SHAHE Digital calipers Product page .

I love measuring tools , especially accurate measuring tools . For about 30 years now I have owned calipers and I just don’t know how I could possibly have gotten on without such . Dial or Digital calipers may not be the most supremely accurate tools in the world , and there may be some variance from one to the next but that does not matter if you use just the one and as long as the measurement is consistent and repeatable .

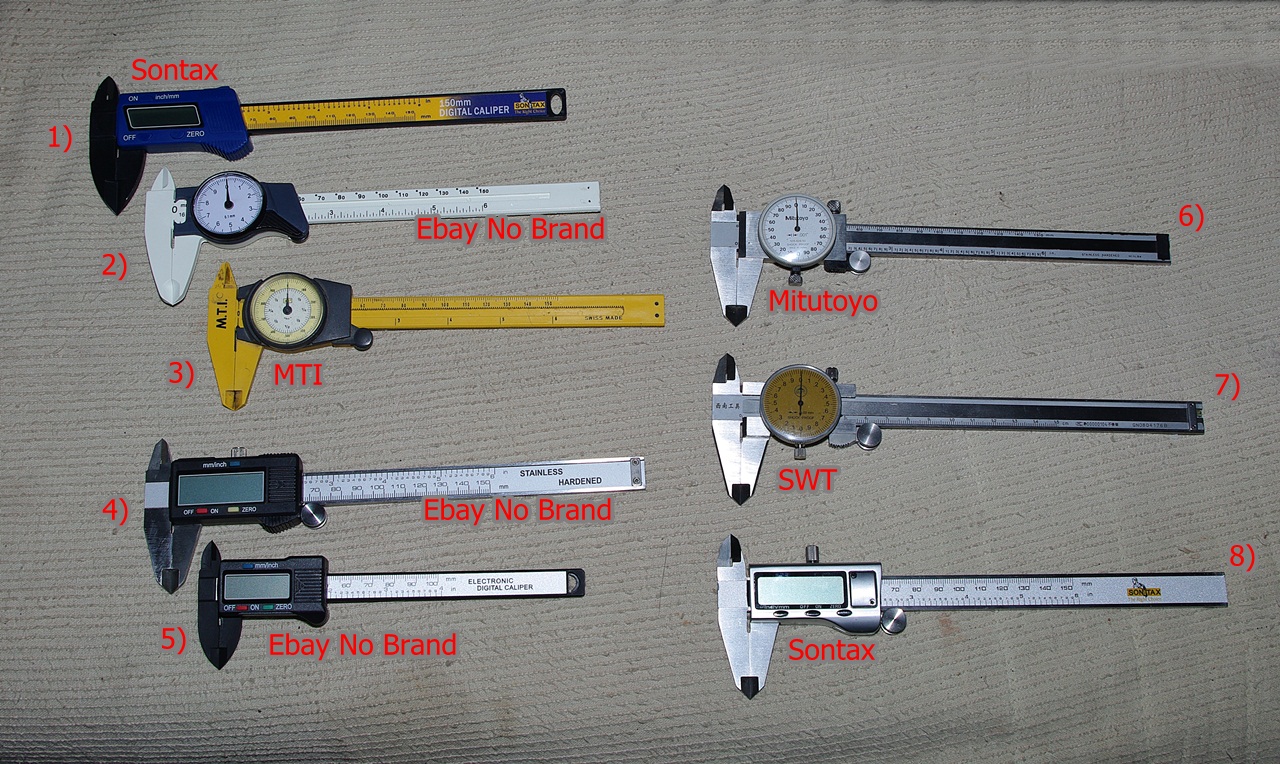

I have for a long time thought about a better or higher grade of digital caliper so when Banggood offered me the opportunity to review the SHAHE calipers I could simply not resist the opportunity . I have owned / do own quite a few calipers already and the idea of adding another caliper was just to good to resist . What comes in the plastic case is a very nice caliper / two batteries / a plastic tool for removing the battery cover / a test certificate / and instructions in Chinese .

Not sure how useful the instructions are but the calipers are very easy to use . Simply by opening the jaws the calipers will turn on , all the user needs to so is clean the surfaces of the jaws and zero the calipers . Then simply chose if you wish to measure imperial or metric . ( It really is that simple ) . Now since the calipers turn on automatically , how long does it take them to turn off automatically —- 6 minutes is what I got . ( That’s a little on the long side ) Another nice feature is the O ring on the battery cover to keep out fluids and other rubbish . ( A nice touch )

I did check the accuracy of the SHAHE calipers on a steel rod I have that’s been measure by lots of other calipers and I am happy to report that these calipers were right on the money . There was one thing I did not care for and that was the slop on the depth measuring blade . It really put a wrinkle on what was a really nice caliper . The screw used simply allowed for too much movement up and down in the recess the depth measuring blade runs in . I removed the screw and fitted a washer under it , there was still a bit of play ( a little more than I liked but so much better ) . So I very gently put a bit of a bend into one corner ( does a washer have a corner ? ) of the washer and made sure the bend was situated just over the depth measuring blade . Now there is very little slop .

Testing the depth measuring accuracy I put the caliper in a flat bit of knife blade and consistently got 0.0005 inch . ( That’s half a thou ) I really don’t know if you could expect better than that ? As getting 0.0000 could mean you are actually in the positive and don’t know it . ( If the depth measuring blade extended beyond the body of the caliper a thou or two , it would be hard to tell ) So from a accuracy stand point , I am tickled pink by the SHAHE calipers .

Now from a quality stand point , there is no play in the jaws . Movement is extremely smooth and for that I have to give full marks . But that screw at the tail end for retaining the depth measuring blade ? ( What the heck was with that ) It’s almost like some one design a really superb set of calipers and then decided not to try when it came to the tail of the calipers . ( Ok a washer fixes it ) . But why not spend that once cent for a washer and install it at the factory ?

With the washer fitted 10 out of 10 , without the washer 9 out of 10 . The SHAHE calipers are really nice , I mean nice . The USB data recording (?) I guess in a factory where you might be measuring hundreds of items it could speed up data recording greatly . ( Personally I have no need of such but then these are a higher grade of caliper - but that begs the question - what software to log the data ? ) Oh well !

Really smooth

No play in the jaws

Accurate to 0.0005 inch

Metric + imperial

Nice case

2 Batteries

Turns on automatically

6 minutes to turn off automatically ( ? )

Depth measuring blade is too sloppy at the tail end ( A washer fixes it )

Would I recommend these calipers , hell yes ! If you do a lot of depth measuring ? You will want to remove the screw that hold the depth measuring blade inside the caliper body and add a washer … ( You really want to ) . Look , 9 out of 10 without the washer , and 10 out of 10 with the washer .

I would like to thank Banggood for the opportunity to review / test the SHAHE calipers , thank you ( They really are great )