it sure does work, i’ve build few uv lights using pmma tir lenses. have leds run for hours, no issues whatsoever.

i thinki know what picture you talking about, however it shows carclo triple, which is made of polycarb.

has nothing to do with luck, polycarbonate lenses are ok from 400nm, and up, never had any uv led damage lenses, but than i never drive them beyond reccomended current, in most cases i drive them with even less current, uv leds are not nearly as tolerant to heat as white leds, so no overdriving, 365nm will be fine with pmma, done it more than once.

I just tried the polycarbonate (clear safety glasses) and paper trick. It did reduce the fluro pop some. I then tried with/without the optics and there didn’t seem to be much difference. Does that mean I could’ve used 365nm without issues?

paper will glow at basically any wavelength, even blue light makes it glow a bit. find something else to test, id, or money, or something else that reacts to 365nm, but not to higher band.

also, are you sure your tir is not a pmma one? such 7up lenses are made by different brands, and some no name brands. also pmma is basically an acrylic plastic just not as brittle, acrylic does let lower than 400nm thru. simple common Plexiglas is acrylic.

I don’t follow?? Why do I need to test with 365nm specific colours when I have 400nm?

if you have 400, then forget about testing it, it will work with any lens\tir

Aah, so my question remains unanswered.

the answer is no, you do not need to test with 365nm specific colours when you have 400nm

You cant test a lens with 400nm and then use 365nm and think it will work

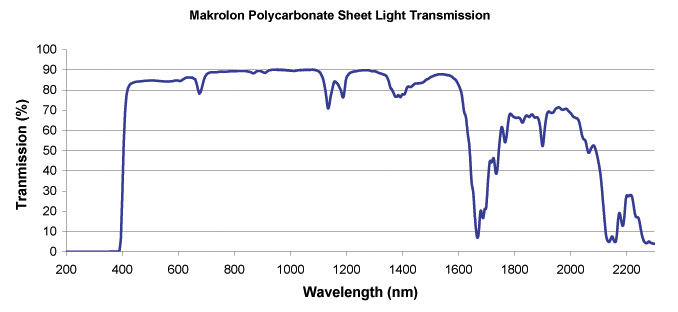

PMMA woks down to 385nm, Polycarbonate 405nm

It is quite simple if you test a lens or TIR with 400nm with paper of course the paper will glow as the material transmits 400nm very well

But if you go 365nm or less what looks to your eyes and 400nm as transparent becomes black as it absorbs the light

Absorbed 500-1000mW in a few cubic mm of plastic resulted in a molten and burned optic, unfortunately this picture is gone with photobucket

the pic is still there, it is polycarbonate carclo. he said he used 395nm leds to burn the tir, no indication how hard he was driving it . my guess he was driving it above recommended current. but i might be wrong

https://s17.postimg.org/tbyqf3qrj/DSCF6042_2.jpg

He said he thought they were 395nm when henput them in the lght, but they were 365nm, end result dead tir and LED domes garbage

This was the question I was referring to and Lexel has just answered it for me. Thanks for all the info guys ![]()

Nice mod pp. I love your persistence in reflowing the leds. Did you use an oven?

Thanks Moose ![]() I used a blow torch to heat the head, see second pic. There is a hole in the plate allowing the hot air to pass right through to the switch and wire holes in the head.

I used a blow torch to heat the head, see second pic. There is a hole in the plate allowing the hot air to pass right through to the switch and wire holes in the head.

Impressive stuff. :+1:

Nice I like one like that to look for vintage Vaseline glass . Shine rhat no need to turn out the lights. That’s an awesome build.

Thanks maildroid ![]() I had to google Vaseline glass :student:

I had to google Vaseline glass :student:

aka. uranium glass?

I used to shine my uv onto those special edition fluorescent mountain dew plastic bottles(goes by the name mountain dew neon) and they glow up pretty nice. I heard paqlite also glows pretty well.

If only they had a blue bottle then I could turn it into a nuka cola quantum. :innocent:

Update: I’m now planning to mod this replacement bottle cap led with a 5mm uv led and make glowy bottles

Looks like a cool project indeed :+1: Keep us informed with it :disguised_face:

absolutely I will. :+1: