Is the tint also better when FET is running with lower duty cycle (e.g. with 1 Ampere) - or only when FET is near 100%?

Very difficult to see because the tint change that I think that I see goes together with a large brightness change and a brightness change alone already makes your eyes perceive a different tint. So yes, I think it is already better with FET at low duty cycle but the effect is not at all obvious.

If it depends on high current it might be another point against triple channel drivers. After using several lights with Nichia 219C 4000K CRI92 I’m pretty spoilt with tints.

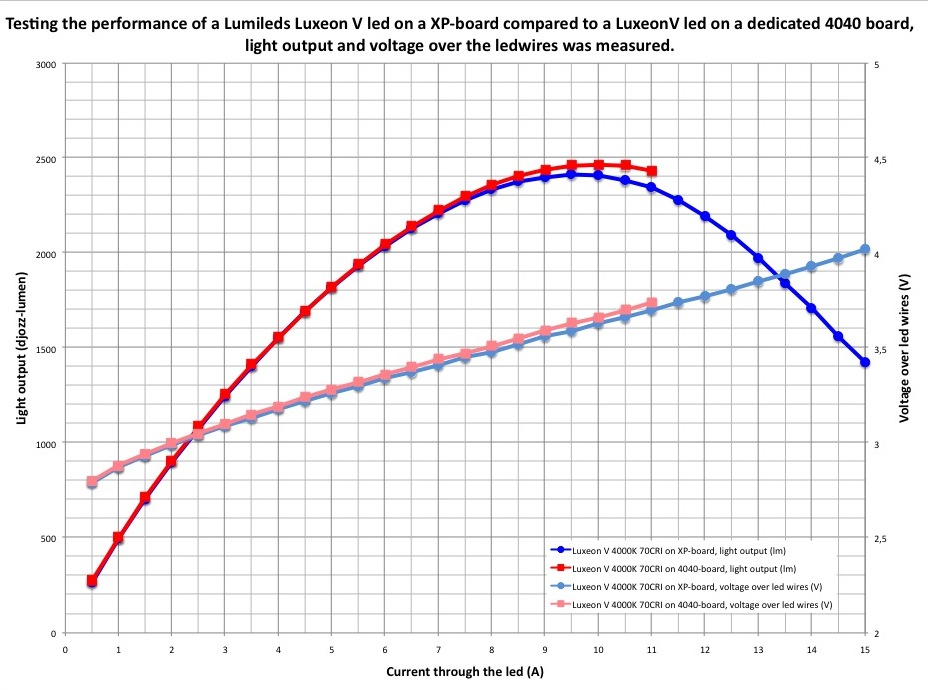

I crunched the numbers, here’s what I measured, LuxeonV on a XP-Noctigon compared to LuxeonV on led4powers 4040 board. They were different leds so some difference could be expected regardless on which board they were. But the performance on the lower currents is so identical that I’m inclined to attribute the slight difference at high currents to the boards and not to the difference between the leds. I checked the quality of the reflow after the test by desoldering the led and checking the solder pads for incomplete reflow, everything looked fine.

My conclusion: the 4040-board has the slight edge, but only at very high current. But apart from performance, the 4040 board makes reflows way way easier and robust.

I wanted to be gentle to the led to be able to use it afterwards, so I stopped the test at 11A, but looking at the chart it looks like the output decrease when the current is over the maximum-output current is clearly lower on the 4040 board. This suggests a healthier led in case of abuse when a 4040 board is used.

Thanks for the numbers!

Would like to see this LEDs in my D4 …

Hey I just noticed this, but “a thermal resistance of 0.8 degC/W, which is 3 times as low as any existing high power led” is not really correct, the CFT-90 has a thermal resistance of .45C/W at the junction.

But this is probably because the LED chip itself is like 10mmx10mm or something huge like that ![]()

Hey I just noticed this, but “a thermal resistance of 0.8 degC/W, which is 3 times as low as any existing high power led” is not really correct, the CFT-90 has a thermal resistance of .45C/W at the junction.

But this is probably because the LED chip itself is like 10mmx10mm or something huge like that

Yes and no. ![]()

0.8°C/W is by far the best value ever for a 4mm^2 LED (XM-L2, XP-L2 etc. => usually around 2.5°C/W).

Luminus has traditionally reached the lowest thermal resistances because they use larger DIEs and a special direct-to-copper mounting technique (notice that they have two sets of bond wires, the current doesn’t got out the bottom of the DIE).

Generally LEDs with large DIEs seem to have lower thermal resistances. I think it makes sense to compare thermal resistances relative to the Die size, so I multiply them (so lower values are still better):

XHP70.2: 0.9°C/W * 14.2mm^2 = 12.78

CFT-90: 0.45°C/W * 9mm^2 = 4.05

XHP50.2: 1.2°C/W * 8.24mm^2 = 9.89

XHP-35 HI: 1.8°C/W * 5.9mm^2 = 10.62

Luxeon V: 0.9°C/W * 4mm^2 = 3.2 (I had to guess here regarding the DIE size)

SST-40: 2.5°C/W * 3.994mm^2 = 9.99

XP-L2: 2.2°C/W * 3.55mm^2 = 7.81

XP-G3: 3°C/W * 2.06mm^2 = 6.18

Osram Black Flat Gen2: 4.3°C/W * 1,122mm^2 = 4.82

So it seems the Luxeon V and the CFT-90 are indeed very good, but the Osram Black Flat, XP-G3 and XP-L2 certainly hold their own.

