The Miller could you put me down for a 3rd one? Thanks!

That’s the definition of a sunk cost. People have great difficulty letting go of those, but it’s important not to let them tie you down to sticking with a bad decision.

Looks like the rush to get batteries is premature…

That’s true. But, in this case, I happen to think shortening the tube is a better decision in almost every way, and the “sunk cost” NOT becoming an issue is just one of the many reasons. :innocent:

Asked Thorfire if the smaller of the double springs can be made 2.5 to 3m taller so even short cells connect with them both.

Asked Thorfire if the smaller of the double springs can be made 2.5 to 3m taller so even short cells connect with them both.

mm i hope ![]()

This might explain the unexpectedly high readings of the protected GA cells tested.

Asked Thorfire if the smaller of the double springs can be made 2.5 to 3m taller so even short cells connect with them both.

That would make them connect to the ceiling ![]()

This flashlight is already perfect. I can mod my flahslight and bypass the springs. Can I have it now in this form? I need it now. How about a presale groupbuy for those like me who dont want to wait another month or two (or 3 or 4 or 5) till it is perfect?

This should not take very long

If my measuring is correct 2,5 mm longer small springs should connect having both springs take current and temp.

Or another solution with the springs for that does not require design changes on main parts.

I would just bypass springs so no problem with current and temp.

Is there option to do it in factory?

Maybe n my old SRK, two of the springs were shorter right from the factory. It was easy to work around by putting a magnet on the bottom of those two cells. Maybe short cells should have a similar spacer when used in this light?

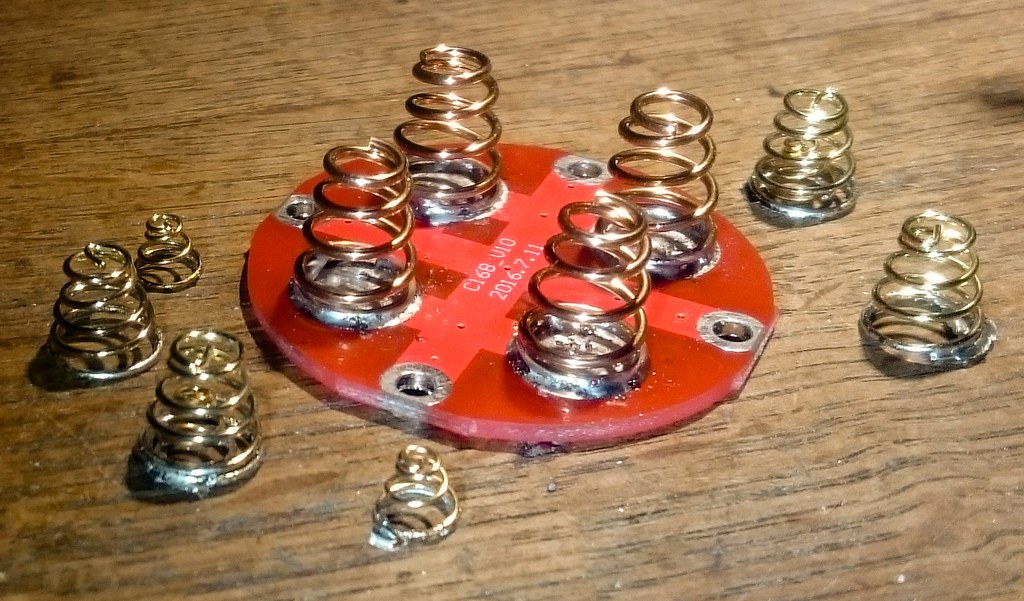

Because one of my proto3 springs was toast anyway, I decided to replace them all. The only springs that I had that were the right size and nice stiff were my phosfor-bronze ’djozz’springs, so they went in:

This is how it looks now (VTC6 batteries, same length as 30Q’s) :

The batteries sticking out over the (shortened by a few mm!) tube so the springs are compressed well, and enough travel that long cells fit too.

Because phosfor bronze has one-third the resistance of steel, the out put went up too (not neccessarily what I desired), on VTC6 batteries 6130 lumen now (30 seconds). My 30Q’s are in the charger now, numbers with them later.

Oh that is nice Djozz!

So hope it is good with this solution!

Oh that is nice Djozz!

So hope it is good with this solution!

I hope that Thorfire is willing to source beefier springs, my springs btw are 10mm base diameter, 15mm height (13mm after the first compression, it stays 13mm after that).

We could show Barry the above picture with the VTC6 batteries.

If you get the same or better lumens, please mail these pics, they fit, require 1 solder action and only 1 spring instead of 2.

If you get the same or better lumens, please mail these pics, they fit, require 1 solder action and only 1 spring instead of 2.

I get better lumens but the output can not be compared, these springs are made from phosfor bronze which has 3 times less resistance than spring steel. What we can only ask for are steel springs with these dimensions, so they will give less output than these. Asking for phosfor-bronze springs of these dimensions is useless because they are not readily available in China, this was one custom batch made by an Amsterdam spring manufacturer.

But considering that my output numbers of the proto3 when it was still stock were done with the small inner spring not engaged, using a bigger steel spring will give similar numbers (the thicker wire will compensate for the longer length of the wire).

Charger was ready, output on 30Q’s is 6200 lumen now.

This should not take very long

If my measuring is correct 2,5 mm longer small springs should connect having both springs take current and temp.

Or another solution with the springs for that does not require design changes on main parts.

How hard would it be for them to move the driver board back, either by shimming or not machining as deep?

Spring height

uncompressed 9.22mm

compressed max 3.23mm

small spring also toughing at a spring height of 5.41mm (I measured this wrong in previous post)

Depth tube from flat tail PCB is on to driver ring 73.93mmCell length possible

64.71 - 71.70mm

Cell length needed for double spring action

68.52 - 71.70mmI think the 30Q bt cells are ~66mm between -metal and +button

So these don’t engage thesmall springs

how about the big tail spring of the S70S?

13.76mm

4.69mm compressed max, no grinding of metal it just becomes a nice dome with spiral looks

Option #1. If we swapped these taller springs in, the longest protected cell that would fit would be 70.2mm. Would that be acceptable?

Extending the battery tube 2mm would allow for 72.2mm protected cells (plenty) and still compress the shortest cells an extra 2.5mm compared to the existing springs. This seems acceptable.

Option #2. Is to keep the flashlight as is and make the short cells longer. You could solder blob the bottom side (I’m not sure this is safe since it’s closer to the chemicals inside the cell) or use some type of spacer. A magnet like TK suggested (Thorfire selling the light with 4 magnets included?) or a simple penny dropped down onto the top of the spring.

Since we are still designing the light, the smartest solution is to make the light fit all cell sizes.

Option #3. What is the longest protected cell length? If it is less than the 71.7mm we have now, lets say it’s 70.5, then Thorfire could shorten the battery tube 1.5-1.7mm and it would still fit, barely, and the shorter unprotected cells would get an extra 1.5-1.7mm of spring compression. This depends on the longest protected cell length, though.

My vote would be Option #1

(with Option #3 being a close second, assuming it’s feasible)