There is no parts list, I will sell those for a fair price

I spend a lot time to make it work that way and designing the boards

I will make them with a max current and option for 2 potentiometers that can tune about 30-100%

The boards are the easy part, tuning the LEDs was quite time consuming

Biggest thing is you literally need for each LED and each max current of the bord different values

I measured this to find the right values that took a lot time

The LEDs are from various chineese shops and likely not all the same

of course if you do not get the same LEDs the resistor values wont match

First I tried it on my regular 6x tail boards with conventional 6 Balance resistors and a 1kOhm Bleeder

Main Problem was that with low battery voltage the higher voltage LEds (Blue, White, pink, ice blue) get dimmer tan the low voltage ones (red, yellow, green)

I came up to enhance this idea with a voltage regulator, but had to do some steps to make it work

first get the voltage and resistor value for each LED at the same brightness

Then I made some calculation to get fixed current draw versions

But when I made the prototypes I saw that this is pointing in the right direction

but a lot manual changes were needed to equal them out on different board currents

It is also possible to use this with side switch lights like Convoy L6, as I can get the parasitic drain for the 18kOhm bleeder down to 0.4mA when the tail board has 0.15mA for the LEDs

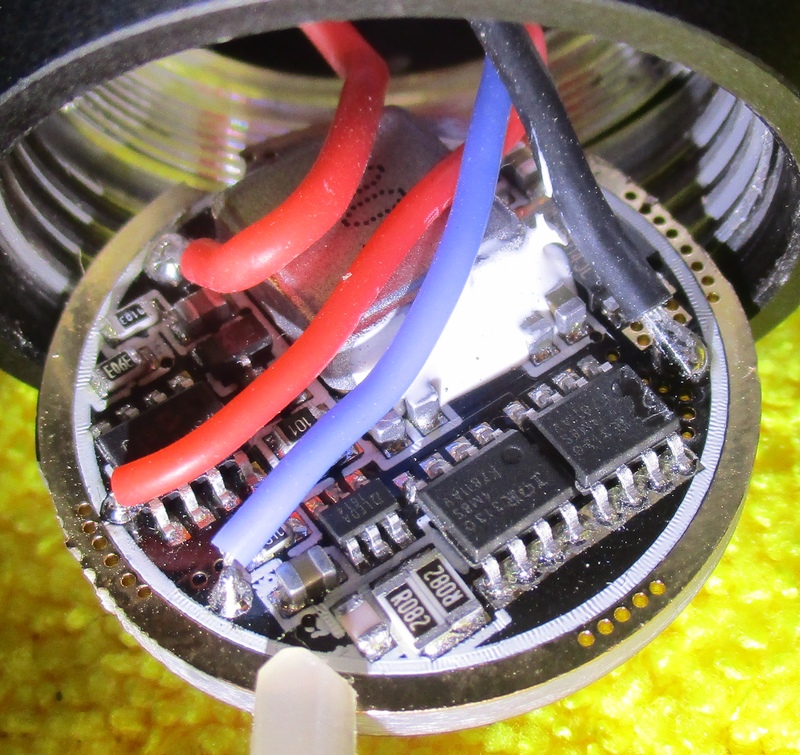

Now the first 4 Prototypes

I did quite some measurements and tests to even out the brighteness of them

Firt L6/L2 prototypes are build and successfully tested on my bench, modding the lights will follow

One tme i skipped the very current hungry Emerald green for a warm white

The tail board itself uses a voltage regulator so the brightness is constant down to 3V cell voltage and can be fitted with 1S or 2S voltage regulator

The 2S Voltage regulator has a 0.1mA higher drain

I haver also ordered fitting 3x3mm trimmers so that the brightness of the board can be adjusted for 2V and 2.5V LEds in 2 groups

On the other hand I can also build em with a current draw from 0.15-1mA with the balance resistors without trimmers

The rainbow LED boards have one drawback which are the inefficient Emerald green and yellow LEDs,

so their brightness is lower than green or white LEDs at the same current

The LEDs are all measured by me and trimmed to equal brightness

The thing is adding the tail cap cover I also saw some colors do not get equally through it, so again minor changes were needed

Is there any easier way for me to test the driver though?

Is there any easier way for me to test the driver though?