Low voltage warning is quite obvious on a DD light, it will get very dim, like <0.5 Lumens on a XHP70 when the batteries get below 2.8V

LVP shuts down the light in any case, LVWarning just reminds you to switch batteries, both is running in Narsil v1.2 fine for 2S

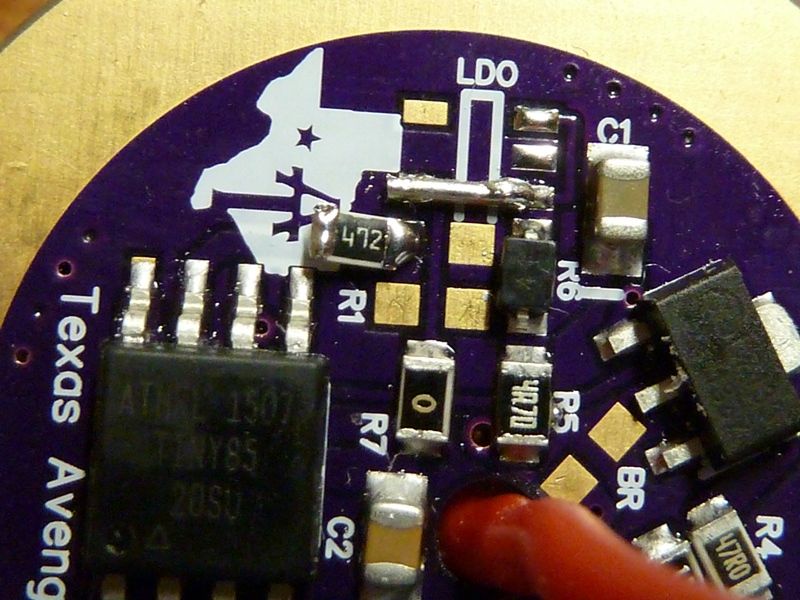

In 2S configuration the MCU does not see the cells voltage from Vcc of the MCU as it is regulated with the LDO

In Narsil v1.2 the LVP is on Pin 7 with a seperate set of resistors, no problem to flash this, but you loose temperature stepdown and indicator LED

in v1.3 and 1.4 he added there a indicator LED, those also have temperature stepdown

he is working very much on Narsil for the Q8, and will look into getting the 2S LVP

if he releases v1.5 I bet there is an option in the code to switch between indicator LED and LVP on Pin 7

it comes down that the Attiny 85 has a limited amount of IO pins, if it had more he would not have to remove the LVP in v1.3

The first 10 driver I soldered with an iron, took me about 35-40 minutes for each driver

This batch i will order solder paste and reflow em

I hope to get below 20 minutes per driver to assemble the driver reflowing

Bistro:flashing and testing Bistro adds another 10 minutes,

but a faulty one eats easily half an hour or more if you have to unsolder the 7135 for example if one is faulty

Narsil: Configuring code for different setups, flashing, testing, add resistors for Diodes and temperature calibrate the Narsil takes about 20 minutes

In both cases its possible to modify mode groups in source code if requested

or configure the driver as you like

It will add a little fee as it takes time

I calculated the prices above with about 10$ per hour just the time to assemble and test,

the first ones will be slower but with that many drivers I can reduce the time

the raw material costs for a 21mm Narsil are about 8$

there is no more parasitic drain on the 1 cell driver than the original Skilhunt driver

The LDO is only for 6V LEDs like XHP50, XHP70, or MTG2, with it the parasitic drain is also really low

just the 6V driver with Zener mod draws a few mA when off

as there are such nice LDO boards i would not recommens anyone a 2S driver with zener diode

a few hundred uA can be used for lighted sideswitch adding the bleeder resistor mid air and solder the LED wire on it

the indicator LED can be configured in Narsil to act as locator beacon, only this will increase parasitic drain, but the 1S driver got in any case LVP ad shuts down when the voltage drops betwenn 2.8 and 3V

you can read the manual for narsil, to see what a rich set of functions it has

the main settings are:

Setting # Function Clicks Defaults

1 Ramping Mode 1=disable, 2=enable; 2

2 Choose Mode Set 1-8 (1-7 is # of modes) – see Mode Sets; 4

3 Moon Mode 1=disable, 2=enable; 2

4 Mode ordering 1= sets low-hi, 2=sets hi-low; 1

5 Mode Memory 1=disable, 2=enable; 1

6 Turbo Timeout 1=disable, 2=30 secs, 3=60 secs, 4=90 secs,5=2 mins, 6=3 mins, 7=5 mins, 8=10 mins; 1

7 Blinky mode 1=disable, 2=one strobe, 3=all strobes/beacons; 3

the optional settings are:

1 Set Moonlight Level 1 - 7 (PWM value); 3

2 Active Temperature Regulation 1=disable, 2=enable; 2

3 Locator LED feature 1=disable, 2=enable; 2

4 Batt/Temp/Vers Ind. LED Only 1=disable, 2=enable; 2

5 Indicator LED Enable 1=disable, 2=enable; 2

6 Power switch modes w/mem 1=disable, 2=enable; 1

added