Super kewl project ![]()

Just on a side note I think the reflector is the same as I used in the Old Lumens tribute torch which has an XHP70 led in it.

I’ll try and track Wayne down.djozz. ![]()

If you dont get one Glenn I’ll have to leave town. :person_facepalming:

Thanks pp. Yep I’m enjoying this one, so far. ![]()

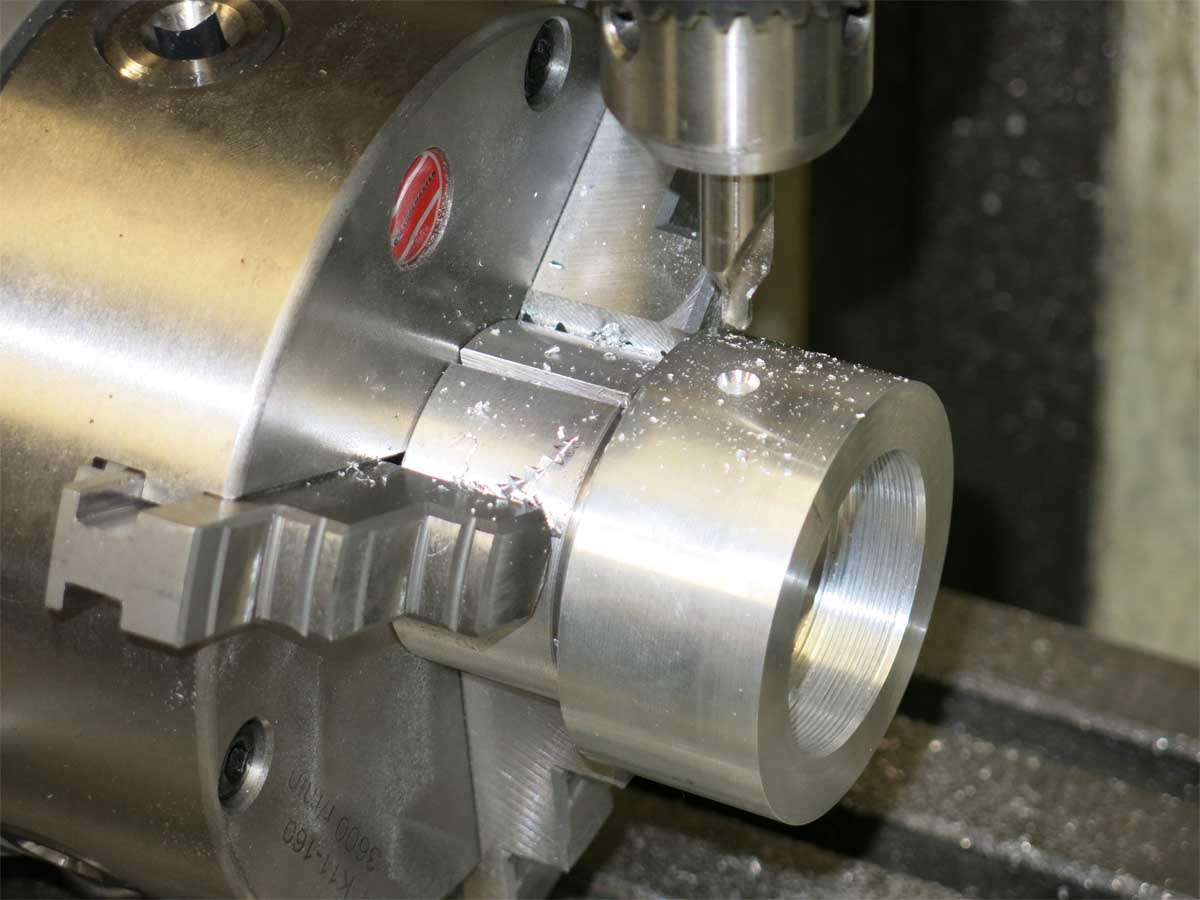

The driver retainer ring was made next. This ring is broad as it will also be the earth contact from the battery carrier to the driver.

The battery tube material ideally would be 2’’ diameter. Unfortunately we dont have this size in Australia, 50mm being the closest. The other option was to machine the tube from solid which I did not want to do.

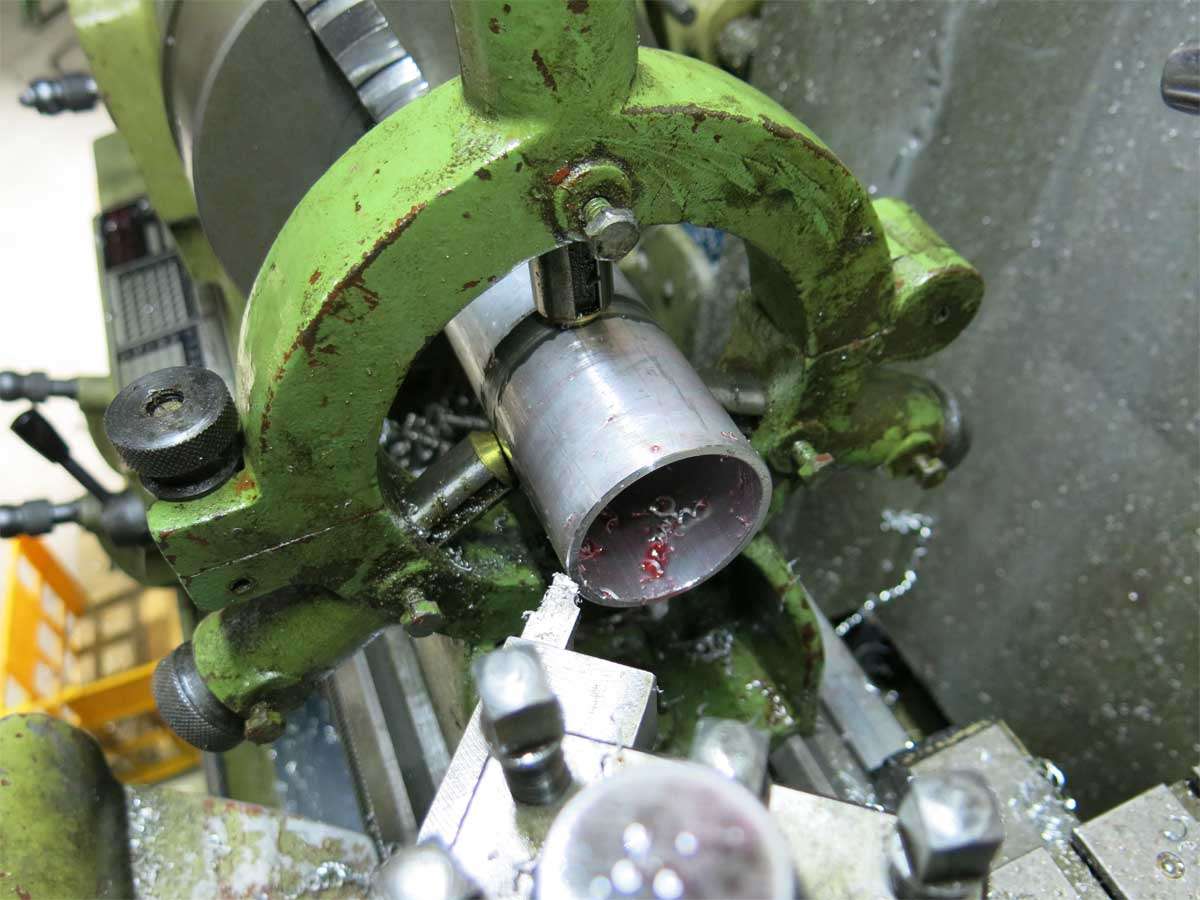

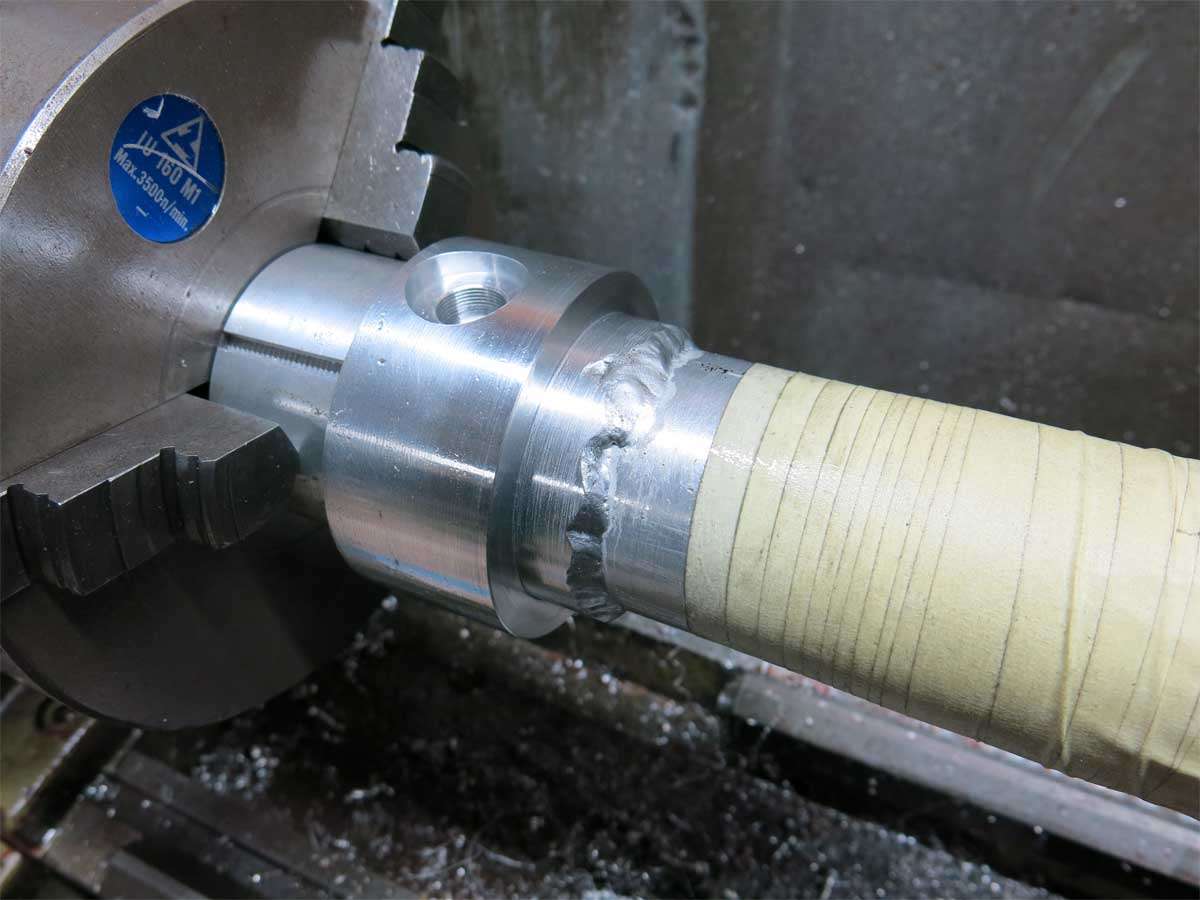

I’m a total novice when it comes to welding aluminium so this should give a few out there a good chuckle. I decided to build up one end (which is now both ends, not shown here) with weld and machine this down to about a mm more than required at this stage. The end welded here will be threaded for the standard tailcap.

I have no idea if I can make this work yet but will persevere until it doesn’t or does work.

