![]() :+1:

:+1:

It got smoother & shinier overnight.

Now, where’s the rest of this light? ![]()

Looking good already! :sunglasses: :+1:

I completed the first stage of my wall of bookshelving and have a couple afternoons free before getting back to that home project, so I got back to this light project today.

Here is that first part I made and the section of wood I will cut the next part from.

I’ll be using about 6 inches of this if I only have to cut once. This piece has slowly been getting smaller since I bought it about 25 years ago. Then it was about as long as I am tall, a few inches under 6 feet.

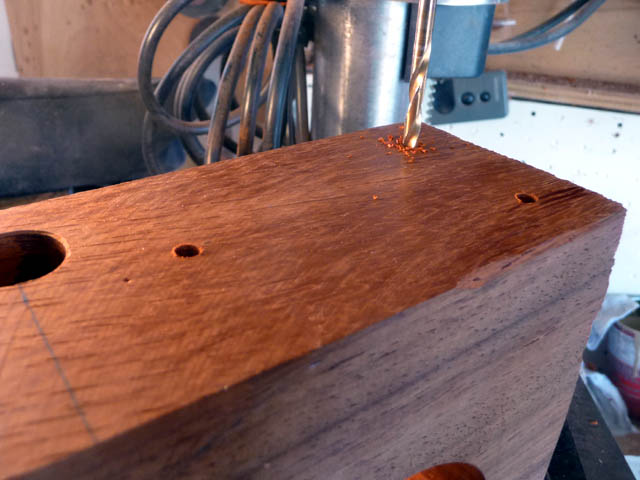

I’ll be making a hole with this drill. 3.25” (about 8.25 cm)

The clamp makes a decent safe handle

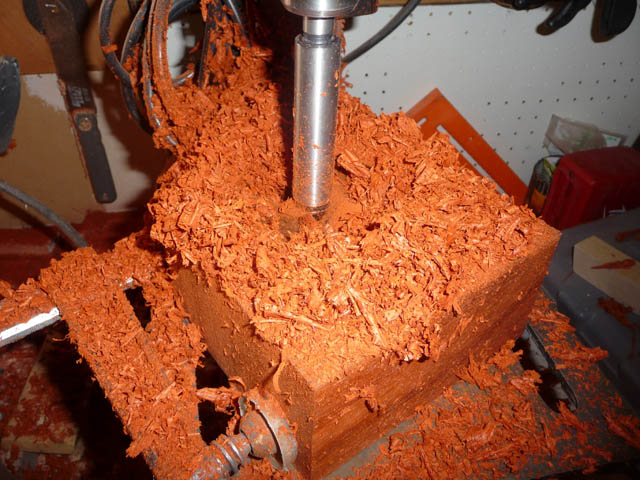

LOTS and lots of shavings!

Drilling takes a while as I stop and let the bit cool every half inch or so. Can’t use a water or lubricant bath as with metal. Pity. The bit needs a sharpening as it is also making a lot of dust as well as shavings.

For the curious… this is the base board I used under the padauk block to prevent tearout as well as to keep the bit from hitting the cast iron drill press platform… The drill cuts shavings between 0.4 to 0.5 mm thick.

That’s all for now. Thanks for looking.

Curious to learn and see where it will go ![]() Good work :+1:

Good work :+1:

If you ground/sanded a taper toward the shank on that hole saw boring bit you have there (I’d like to know what it’s actually called) you will get rid of most of the heat issues. HSS really doesn’t like heat, for wood you could try wax as a lubricant. Also peck drill and high rpm.

That’s some drill bit! And a nice chunk of wood :+1:

The drill bit is a Forstner bit, invented about 150 years ago by a Benjamin Forstner. Usually they do not have a toothed rim like this one, just a circular rim. They are meant to cut/drill a flat bottomed hole. The flat bottom holes have a slight dimple in the center where the centering spur protrudes slightly. This one was specifically sold as a clock making bit… drilling a recess in a wood blank for a small battery powered analog clock movement. With a drill press you can drill overlapping holes, even drill at an angle if the work piece is clamped down to the table.

What CRX said. The block of wood is a lot bigger than it looks in the first picture on my phone.

nice start .keen to see the result

Progress measured in small increments…

I needed some more holes, so…

My under 2 inch forstner bits

Two holes done and my newly arrived Q8 ![]()

3/4 of the bookshelves project done. 1/4 to go as a corner cabinet to the left. Then I’ll be free to do the waiting flashlight stuff unimpeded till the next (inevitable) project.

Wow wow, wood is so last year ![]() just kidding, I’m looking forwards to seeing the built!

just kidding, I’m looking forwards to seeing the built!

