The Miller, if you look up close at the last pic of MRsDNF of the different reflector sizes, you can see the steps milled on the GT’s reflector outside surface, I bet those are the reason we see rings on the wall beam shots from inside the reflector, I am guessing that maybe they are removing too much material on each pass of the CNC machine…

The most impressive beam shots of a reflector light I have ever seen. Thanks for the trouble Steve. Lumentop along with our BLF designers has stepped to the front of the pack with this one. Step aside Thrunite, Olight, Fenix, Jetbeam, and Acebeam.

Can’t stop laughing on this !!! :laughing:

As I am old enough,I prefer cool white tints.I can look better with them.So,is it possible that I take one with CW tint?

Nice pics MRsDNF!

Hahaha with the C8 reflector on top ![]()

First response to CW option is “no just one led choice to keep it easy” but given the difference of 10% we could talk about it in the team, will come back to it.

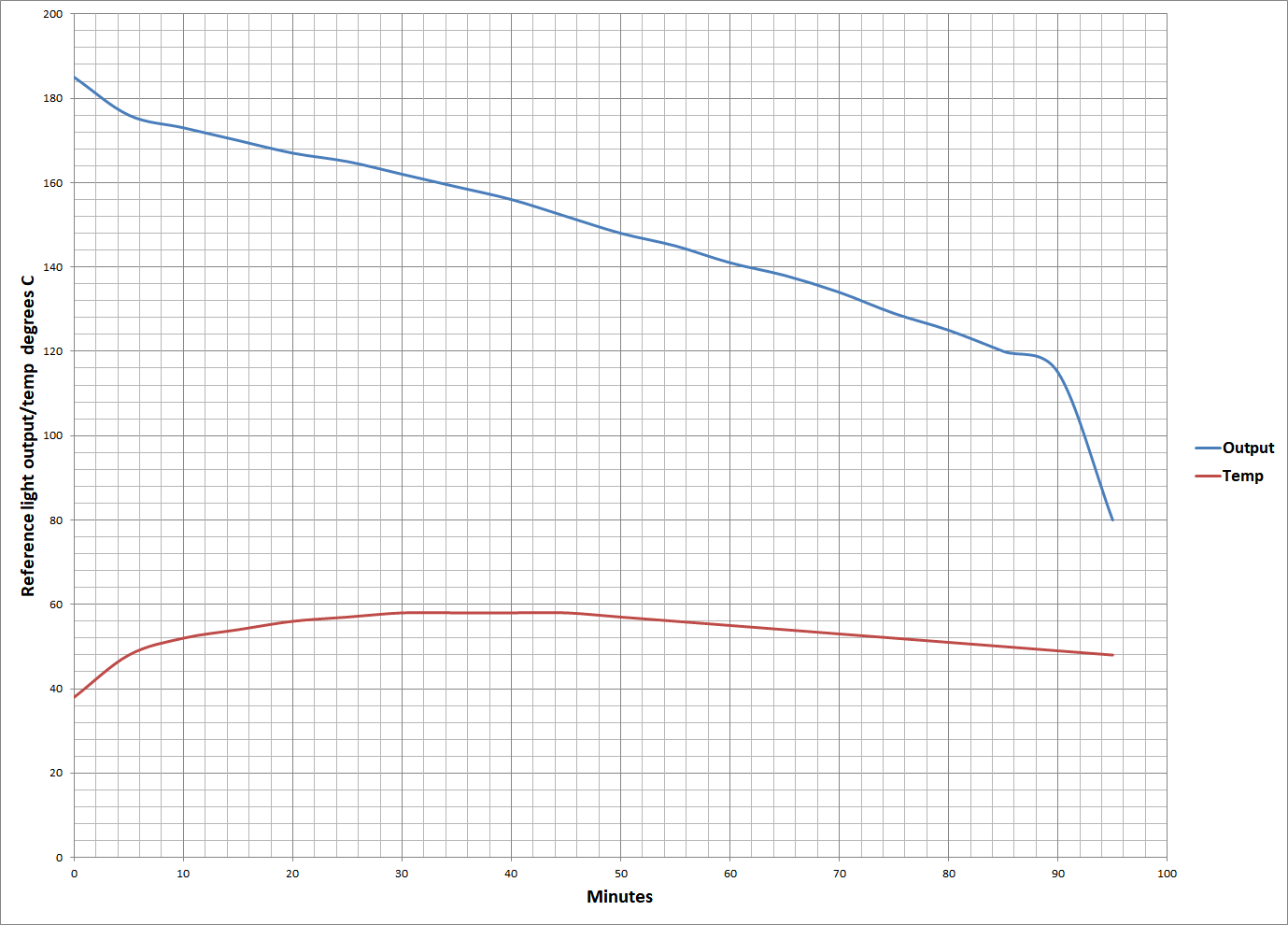

The run time test below was carried at with Kaidomain protected 3500mAh batteries. 30Q run time test was also performed.

There was only a few percent difference in output between the two different batteries with the 30Q just ahead until the 45 minute mark where the KD 3500 pulled ahead.

The low voltage protection kicked in at the 72 minute mark while the 3500 KD batteries lasted until the 94 minute mark before low voltage kicked in.

The rested voltage of both types of batteries was around 3.5 volts.

I’d have no hesitation in running this type of protected battery in the GT with my tests.

I was thinking that the GT was going to have some sort of regulation like the K70… ![]()

Runtime graph credit goes to member Selfbuilt on CPF!

I’m not sure Alex. Maybe the electronic guys can chime in.

K70 use bust driver therefore it must be regulated, while with buck driver like in GT performance will drop as voltage drops. But this testing was with short tube and 4 batteries,

so with 8 pcs runtimes and voltage drop will be twice better, 180+ minutes with 3500mAh batteries

It really looks like a great flashlight, I regret not having been listed on time, the lights designed in the forum are always special and unique.

Its not to late to put your name down in Millers thread. You may have to pay a little more though.

Great tests MRsDNF!

It is clear there are voltage losses, as the others wrote, “again it is about the springs” ![]()

The carrier needs some work, if losses are less regulation will be longer. Of course not running on max will keep it in regulation longer.

Yet for a first prototype and just four cells this already is pretty nice!

That output graph looks really bad for a buck driven flashlight…

It should be able to maintain a perfectly flat output without overheating at that size, since the battery voltage is not going to affect it.

The TN42 has very flat output over time, and it also gets hot.

Even though it doesn’t drive the XHP35 as hard, it has a lot less heat dissipation too.

Something seems very wrong….

Is the led current measured already in the prototypes?

I hope we can find a better driver for this light, it does really deserve flat regulation at 100% output. In this case I guess it is better to go 2S2P and use a boost driver.

If you want a really high quality solution the Senser Extreme from pcb components could work. I think it’s a bit overkill though.

There's more info to come. There isn't much overhead for bucking when driving a XHP35 HI at 2.5A (high Vf is the killer). Near flat regulation can be achieved though, not for the full discharge though, and lower performing protected cells and the springs in the stock prototypes don't help. With only 4S, the buck will only last so long before it falls out of regulation.

Thanks Tom.

Coil-type springs that also carry current as well as apply mechanical loading are sure to be a problem when attempting to optimize efficiency and performance. What if we used bent-tab style contacts as springs? Like in this style of carrier? As long as they are thick and strong as well gold/silver plated then contact resistance will be low. You can make them of spring steel and still have fairly low resistance due to a relatively high cross section and large contact patch.

The first post in the Q8 thread has links to prototype entries, some of them have beamshoots