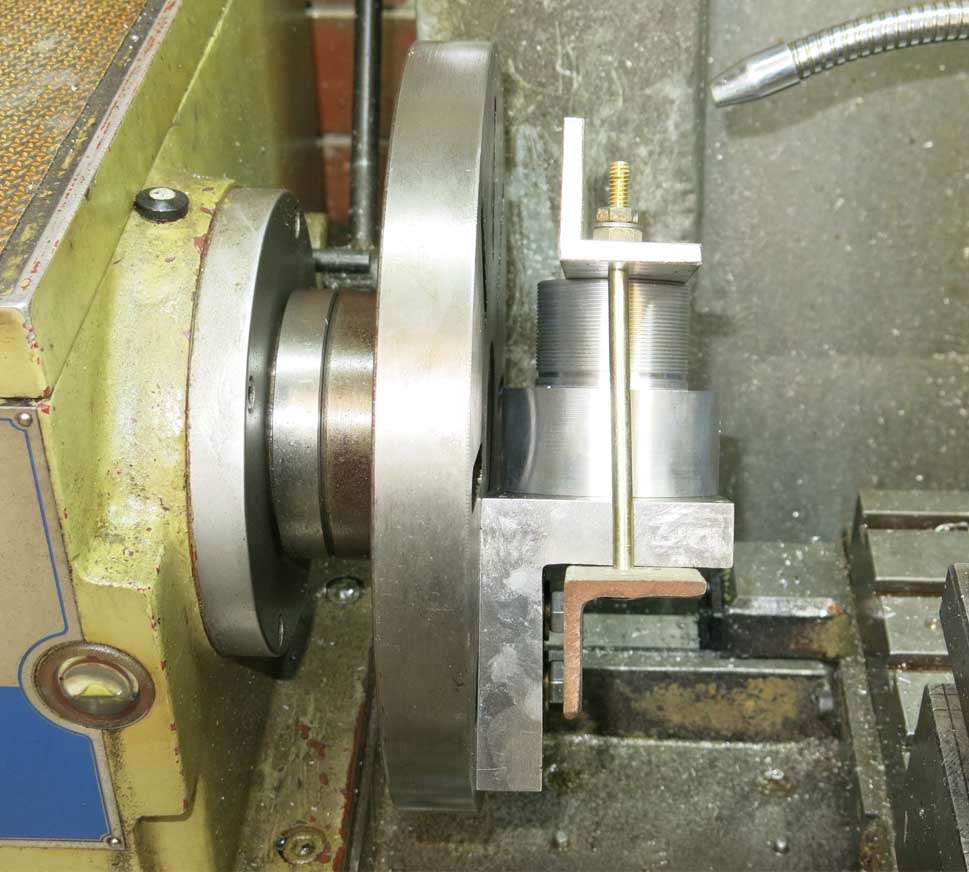

The battery tube was then machined to length. A fixed steady rest was used to stop the battery tube from getting ripped out of the chuck from the side load the cutting tool applies to the metal as it is cut.

Back to the driver retainer.

I wanted to use a Convoy S2+ metal switch button. The pill was set up in the mill and a hole drilled so this could be set up square in the lathe for threading.

Unfortunately the setting up of the pill in the four jaw chuck did not go well and damage to the battery tube thread resulted. As the length on this part was critical a lot of messing around fixing it was required.

The decision was made to purchase a small angle plate and bolt this to the lathe face plate. Its the large angle at the bottom.

The pill was then set up square and clamped to the angle plate with angles used as a clamp.

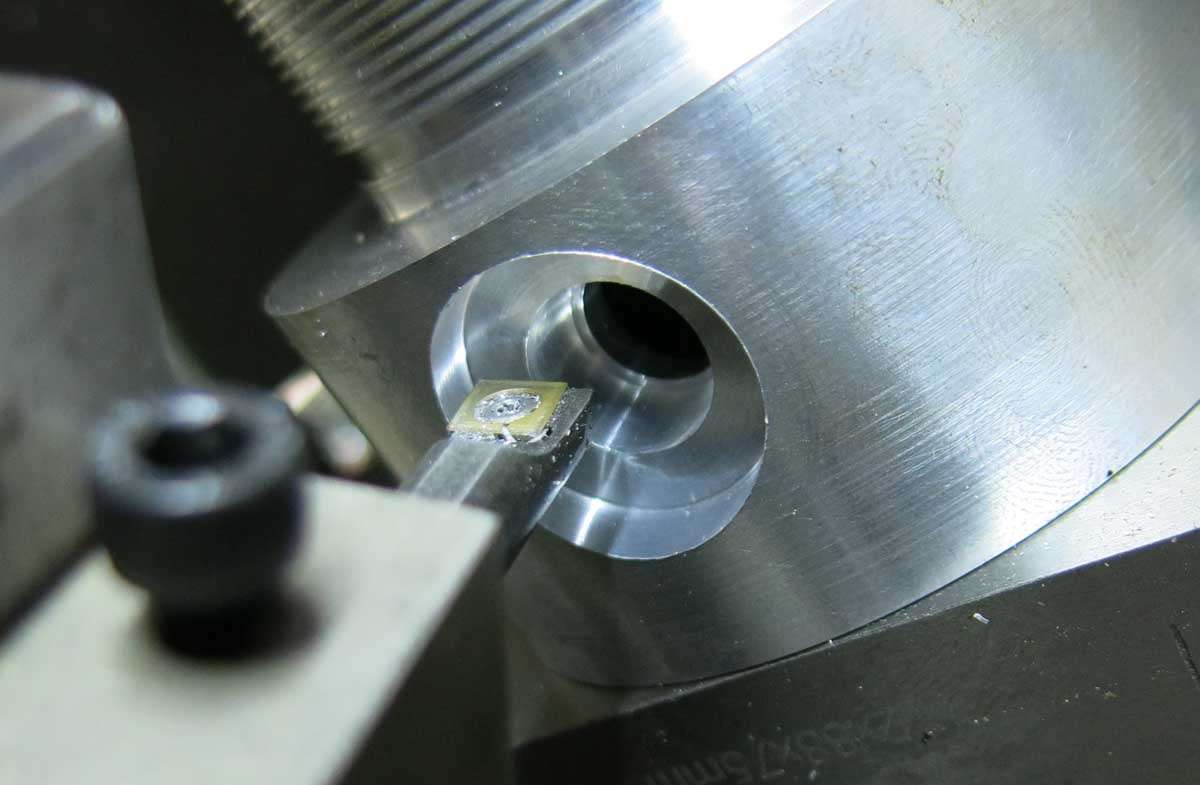

The hole for the thread was machined to the correct diameter and a recess machined for clearance around the switch. The thread for the metal switch is 12.4mm in diameter. Just less than half an inch.

The thread was cut by turning the face plate by hand instead of running the lathe powered up.

And we end up with this. Looking from the inside. I love using items designed by members here on the forum. and this is the switch mount.

https://oshpark.com/shared_projects/jlidNxF6

It can be found in Rufusbducks thread.

And the switch button from the outside.

One last picture showing the switch, switch pad and S2+ metal switch button ass.

Welding aluminium I understand is difficult, well done, it looks like the plan worked!

Nice progress ![]()

How fast did you spin the face plate set up? And how far out of balance was it?

Nice work btw. I hardly ever weld and it always turns out like cocky s#1t so your aluminium looks fine to me.

I’ll find out if the plan worked when l knurl the tube. At the moment I need to make a boring bar to bore the tube as mine are to small and the one at work flexed the tube to much.

A mandrel to hold the tube when it gets knurled will have to be made to hold it rigid. Hopefully all that will work. If not there will be a lot more work. ![]()

It was way out of balance. I’d guess I could only get about a 100 RPM before the whole lathe shook to much for comfort.

The battery tube has been a source of frustration and a lot of learning has happening.

The original battery tube in the above pictures has been tossed in the bin. It needed enlarging slightly on the inside diameter to fit the battery carriers. I thought the easiest way to do this would be with a hone as I did not have a boring bar that would do this job.

I was wrong as the hone wore itself out without really doing a lot to the inside diameter.

I decided to then make a boring bar and grind a piece of tool steel to do the cutting. When machining the inside diameter with the new boring bar the tool steel would lose its edge without really doing any cutting. It took far to long for me to realise that the cutting edge was being dulled from the hone stone that must have embedded itself in the aluminium.

The trash can came beckoning.

A new battery tube was started from scratch. The below picture is of the home made boring bar made from a piece of 1’’ round 1020 bar.

The length of the cut was about 165mm.

And at last we had success.

The weld was then machined down so the switch area of the head would screw on.

And at last.

The pill section was placed in the chuck to hold the battery tube so the profile could be machined.

The thread for the tailcap was then machined and the tube surface turned flat. There was a slight mistake by me setting the levers for the thread pitch. Istead of the original 1.25mm pitch it is 1mm pitch which means the standard tailcap will not be used.

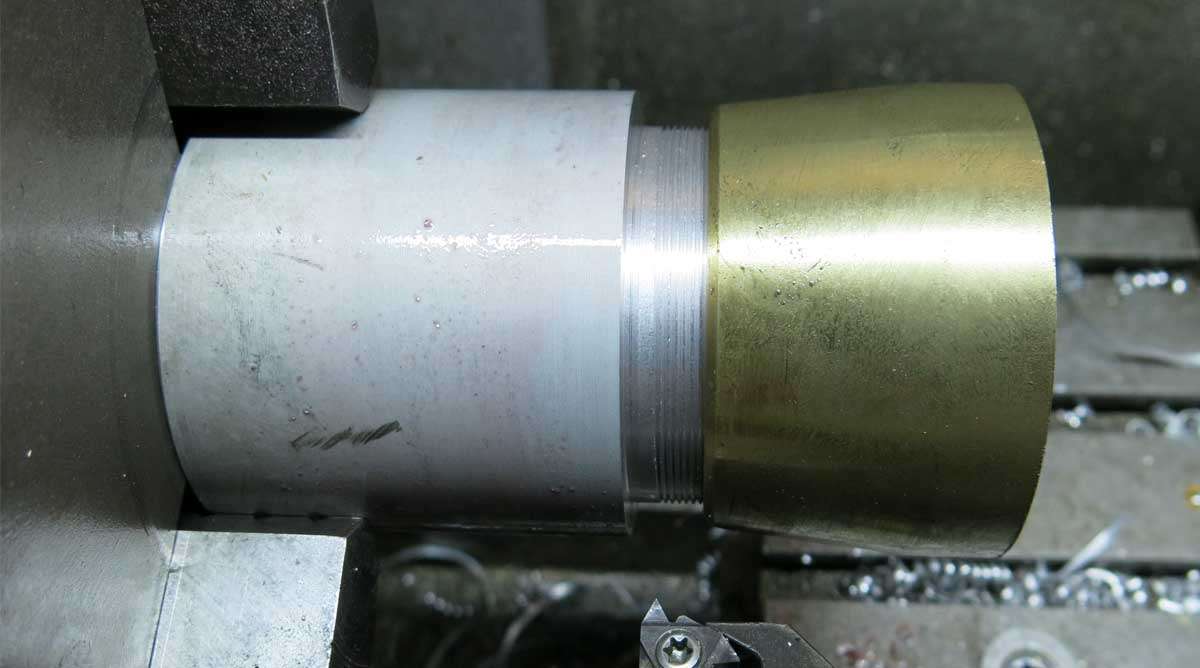

The tailcap is made from a piece of 63mm diameter brass bar.

The inside of the tailcap was machined ready for threading.

A neat thread is always welcome.