Are you filling the bookcases full of flashlights? ![]()

If it was my own, probably. But I’m building them for our son’s place. FYI, they will end up with sliding Japanese Shoji doors. They look a little like a window with a lattice framework. Instead of transparent glass traditionally they use translucent paper. We will be using a laminated paper for greater longevity. LED strip lighting will be run behind the lip of each shelf. They will be dimmable.

There will be real books. ![]() Who knows what else? Maybe a Q8 if I can bring myself to give one of mine away. :person_facepalming:

Who knows what else? Maybe a Q8 if I can bring myself to give one of mine away. :person_facepalming:

Back to this years contest entry….

More holes needed…

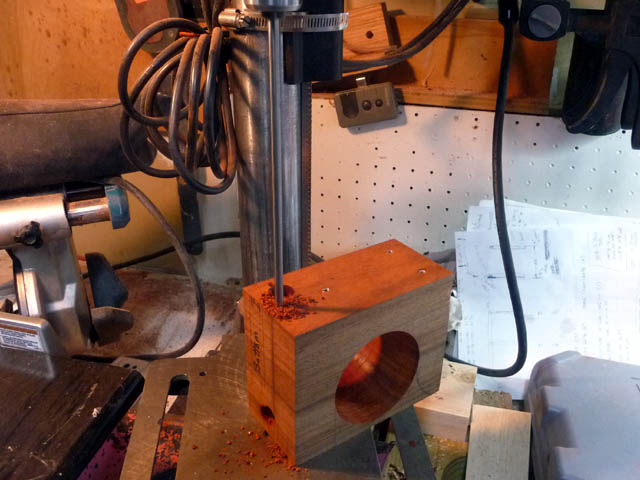

After drilling those three holes I sliced off a slab with the table saw. Then drilled out the holes in the block and pressed some aluminum threaded inserts into place.

Another view of the block and plate. When completed the plate will be mounted back onto the block face.

I need a round copper disc, 3/4 inch in diameter for a cell contact. Using aviation snips I cut one from a scrap of 0.020” copper. This is the rough blank.

A file was used to remove the excess and round it off

That is a piece of 3/4” walnut dowel used to check roundness and size. Looks okay to me.

More later.

Holes and grooves…

Using a very long 1/4” bradpoint bit

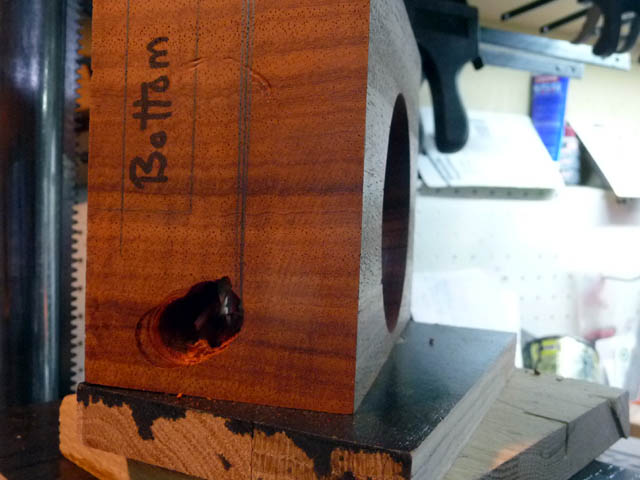

The drill tore out at the bottom a little, but that is going to be hidden from view, so it never really happened ![]()

I need some grooves to run wires in. Never tried this before so here goes…

As well as the Dremel cutting wheel I used a Dremel cutting burr and a small Dremel drum sander.

More to come another day.

Very nice Don. Do you glue the threaded aluminium in or just press fit it? I’m learning lots about different drill bits as well. :+1:

It is a tight slip fit. I use a bench vice to slowly squeeze them into place. I did not use any glue on these as I don’t think I’ll ever torque the screws heavily enough to worry. When I feel the need to lock them more securely I use a triangular file and file a small groove down the length of the aluminum insert. Then when it is in place a drive a small brad, or finishing nail into that groove. It locks very well.

I used to have some special cyanoacrylate glue that was made to allow making a slip fit. Made by StarLoc, Wet one side like the wood hole, drive in the insert and in about 5 minutes it would set. I still have the empty bottle, but have not found anything like it. Haven’t looked hard though. I bought it from a UK seller a couple years ago.

Good to see some more progress, Don :+1:

I’m back in Aus after spending the last week or so in the US on vacation, & have a lot of catching up to do; both reading BLF, & working on my DIY build….

…that reminds me, MRsDNF wanted some Drag Week pics….

Yes please. ![]()