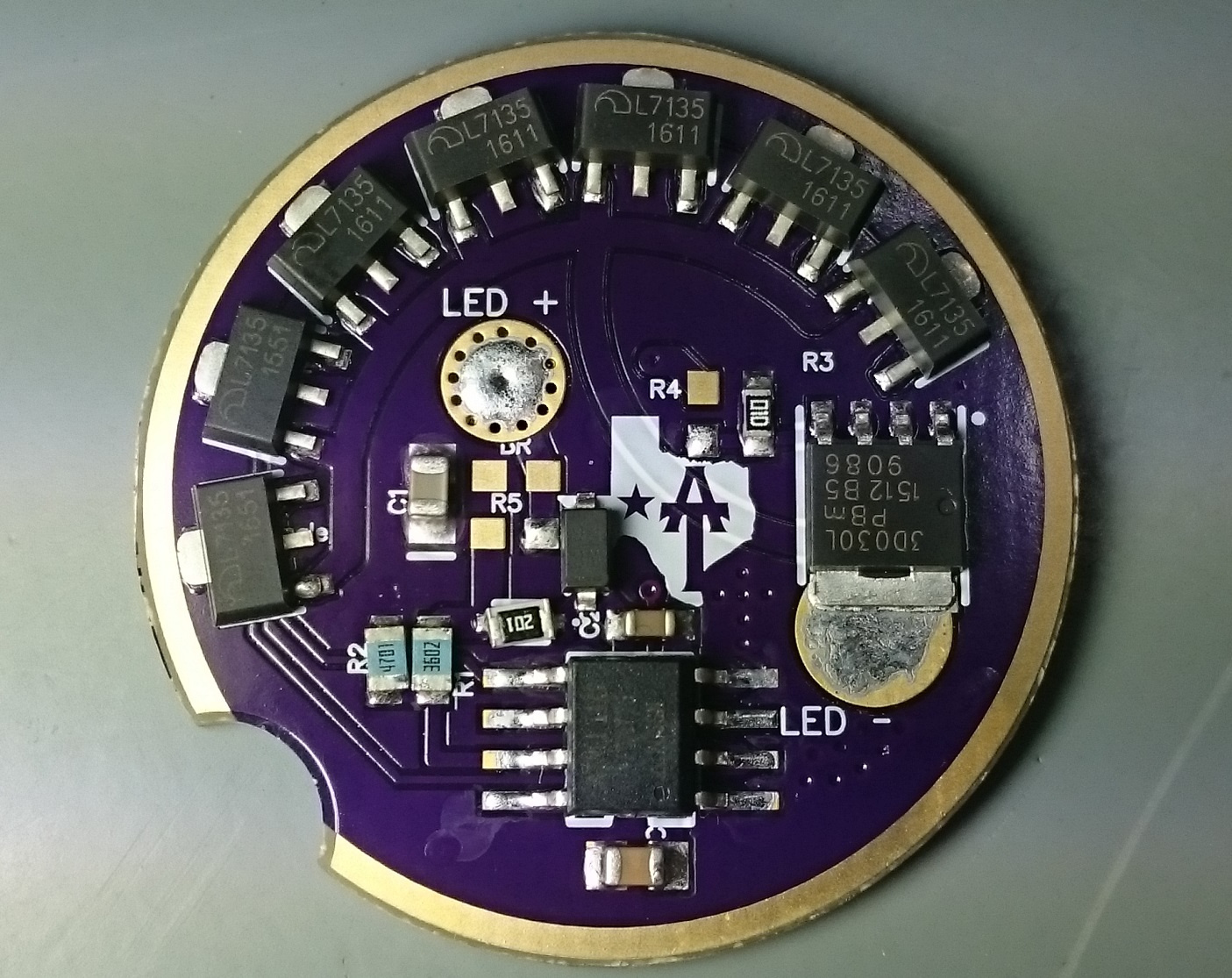

I posted this in DEL's OSHPark driver thread, but should have been done it here. Almost 3 years ago I modded a Yezl Y3 for my cousin's son who's into hunting. Frequently they are out before dawn and he wanted something powerful with some distance. I recommended the Y3 at the time. The original mod was a Nanjg nodded with a FET:

The switch eventaully gave out - didn't come loose, but internally there was no more spring action.