I’m not sure theses theoretical values tell the whole story though or even have any meaning at all. I am completely ignoring the size of the LED package and thus of the center solder pad. The Luxeon V has a larger solder pad compared to the XP-L2 and the SST-40 is even larger than the Luxeon.

Today I tried the Luxeon V 4000K 70CRI in my black Emisar D4 (see the WDYMT thread). The output and beam were very rewarding, but although it still looks alright, the tint is better in the VG10. I can’t say for sure but I expect it is a reflector vs TIR thing, the hotspot from the TIR is more yellow, and the rosy appearance in the VG10 beam is not obvious in the TIR beam.

Also, while playing with both flashlights, it looks like the tint is better (more red in the tint) at high current when the led runs on the FET than at low current when the led runs on the 7135.

I’m using the D4 with Luxeon V’s everyday now during a short holiday on Schiermonnikoog. Despite the very small margins between the solder pads on the ledboard because of the non-fitting footprint the light holds up fine and proves to have a very good and pleasant tint for use in a natural environment. Actually in showing contrast and depth it does no worse than my E2L with 4000K R9080 219B’s.

But I still feel a bit lonely using this led, is there anyone else who has used the Luxeon V in a flashlight? Experiences?

I built S2+ with 9A LD-A4 (+ thermal enhancement kit) and Luxeon V on 16mm DTP, it works nicely,I'm seeing highest lumens from 4mm^2 die LED with absolutely great tint, it's pretty unbelievable this LED is only 70CRI,it has quite a bit of red in spectrum and beam is very uniform across emitting angle, also tint is very consistent over wide range of current. CREE XP-L V6 3D tint looks pretty crappy compared to Luxeon V, and it has less output too (fast drop due to high Vf).

Djozz, the same depth and contrast as 319b sounds great

Do you think it is a candidate for the FW3A?

. . But I still feel a bit lonely using this led, is there anyone else who has used the Luxeon V in a flashlight? Experiences?

Been trying to join you, but the footprint is frustrating me in my chosen target, the Q8. It looks doable. Sorry for the off angle of the picture. Seven reflow attempts so far. All seemed dead on. The last few reflows were just one emitter, the other 3 excluded. Always shorting the positive side. Even if I hold the emitter from where it wants to sit.

If I want to keep the stock mcpcb, I think I will have to modify the pads slightly.

I have many different XP boards in my spare box and the solder pad size and position vary a bit, to the point that on some the electrical pads are too far to the middle to fit the Luxeon V at all. Perhaps the Q8 board is one of those ![]()

Just ordered 3 mounted on the 16 mm's from Led4power. That looks wayy too challenging even for me to mount on a XP board.

Just checked - these are 4.0 x 4.0 mm, bigger than XP's, smaller than XM's. Soooo, guess stock centering pieces won't work?

Rotating XM-L spacers should work .

XP-L V6 3D (EE X6) vs. Luxeon V 4000K (S2+) white wall

Luxeon V 4000K beam

Been trying to join you, but the footprint is frustrating me in my chosen target, the Q8. It looks doable. Sorry for the off angle of the picture. Seven reflow attempts so far. All seemed dead on. The last few reflows were just one emitter, the other 3 excluded. Always shorting the positive side. Even if I hold the emitter from where it wants to sit.

If I want to keep the stock mcpcb, I think I will have to modify the pads slightly.

Has anyone tried cutting away some of the center pad with an exacto knife?

Now that is proper led surgery! ![]()

(no I have not tried that)

Interesting idea FmC. Sounds promising.

I modified the Q8's MCPCB to fit the Luxeon. Just used a utility knife to remove the solder resist on the outside of the pads out to the overflow tabs and to remove just a slight bit of the coper trace on the inside of the pads. It wasn't pretty, but it works. Measured about 8.5k lumens at start up which dropped down to 8K about 20-30 seconds (wasn't timing). I had also swapped out to the A20DP FET. The tint as has been reported by djozz and others above is so nice. As led4power stated, it's really hard to believe the CRI is only 70.

In addition to mcpcb's, we are going to need new isolator rings. I ended up using some xml isolators and drilled out the Q8 reflector some. Unfortunately, I was impatient and used a dull bit. Messed up some of the reflective coating at the enlarged emitter holes. Luckily, the beam pattern seems unharmed. Just not so pretty right now.

Thanks djozz for bringing this emitter to our attention. I think this may be my new favorite emitter.

EDIT: I should note that the Luxeon V's measured above went though at least 8 reflows until I got them all properly connected. I don't know yet if all the heat hurt their performance. But at a minimum, these are tough emitters. If I get a chance tonight, I'll get a couple beam shots.

EDIT: Sorry folks. It was raining last night. Looks like it will continue to rain with the tropical storm that is moving up the coast.

That is great and perseverent work ImA4Wheelr, and some bravery is required to attack the nice Q8 board with an exacto knife, I know how wrong it can go when you cross the dielectric layer when going too deep.

For clean reaming reflector openings for fitting centering rings I succesfully use a hand reamer. Mine was a really expensive one (the brand is PB) but I never regretted buying it, I use it often in modding.

The numbers that you get are as expected exactly 4 times the numbers of my VG10 with the LV.

^

Thanks for the tip on the reamer. I haven't ever used one. Will look into them.