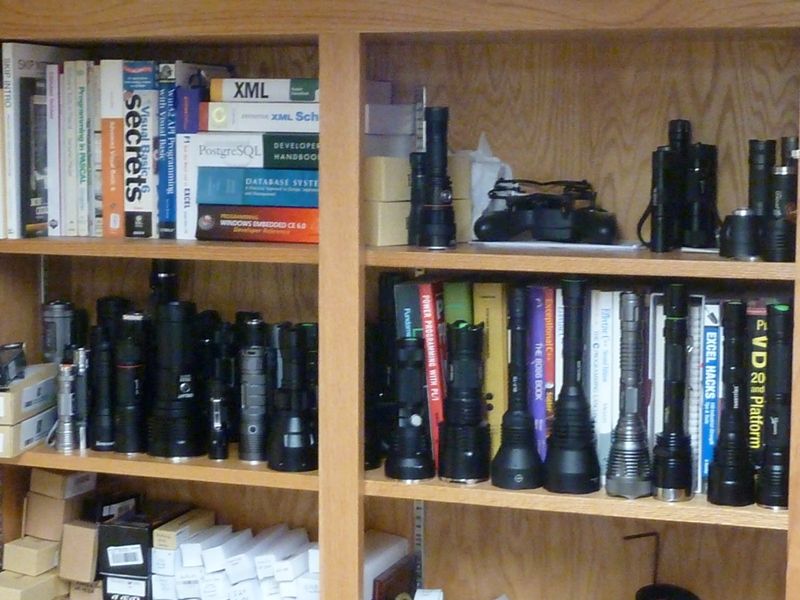

Cheers bro, I’m kind of a confused person myself. Looking at my harem of lights I wonder…. Am I sane?

Yes indeed, I counted what lights I have in plain site, phone rang and last I recall I was somewhere in the high 80’s, I could probably times that by three and come out short, it is insane.

It get even stranger when your going to go out in the evening and can’t decide which light to take with you…

Sane?

Hehe. I feel home here.

Impressive.

What’s to the right of the M24 ?

We could have a name that light contest, wow, where is the brown box room, nobody throws their boxes away, do they?

2X.?

The MaxToch 2X I believe...

Dunno - just snapped a few pics around the room the other night. Oh, more:

Bout 2 1/2 years ago, not much changed, less lights:

See all those white stickers on the edge of the shelf above? This are from all the Shockers I modded.

That HF bench vise is pretty good for the price, I’ve lost my rubber things that were worthless anyhow, just keeping up the maintenance at your house would be a full time job.

Edit: Speaking of vise, I put my MH20 head in the freezer last night, bench vise ready to go, darn glue, would have forgot had I not seen that vise… Thanks

I keep moving/reorganizing all my stuff==the keepers—for sale etc—the other day my wife was in the space bath dressing area—I said wait be careful there’s flashlight parts in there

Jeez Louise is that the Boss 1 down below on the bottom right? What a chunk.

Oh, yeahhhh. the BOSS man. You know, sometimes you can find stuff in a picture you couldn't find when searching... ![]()

I had it out to take a throw #. Still up there, 649 kcd at 5m, but I've gotten well over 700 at 10+ meters with tuning.

Edit: Added wall beamshots to the OP of my review: https://budgetlightforum.com/t/-/42543.

Wow Tom. That all looks orsm. I even love the fact that you have a book on XML’s on your shelf. That is hardcore. ![]()

Thus used to be my home office - I used to work in there 7 days a week, 10-12 hrs/day. The books are all pretty much out dated, many I threw away to make room. Still working with XML today though, but C#/.NET wrap the details pretty well now. Used to be you had to know that stuff cold. I've had lots of contract gigs over the years, lots of different markets and technologies - wasn't easy to keep up.

So, what do you use the candle warmer for?

It’s funny, my office looks nothing like that. Even if I count all the Alkaline cheapies in my cars I’m probably under 25 lights total, and I only have about 4-6 batteries (toolpack pulls) that aren’t in a light.

The clear L6 really stands out in your pics.

Sorry to Haikelite for getting off topic

Candle warmer? You mean mug warmer? The mug warmer is my official PCB reflow surface - nice 80-100C or so temp to bring the PCB up to temp before reflowing. An EE friend gave it to me because he no longer uses it - he got a temp settable skillet that can do bigger boards and has better control of heat. He's been doing this stuff a lot longer than me, knows a lot more than me for sure - he's in to ham radio, rocketry (the big ones), doing side work like designing answering machines, etc., so does a lot of proto and small run work.

I'm to blame for the side track'n ![]() . Think we had a thread or two a ways back on home bench setups, but when the subject of sanity came up, had to post the insane pics I just took

. Think we had a thread or two a ways back on home bench setups, but when the subject of sanity came up, had to post the insane pics I just took ![]() .

.

I think I’ve seen them used as both candle warmers and mug warmers, but I guess that’s semantics lol.

I’ve seen those at thrift stores and wondered about them. Does pre-heating help in some way? If so, is it still beneficial on double-sided boards with components on the bottom?

Yes, but I typically reflow directly on the mug warmer, but usually give it a minute or so of pre-heat. It definitely effects the quality of the solder joint you will get. I'm no expert but look a little down on this page for "Insufficient Wetting" here: https://learn.adafruit.com/adafruit-guide-excellent-soldering/common-problems.

Some great basic info there. I used to buy my solder paste from a ham radio hobbyist who prepared needles with the good solder paste, and sell them to other hobbyists for a reasonable price. I explained to him basically what I/we do with flashlights and he was interested. I sent pics of the boards reflowed, and he picked it up right away, based on how the solder joints looked - he pointed out I was not providing heat to the boards. Since then, I asked around with the tech and EE's I work with and they all use some sort of means to heat the PCB prior to reflow, and of course all commercial shops do.

So will it work without heat? Most of the time, sure. Are you getting a proper solder joint? Probably not, and the trained eye can spot it easy.

I think I was getting away with it because I was using an embossing gun (which pushes a wide stream and heats up a little slowly) and usually I heat from the bottom of the board if I can. I should have a proper reflow gun coming this Christmas though, so I’ll probably grab one of those warmers too.