Well this really reveals my newb status. I got a driver from Mtn Electronics and when I soldered to the negative pad, the pad actually lifted up and separated from the driver board. So I got another one and it is doing the same thing. Is there anything else I can solder to once the pad lifts off like that? Or can I superglue the pad back and try soldering again (quickly!)? I did manage to successfully solder the positive wire and the spring.

I don’t have advice on how to fix the pad coming off. Is there a reason you dont want to order the drivers with spring and wires already ran for a 1.50 more? I think he uses 22 gauge wiring for them. That’s how I order them.

I’ve had a wire come unsoldered from the driver a couple times when I had a short, and springs melt. But the wire went right back on the driver.

Maybe you could tin the driver and wire tip before trying to solder them together? Or maybe someone here will know if there is another spot you can put the negative wire? As long as it grounds I’d think it would work. But I maybe wrong on that

I’ve had the same thing happen to switch leads (they’re tiny pads) for mtn eswitch boards. Luckily the one pin i delaminated was also pin 2 on the chip. I just moved it there.

I’d say less heat and a smaller tip.

After you tin the pad, blow on it to let it cool. Then tin the wire. When you go to join the two, just heat the tinned wire with the iron and let that wick the solder from the pad. That should decrease the heat to the board.

Last two boards, this worked better for me.

I trashed one in the process.

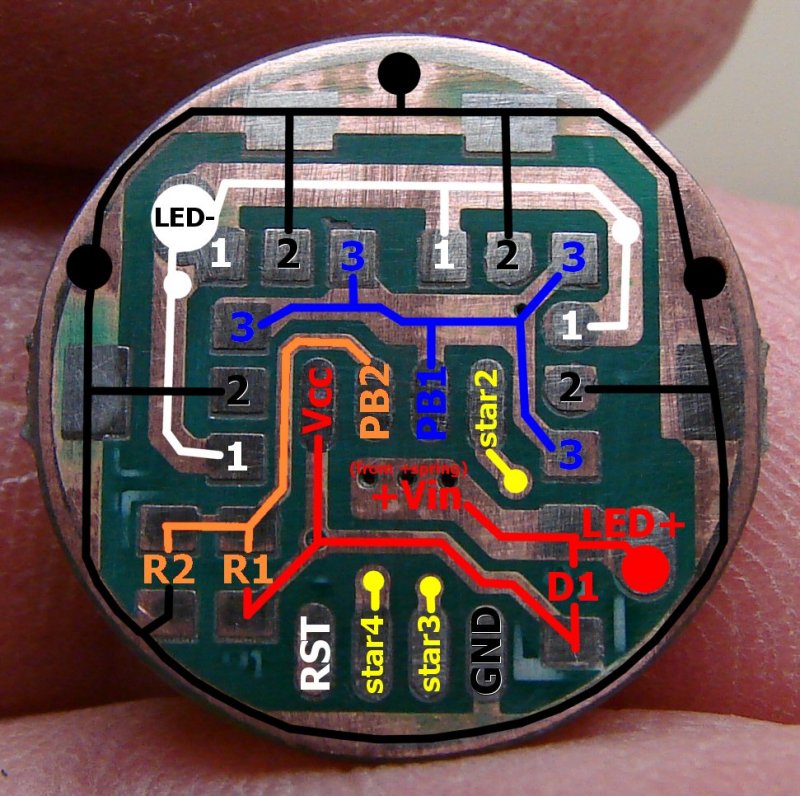

To salvage the one in your pic,check to see if that’s just a common ground. You can grab that elsewhere if it is. Grounds all over the boards. Check for continuity to other spots that are also grounded.

If thats a amc7135 that I see on the left in the photo you can solder directly to that pin that’s beside the pad.

If its not take a pic showing the whole driver.

Thanks for all the good advice. I did try soldering to the leg of the chip next to it and the first time around that didn’t seem to work. I will check it further. I will also try looking around for another ground if that isn’t working. After I messed up the first one I did message Richard and asked for wires and a spring on the next one but he said they haven’t been doing that on this driver for years (you’re on your own kid…). It’s the cheap one sided driver, which is all I needed (or so I thought).

If that’s a amc7135 that’s the output pin, if that doesn’t work then something else is wrong.

.

I’m having a hard time seeing the separation in the picture. I’m not aware of a way to repair a PCB.

Which driver is it? I’ve soldered, and re-soldered, and re-soldered several driver boards from Mountain Electronics without any issues.

Isn’t the gold ring around the outside of the driver also negative? Just solder to there?

What are you using to solder?

After many years of making do (and ruining a lot of stuff) I finally got an actual, temperature controlled, workstation.

OH MY what a difference!

Not endorsing this site or this item, just showing what I personally bought

I’ve found that for this sort of application, a pretty hot tip and a “fast touch” works well for melting solder but not messing up other stuff.

I also have a small fan running right nearby that I point at the work after the “solder touch” to bring the temps right back down.

Also, in these sorts of things, flux is everything for making a good joint. If it ain’t clean it’ll mess up later.

That is battery ground. That bypasses the 7135 regulator and becomes direct drive.

.

Comfy’s pic

Oooh right

It’s the Nanjg AK-47A driver with 3x7135. Yes, it is a 7135 right next to the pad. Sorry it doesn’t show the pad lifted as much as I would like. I kind of pushed it back into place hoping it would stay there. I am just using a standard 30W iron with a fine tip. I did have the tip pressed against the tinned wire and then tried to quickly press the solder to the pad. As you can see I lifted all the solder off the pad and must have heated the board enough so that the pad separated. Just not fast enough yet. I am just hoping there is a way to salvage this driver.

Repairing a broken track is feasible, but it is more work than youll want to do for what that driver cost. Just solder to a different ground. If you do want to lay a new pad down it involves epoxy and removing some of the top layer of the PCB board to access the conductor underneath, its a bit involved.

Seems like your Soldering Iron isn’t hot enough——if you have to stay on that wire more than a few seconds—not enough heat