I did not test the slicing of that exact led (I could not find my stash) but I did try it on the 5000K 90CRI LH351C, the SPHWHTL3D50GE4RTMF to be exact, that maukka did extensive testing on (link). The effect of slicing this led should be similar to slicing the 5000K 90CRI LH351D though.

I now did my homework and did do the tint measurements before the slicing too.

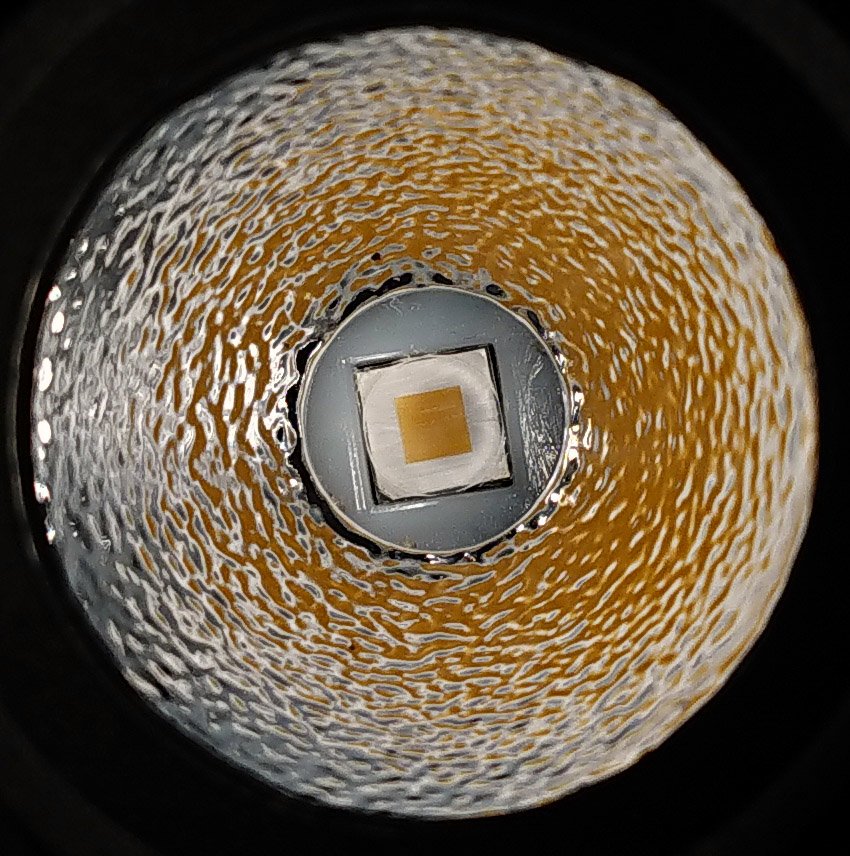

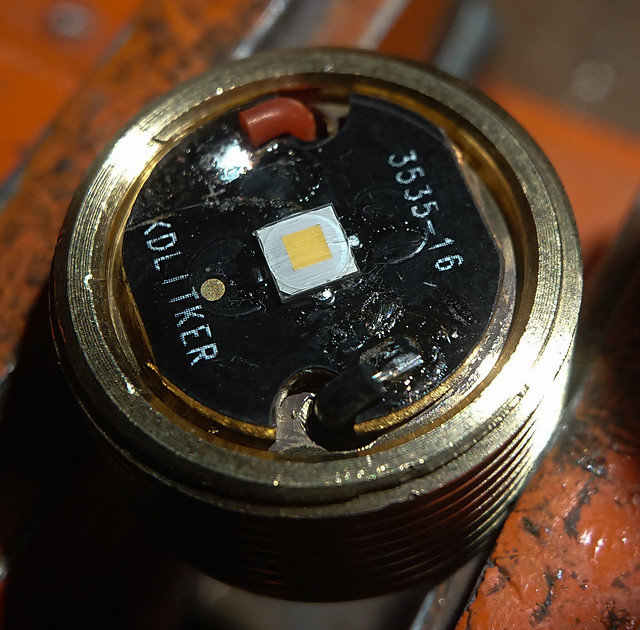

I modded a Utorch S2+ clone with the SPHWHTL3D50GE4RTMF, and with a 2.8 A biscotti driver. All tint measurement were done in the hotspot (which is the most relevant part of the beam that you want data of).

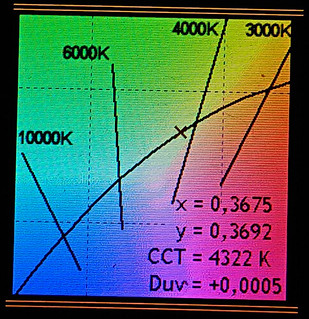

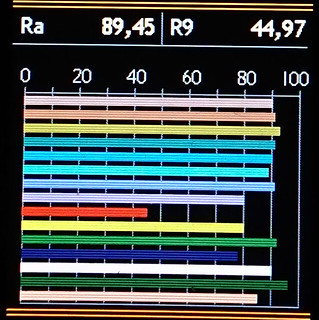

First with intact led at 2.75A

Then I sliced the led, not the cleanest slice but I’m beginning to suspect that how close you are to the die has more impact on the led behaviour than how even your surface is.

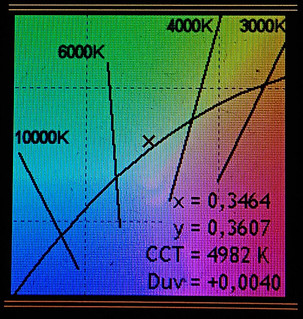

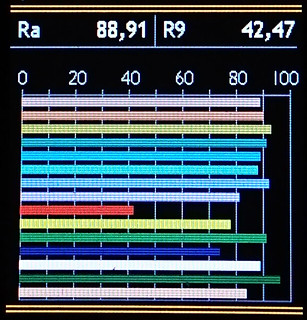

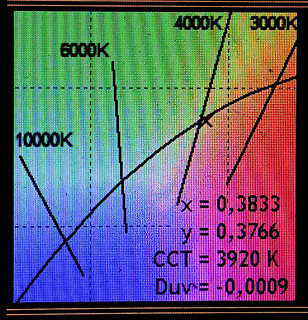

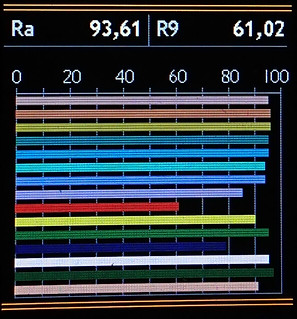

Now with sliced led at 2.75A

Same sliced led at 20mA (not from biscotti driver but by connecting the flashlight head to a led tester, so not PWM-ed)

Now apart from the colour data, that show a very similar effect as the slicing of the 4000K version (lower colour temperature, preservation of CRI, closer to the BBL), the beam looks like a very good neutral tint: no green, not too yellow, not too rosy, I like to call good coloured neutral tints “brownish”. Here is a beam shot for an impression, all lights are at fairly low level, the sliced LH351C beam is in between a (led=intact) LH351D 4000K 90 CRI beam (Q8), and a 219B 4500K R9080 (ROT66, beam from TIR optic).

(the Q8 is a bit too green, the ROT66 is a bit too red, the picture shows less tint difference than reality)

I also measured the light loss from the slicing of the led and I now got –19%, so that is also similar to slicing the other Samsung led.

One thing not mentioned before: slicing causes better tint and less light, but of course it also decreases the spot size of your beam and increases throw (did not measure by how much, my educated guess is 35–40). This can be relevant to what flashlight you are building.