips were coming from? Good to see you back at it. ![]()

I have seen the machined parts and would like to dub this light “The Gatling”.

This update I’ve started the machine work on the head of the light. As this light will get hot in operation I thought I’d go one step further with this idea I used on the XMTG shocker build.

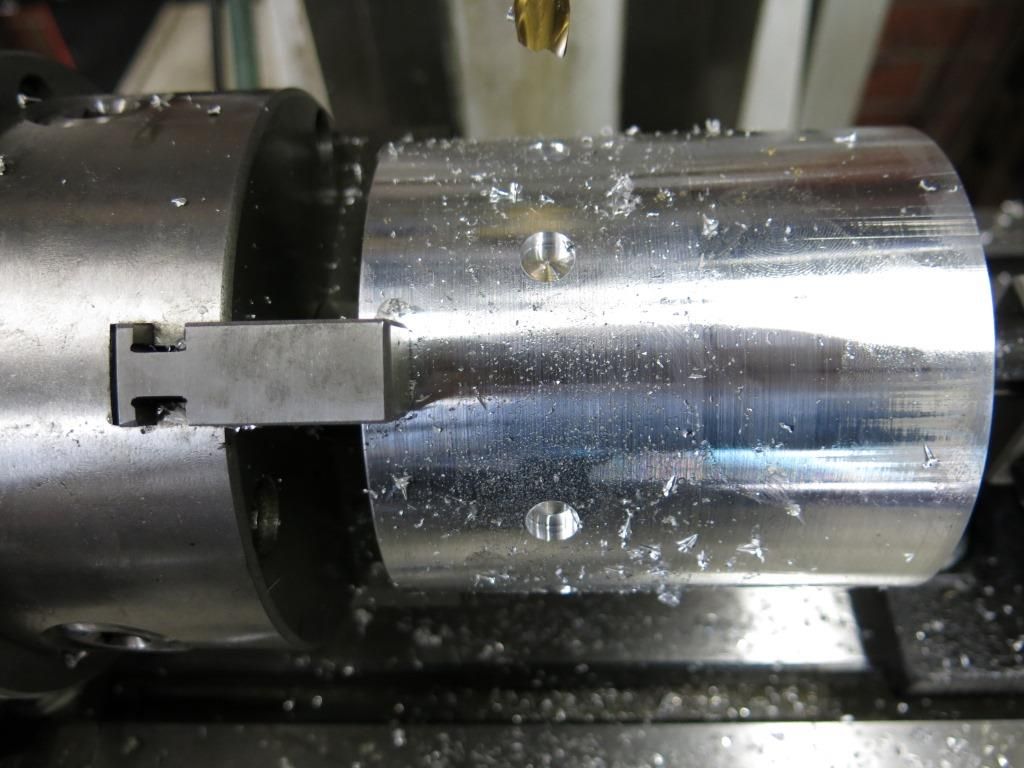

The driver pocket was machined first in the 100mm diameter x 108mm long aluminium round bar. This head differs from a normal head as the battery tube will be bolted to the head as per OL’s way of doing things and not threaded as per normal.

The head was then transferred to the mill where four 3/8’’ holes were drilled through the shelf under the led which is 17mm thick. Here is the marking out for the holes.

The through holes were then drilled.

3/8’’ copper bar was then cut to 100mm in length.

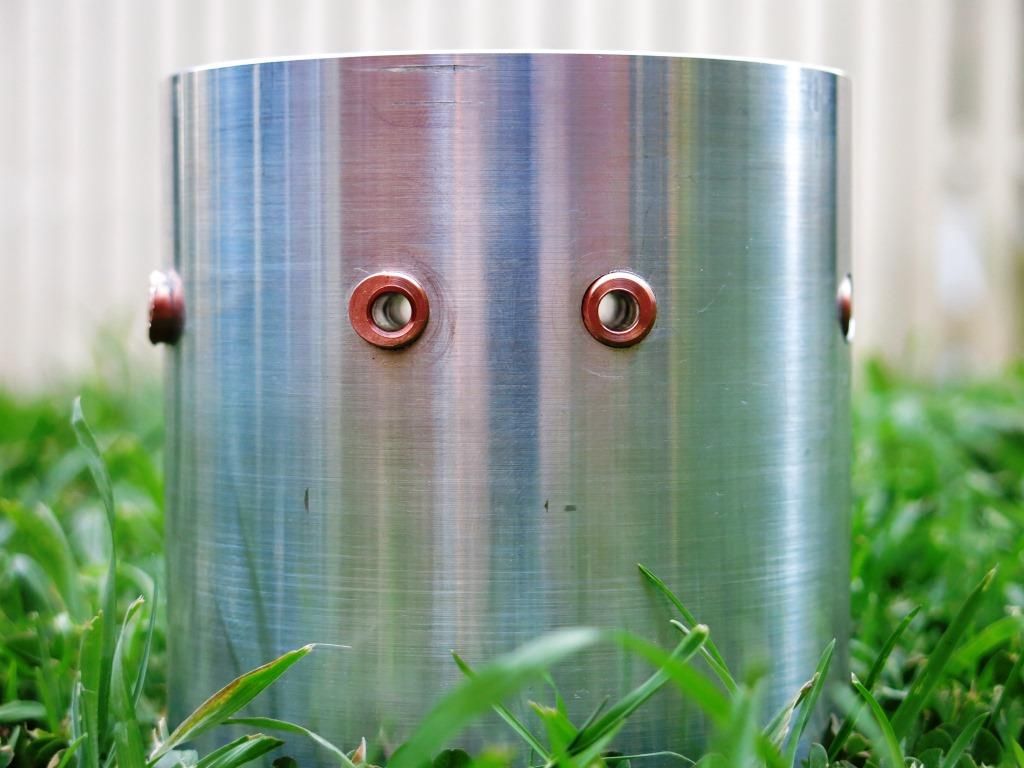

These were then glued and hammered into the head of the light.

The drill used to drill through the 3/8’’ copper bar was 3/16’’.

One down one to go for the heat sinks.

Do the rods intersect?

Yes. I drilled all the holes and then inserted two rods, drilled through them and then inserted the last two rods.

superb work.

Im drooling

Thanks nic. With all the comments on what bits of the light looks like a mate suggested that the head looked like Ned Kelly’s helmet. The other head is now at the same stage as the first one gone away for a bit of r and r so will get back into it when l get home.

Just beautiful!!! That is creative from the start. Danged nice machining too!!

TL

I really just can hardly keep myself from flying down there, to see the light finished! Well, other than money, health, fear of flying, the wrong tide, the moon phase... you get the drift.![]()

I really am very excited to see the glam shots and beam shots of this beauty when it is done!! Your work is impressive, to say the least.

:laughing: I cant say that thought ever crossed my mind. May I ask TL what sort of light the chips were coming from? Good to see you back at it.

Sorry Steve, I was re-reading this post…. enjoying your great work AGAIN…. and noticed the question. That day I was working on a 26650 light sized for an optic. It was a “Shorty”. ![]() Just over 5” long when finished. It was really a prototype, we will put these in production mid November.

Just over 5” long when finished. It was really a prototype, we will put these in production mid November.

I sure enjoy your images and work. !! TL