Ok so I found out two things:

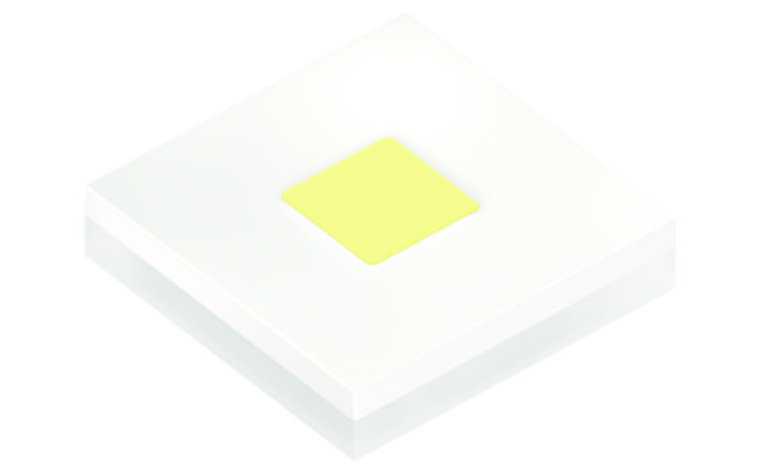

1) The KW CSLNM1.TG (image A) has a smaller lm and cd value than the KW CELNM1.TG (Image B) simply because the datasheet has a larger bin range for the second one. The website then lists the average lumens and candela as the (min+max) / 2 making it seem like the CELNM is better.

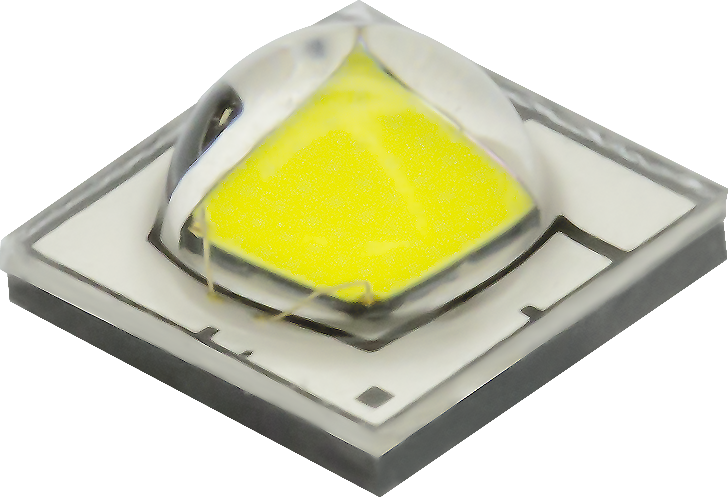

image A, CSLNM)

image B, CELNM)

Even though the CELNM may have a higher bin, we likely will never have a chance to purchase those anyway, so effectively it is the same as the CSLNM.

2) Also, as expected, you can see in the datasheet that the smaller thermal pad does hinder the overdriving ability, as the curve only shows 1.7x output at 2 amps, where the CSLNM has 1.75x output.

For this reason, the CSLNM is a much better choice because not only does it perform the same, assuming you get the same bin, but it has the same thermal pad as the black flat allowing it to be used on XP-size boards and gets better overcurrent ability than the CELNM.

As for the performance compared to the black flat, lower thermal resistance only seems to make it maybe 0.05x higher output at 1.5A when compared to 1A according to the flux-current graph. The main benefit will be not having the notch in the corner.

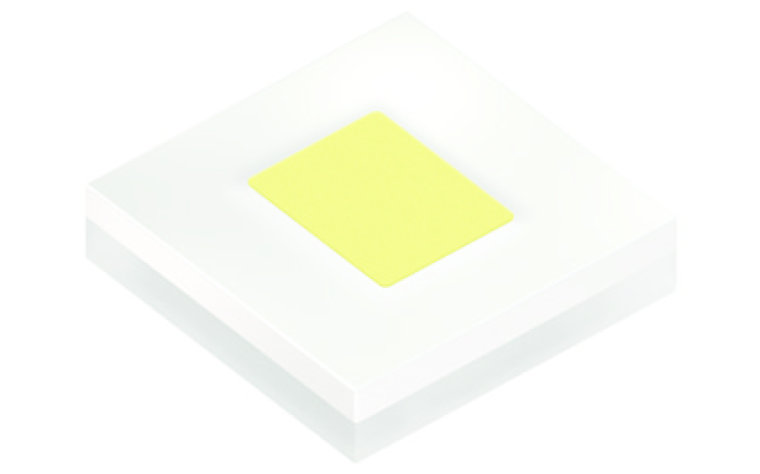

Despite smaller contact pad size, the CSLPM1.TG (seen below left) has almost the same thermal resistance as the Q8WP and gives it the same overcurrent capability according to the datasheet graphs.

The benefit will be that it can now fit on an XP-size board easily just like the black flat.

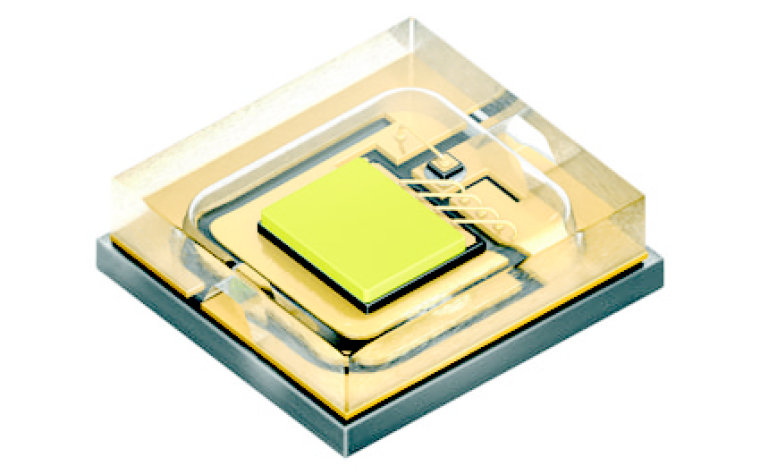

It is unclear how having the new only-surface-emitting design will affect the intensity, it has no weird polar distribution from side LES like the Q8WP does, The die area is 0.08mm^2 larger, and the flux for the minimum bin is 400 now instead of 355.

With similar or more lumens, and no side LES, but larger die area, I would expect similar cd/mm^2 than the Q8WP, which is already extremely high 245cd/mm^2.

The specs from the website (in this post) show the Q8WP as higher flux because the highest bin goes up to 710lm while the new LED only goes to 630.

But since we seem to never get the highest bin anyway when buying our LEDs this likely does not matter as much as the minimum bin does.

Based on this, there are two LEDs which are important to test as soon as they are available to buy:

OSRAM OSTAR® Projection Compact, KW CSLNM1.TG

OSRAM OSTAR® Projection Compact, KW CSLPM1.TG