I do not know how he knows, well, actually Sofirn folks tend to talk all the time about their new projects ![]()

But yes, there will be a C01 pro, but it may get a different name in the end. No idea if it will get a TIR optic or a reflector, but the led will very probably be SST-20 95CRI (4000K and/or 3000K), and there will be two or three simple modes (it being a twisty). I have not seen a design yet so I would not expect this light within the next few months.

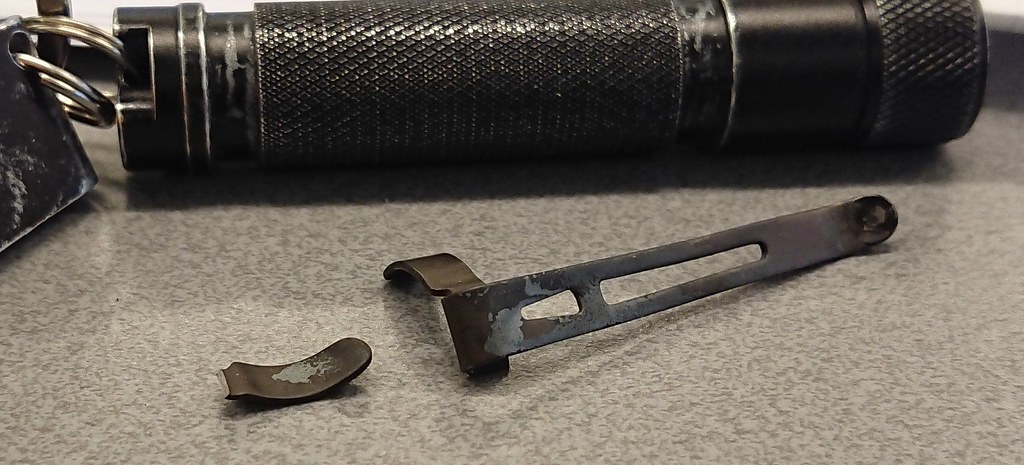

Hmm, I was very proud to have succesfully hardened my C01 clip, but I should have known that the rough way I did that was an insult to the noble art of hardening. ![]() Next iteration (I have one more bendy clip leftover) will be waiting 1 second longer before quenching under the tap.

Next iteration (I have one more bendy clip leftover) will be waiting 1 second longer before quenching under the tap.

crap haha. If you temper it after the hardening it should be better. and tempering doesnt take away any of the hardness if im correct. It just realines the carbon atoms.

Will try ![]()

Yes, quench hot and fast - you want a 100% transformation from austenite to martensite, and slow cooling will result in retained austenite or pearlite at room temperature. The tempering will lower the hardness, but if done right not below the properties of a proper spring. Not knowing the steel, I would try tempering at 500 - 600 degrees Farenheit, or perhaps as much as your oven can reach. Let it cool slowly after reaching full temperature. The structure will still be martensitic, but it will relax the carbon and iron matrix adding ductility, as in making it less brittle, which is your problem after the quench.

Holy crap! I came here for flashlights, dammit, not to learn about hardening/annealing/tempering steel!! ![]()

Please, Sofirn, only Two modes, 10/15 % — 100 %. ![]()

Is that an assumption, that it was the heating process?

I think I recall someone suggested earlier that the sub-contractor’s sub-contractor had substituted the wrong metal to make the clips?

Sofirn needs to somehow extricate their company from the usual corner-cutting approach.

Sofirn needs to decide to work, as the saying goes, in the early years of a better nation — in which no party in the chain of supply is trusted without QA and QC being done routinely.

Since a couple of people have been able to heat treat their clips …. it stands to reason it was the heat treat that was woefully lacking. Whether is was wrong or did not happen… who knows.

But from the look of djozz’s clip that was bent… it looks like heat the treat process was skipped altogether by the supplier.

My reasoning differs, I can’t rule out the possibility the sub-subcontractor supplied the wrong alloy.

You can heat treat any alloy and get some improvement, but you can’t get the desired results from every alloy.

If their subcontractor supplied the wrong metal then they’d get an unexpected result, and leave the metal in an unanticipated condition so another heat treatment cycle would give an unwanted result. It doesn’t appear easy to undo then redo heat treatment to get it right the second time, even starting with the right steel.

http://www.engineeringenotes.com/metallurgy/steel/heat-treatment-of-spring-steels-metallurgy/26992

No, I’m not a materials scientist, I’m just reading what I can find online. As with most tech stuff, I find that it’s far more complicated than I’d have thought.

djozz, have you received any updates on when the red and blue colored versions are expected to be available? Thanks in advance.

I’m going to go out on a limb and predict…

…Not in time for Christmas.

there are 49 left in 3200k and 45 left in 5600k

I predict no red or blue until this Black batch sells out

Could very well be, either way the heat treat was:

- [1]not done at all

- [2]not done properly for the steel used

- [3]the steel was a wildcard from the supplier.

In case #3 there would be no way to heat treat it properly because the steel is not what it is supposed to be.

No matter which it was, a crappy clip was the result for some of the CO1’s.

As far as heat treating a second time or even a third. It can be done with no problem at all if the steel has not been super heated past it’s limit on the first heat treat & ‘burned’ the Carbon out of it. So… if you ’miss it’ on the first go around, try again.

Tempering after heat treat is very important…. otherwise you just have a hard, brittle piece of steel. :person_facepalming:

Heat treating is a science. There are standard formulas for known steels that give optimum results if followed.

If you’ve never heard of Paul Bos (Buck Knives) & are interested in heat treating, do some reading… he was & is a master at it.

I have no update about the coloured C01’s after it was announced for “early december” which obviously has passed already.

Just received my first 2 of 4 and want to commend all parties for the hard work.

These would have remained an idea but for the passion of BLF leaders and a company like Sofirn who listens to and (more or less) delivers exactly what we want.

I’m really impressed with the quality. I’ll have to snag a couple more of these little gems for friends. I think mine will pull double duty as an EDC and a bug-out bag/emergency light.

Got mine and I’m please, thanks goes out to everyone involved in making this happen

How about a limited run of (preferably Grade 5) titanium? I can’t be the only one wanting that

Got mine and I’m please, thanks goes out to everyone involved in making this happen

How about a limited run of (preferably Grade 5) titanium? I can’t be the only one wanting that

You are actually the first to come up with that. Twisties in titanium tend to suffer from gritty threads, but I have a ITP i3 in titanium that works very well. Does Sofirn do titanium editions at all? What would be nice is if the “pro” edition is there, to have that one in titanium ![]()

I was comparing the C01 and the E01 last night. I really wish the C01 has a more narrow degree LED to give it the throw like the E01.