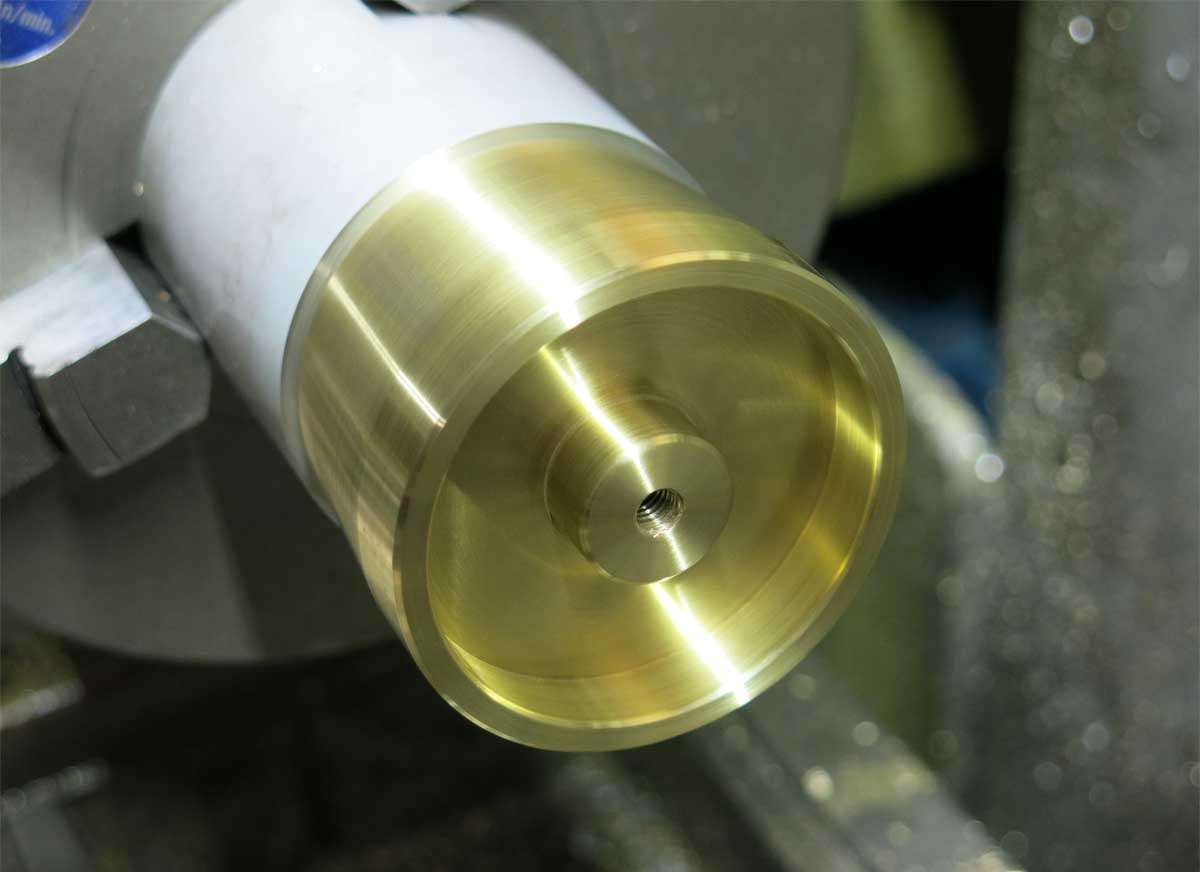

The power hacksaw was again put to use.

A mandrel was turned up to hold the tailcap to allow the end to be machined up.

Poor you, doing all that extra stuff! All for that classic ST90! Wayne will be proud though. ![]()

Wayne may have finished modding this light months ago. ![]()

Great work so far!!!

Very cool! ![]() Nice idea, save, comeback with the brass tail cap!

Nice idea, save, comeback with the brass tail cap! ![]()

The extra weight of the brass may balance the torch a little better as the head really is built like a tank.

Yep it is a Beast! Is the aluminum going to be anodized?

If I did not have a full time job and a spare shed I’d love to get into Anodising but at the moment unfortunately no. Acid here is also on the banned list of items we can purchase.

Some Rare Elektro Lumen lights…

Nobody anodizes down-under?

I’ll leave it up to the owner of the torch if he wants to get it anodised by a third party.

I wont be doing anything to the stock components so the torch can be converted easily back to standard.

I’m a bit of an old sentimentalist at heart. ![]()

Lol, how much of the original light will be used in this?

The less the better for us, we like watching ![]()

Great job ![]()

Appreciate the comment. ![]()

The head assembly is the only used item from the original torch.

Theres not a lot left to do. The tailcap to finish off and then assembly. Just need time.

There was a 12 hour race on idiot box yesterday that got in the way. ![]()

I missed this one awesome project!

The hacksaw looks like its steam powered ![]()

I was at the Bathurst 12 hours yesterday i watched about 6 hours from half way. It was so damn hot. I went for a walk to see if i could find Mick Doohan but could find him.