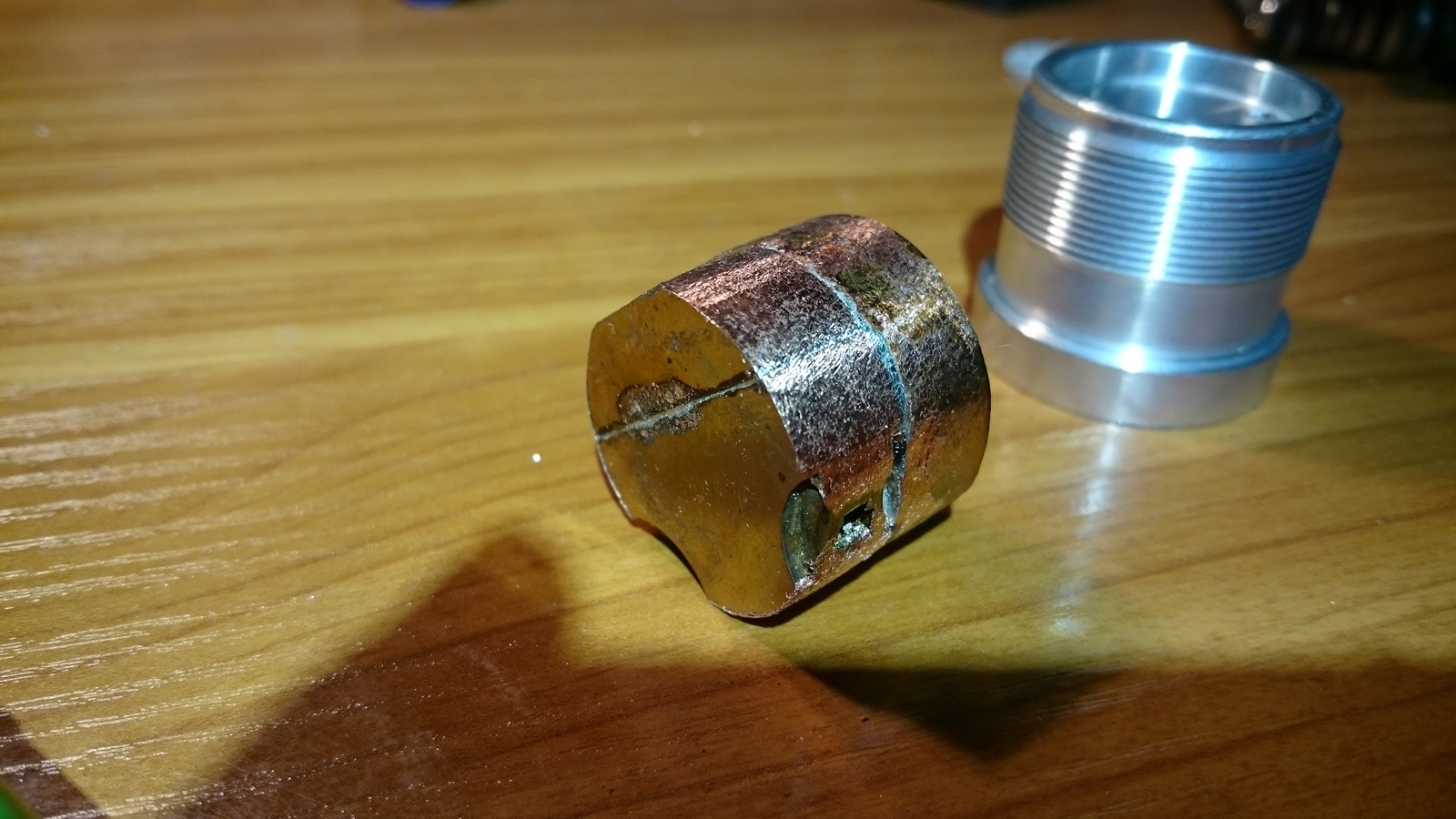

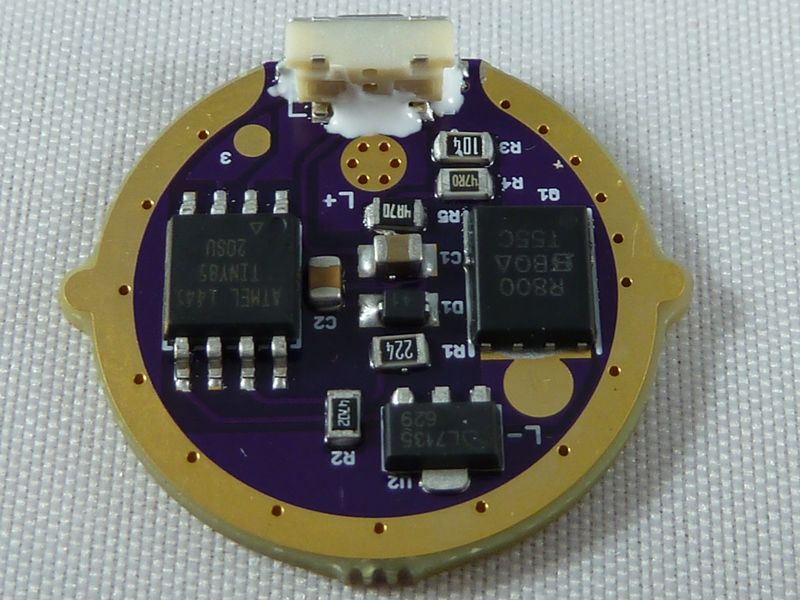

After it's all modded/cleaned up:

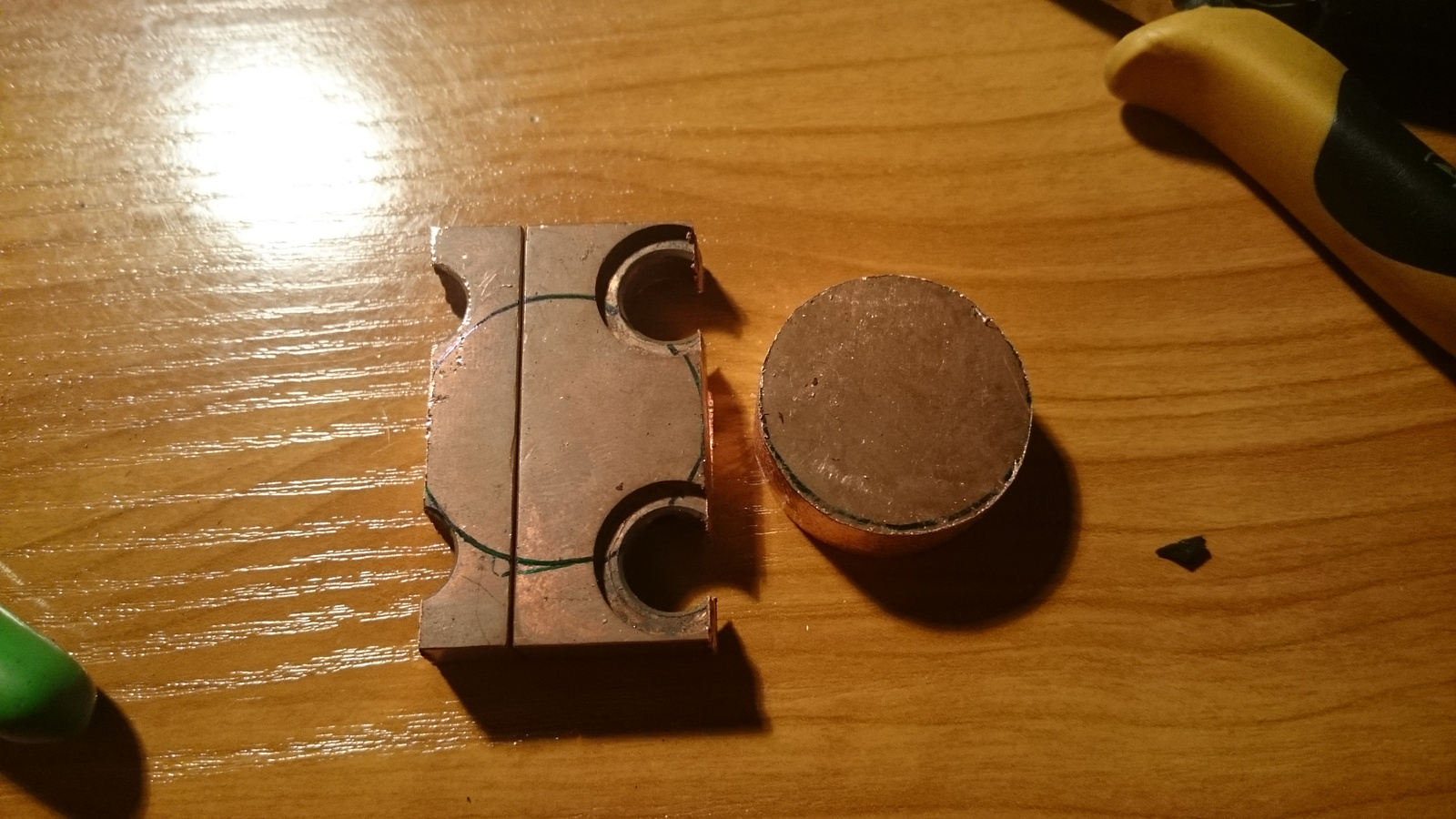

I did 2 boards. Will get to the 2nd some day:

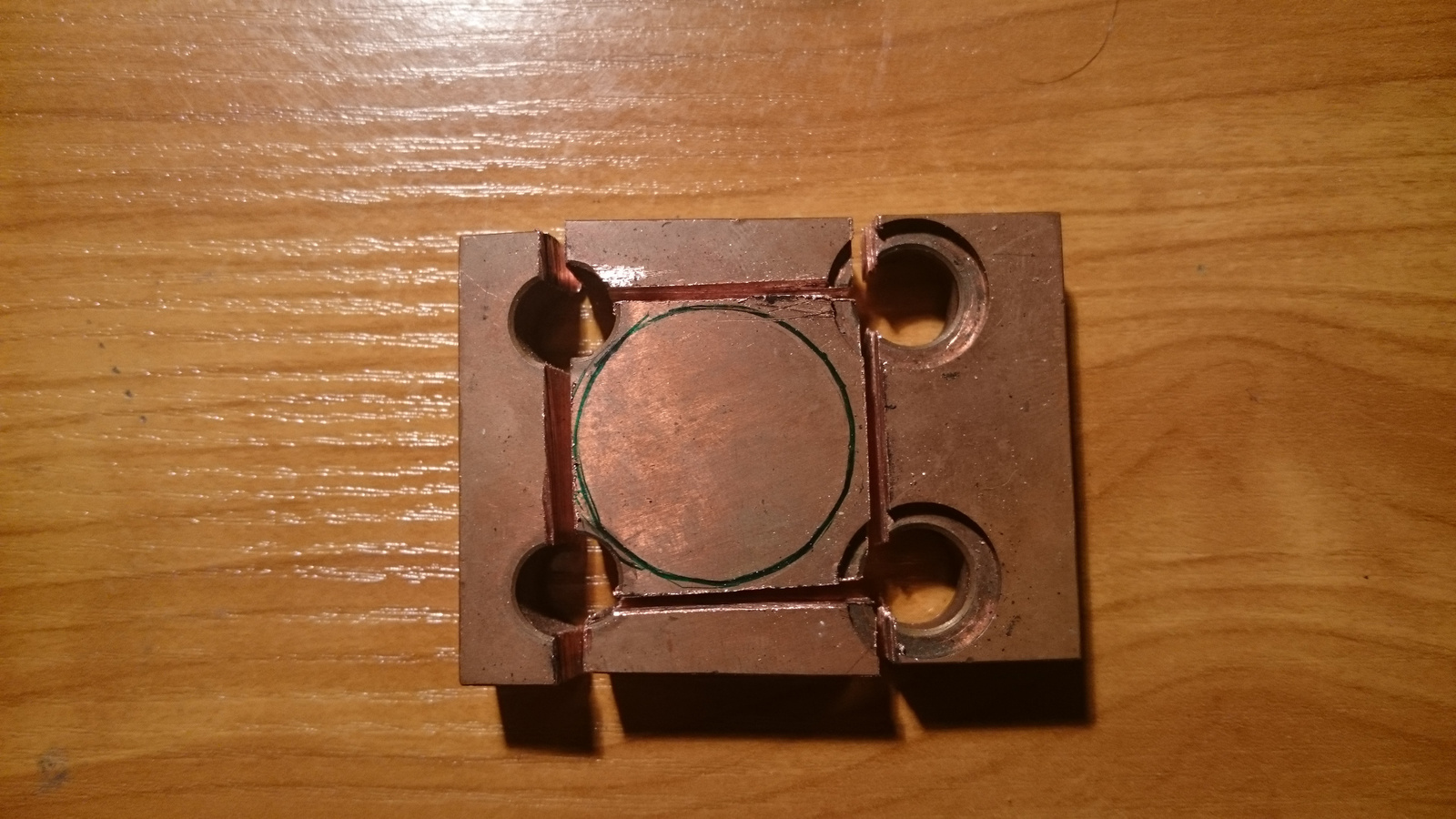

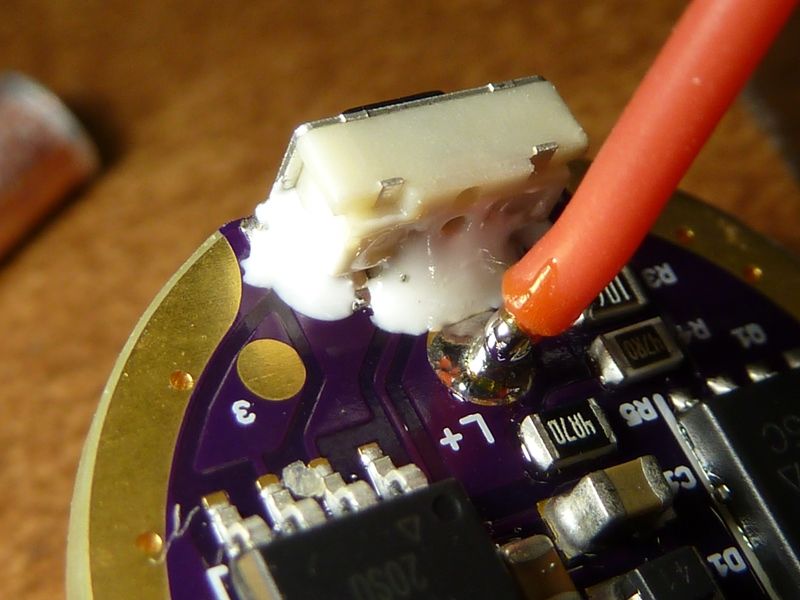

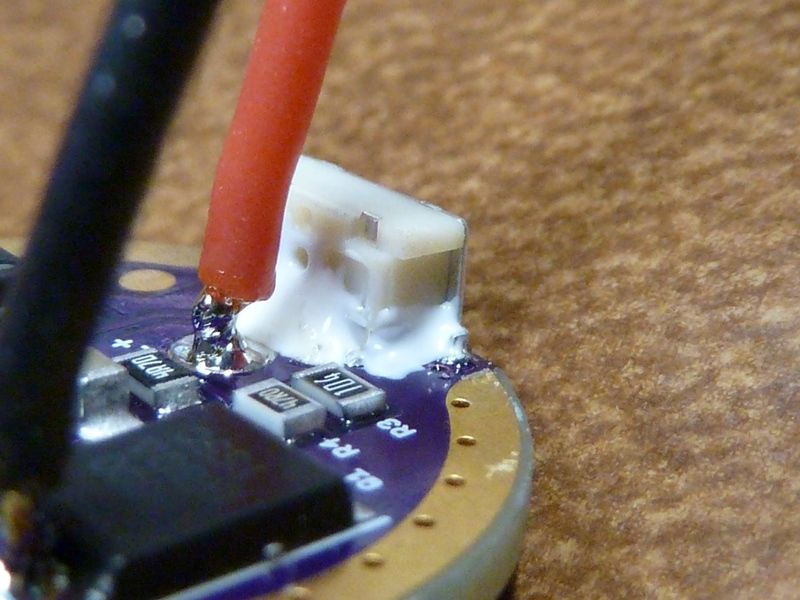

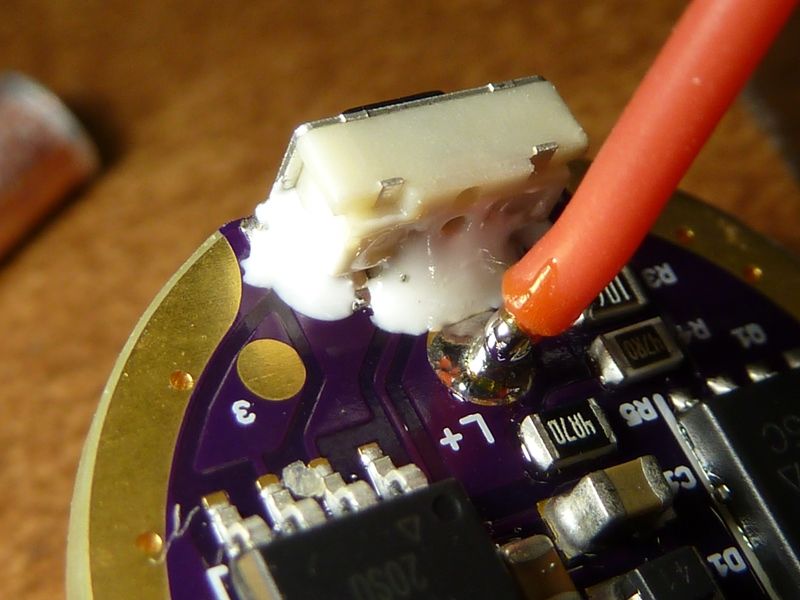

I used Arctic Alumina epoxy to sure up the switch:

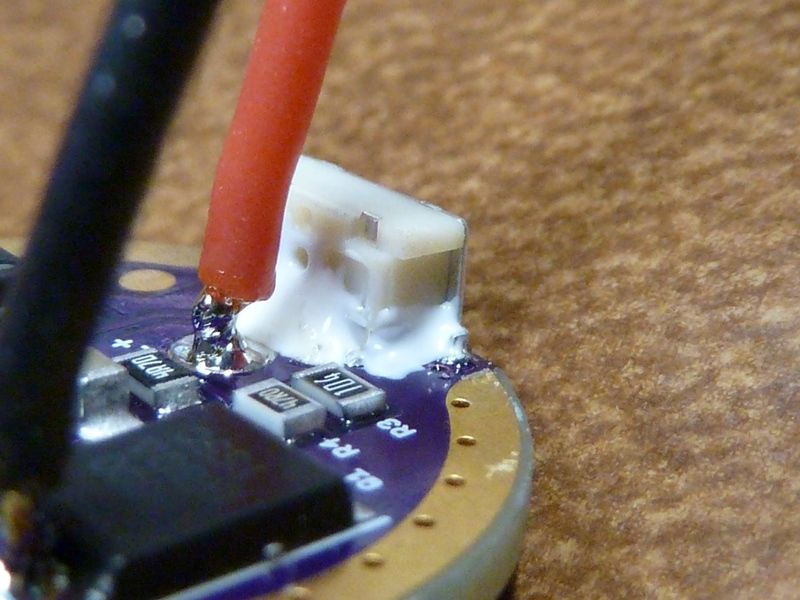

22 AWG bypass on the spring. I also applied some solder paste on one side of the LED+ pad, then the iron on the other - think the holes filled up well w/solder. The bypass is soldered to the pad with the thru holes, so minimum path to the LED wire:

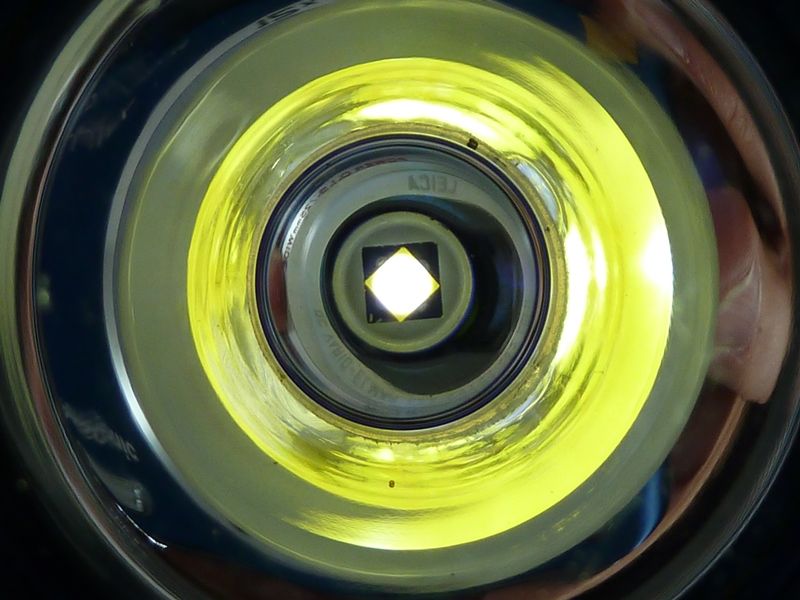

Seems to be my favorite LED right now. A KD XPL2 V6 3B, on a KD 20 mm MCPCB. Used 22 AWG because didn't think I'd get the clearance with 20 AWG. This is an early model Y3, and has a 23 mm wide flat reflector base. Later models I have use a smaller flat surface and different centering piece. The new ones need the centering piece significantly trimmed, sanded down, then the MCPCB is too low,so have to use a copper shim to elevate it. This one did not require a shim:

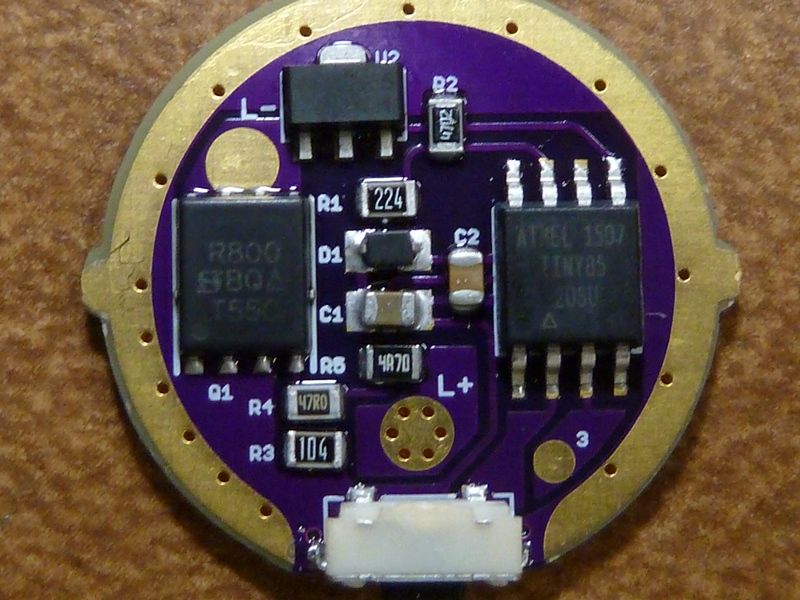

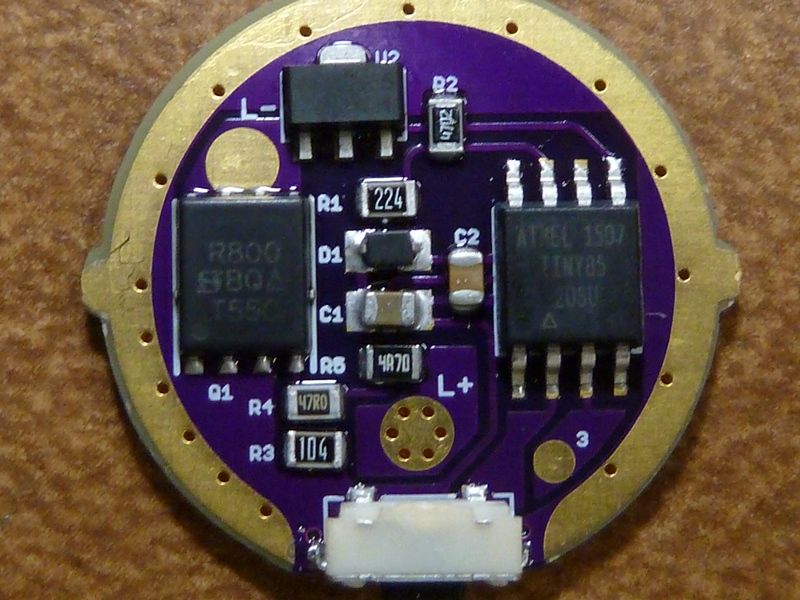

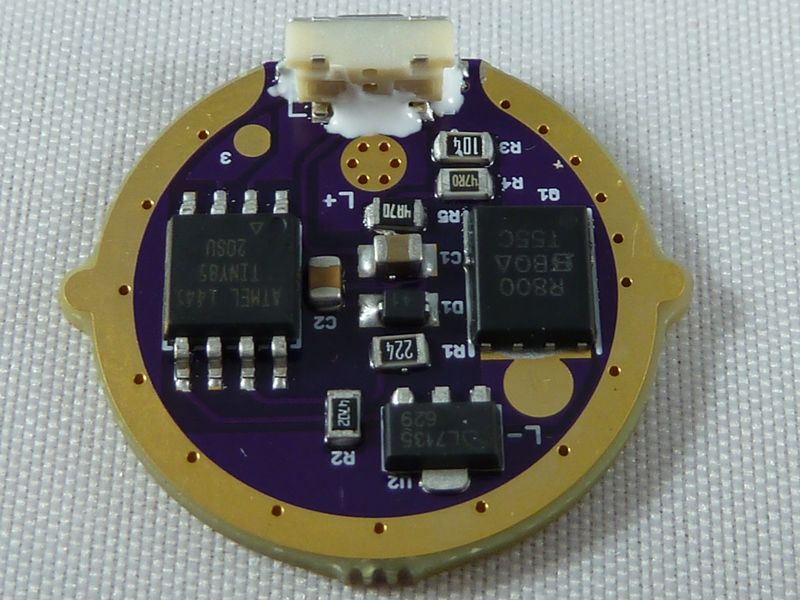

Here's a better shot in my lightbox studio on the 2nd driver:

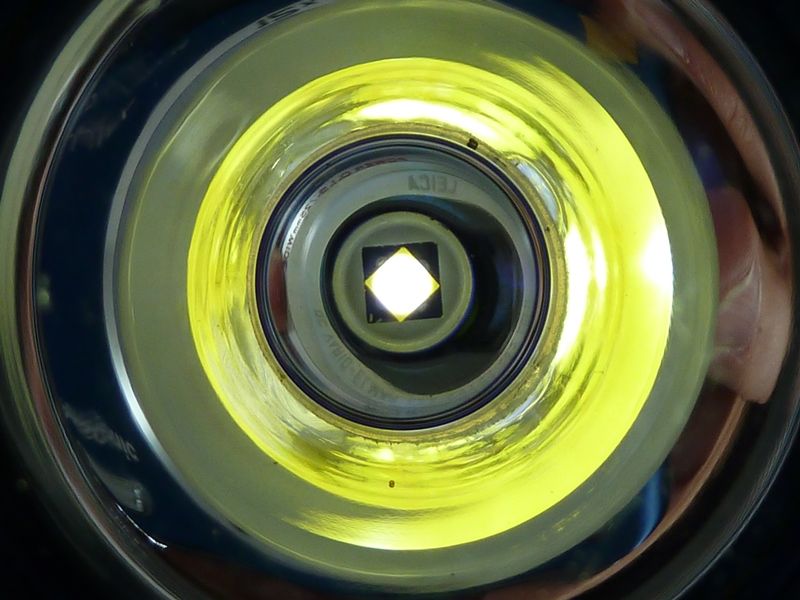

Assembled view of the LED, 2nd in moon mode:

The driver fit great, nice and snug with just a little filing. The results? Well, it's impressive:

On a LK @4.20V:

- 8.9A at the tail (clamp meter) - wow!

- 2,280 lumens @start, 2,150 @30 secs

- 123 kcd measured at 5m (700 meters)

Originally, this light had a Nanjg jury rigged with a FET on it, and a XM-L2 U2 1A domed. This was from May 2014. Originally, this is what it did:

On a SONY 26650 fully charged (best performing cell at the time):

- 5.3A at the tail (DMM w/heavy gauge leads)

- 1,680 lumens @start, 1,600 @30 secs

- 121 kcd measured at 5m (696 meters)

So it got a 34% bump in lumens @30 secs, barely measurable bump in throw. The XPL2's don't throw as well as the XPL or XML2 - I've seen this in couple of other mods.