those separation gaps are a lot smaller than on regular XHP50.2, tricky to reflow if not done with stencil and paste and perfect placement

Major respect to Dale, always amazing mods and without a doubt the king of X6 mods in particular.

As a little bit of a tribute to DB Custom and a little bit of a one up to his daily mod I decided to class up my X6 a little and squeeze a little more out of it. Dale convinced me to start modding and helped me a ton via PM when I had no idea what I was doing and had never opened a light or used a soldering iron.

Changed from a Nickel BeCu spring with no bypass to a 20g bypassed silver BeCu spring. The silver spring was not necessary but it afforded a bit more room for the bypass and I wanted to try them out

This was one of MANY tricks I learned from Dale and have used on half a dozen lights. Flip a clear tail cap inside out and put a small hole through horizontally. Now you can use a toothpick or something and feed a nice 6mm tritium in there.

First attempt at heat treating stainless. This was done a while ago and didn’t turn out great but I do think it’s cool that it at least made it a matte finish

Dale is also a big advocate of high quality lenses so naturally this gets a UCLp AR acrylic lens . It’s doing double duty cause I needed a bit of slack to be taken up in the bezel. Also featuring the narrow Angie optic like the D4S.

And finally the trit switch all put together

Driver: MTN17-DDm

LEDs: Luxeon V 4000K

Spacer: LED4Power

Vapcell VTC5D battery

4,427lm at 0s w/ nickel BeCu tail

5,605lm at 0s w/ bypassed silver BeCu tail

Reflow oven T-962A full mod report

After using a hotplate in addition to a hot air gun for quite some time I wanted to upgrade to more professional gear

Problem is real professional small reflow ovens cost 2,000€ and up

Chinesse start at about 170€ but come with a lot of issues

I have chosen the T962 Series Model A that is a bit bigger than the 962 for 280€ shipped in EU

I bought this in EU because I doint want to have trouble with customs because its basically nowhere near having the requirements for a CE label

Even if its not the worst you can read on every spot about this oven, in my opinion this is the most severe issue to be fixed first

1. mains earth is a mess on this thing

most parts are not grounded at all, worst case is only the one screw of the socket is grounded rest of the whole case not

- removing paint on the back panel (and yes a lot hot melt glue on this oven, hope the insulation is good)

- using a proper washer with teeth to follow the safety rules for grounding (even if its a bit rusty dicovered later on PC on that Macro image)

- Now also a washer on top (a recycled one from some old gear that had seal paint)

and a bridge to gound the other parts both with safety nut not the original crap

- removing paint on the 2 main housing parts forming the top and bottom

- crimping connectors with a professional tool

- will also add here on reassembly 2 “teeth” washers

- rewiring the 2 phase switch actually to switch N and L, was before only one conductor both parallel

so now the switch lights up

and it swithes mains and L+N off (the sockets are here in Germany have not a fixed position for L)

- grounding the front drawer as the metal parts do not make proper contact a lot of grease on the mechanical parts

.

2. Replace the “stinky” tape

First you can read on all forums and blogs ect. about all those ovens

- you got to remove the masking tape, because it will burn and stink horrible

- and replacing with Kapton tape

- Then I read dont forget the hidden tape on the drawer junction ![]()

replaced with more Kapton tape

- I did a larger area of the top covered than originally

.

3. remove hot melt glue on front window

they simply used hot melt glue to fix the position then applied silicone, but seems they wanted to get production time as minimal as possible so they leave it there and assemble asap

also one thread was messey

Mod material

.

4. 13.5dBA 40mm case fan

original: SanAce 40

40x15mm, 0.11A, 8,000 RPM, 33dBA, about 15m³/h

The frame mounted to the protection cover inside the case, this also makes some recirculation

Cooltek Silent Fan 4020

40x20mm, 0.05A, 4,000 RPM, 13.5 dBA, 11.5 m³/h

2.99€ shipped with Amazon prime not 9€ Ebay

I mounted the protection frame outside to eliminate recirculation

5. Cold junction Mod and new firmware

.

6. hot air circulation fan

ordered today one that hopefully can be made fit

I am pretty sure I got to move the middle termocouple hole from the current position, but getting the termocouple mounted on same place as before or mount a smaller fan blade

PS I removed both thermocopuple tubes and placed the fan in the middle of the compartment

First taking off the top cover which was screwed down with 4 scres that were below the amulinum tape, but easy to locate

And more of the stinky masking tape

hot air oven fan 230V AC motor

open compartment with the IR tubes exposed, I measured those below the rated power, maybe replace later IR camera test will follow to see if the boards heat up evenly

fan blade made from aluminum, have simple bent it so it fits below the IR tubes and the compartment top cover

as the compartment is from thin steel, so I used a 4mm aluminum plate that I found in my used metal box, already marked the drill spots using the old mounting plate

I used 5 washers to lift the mounted fan motor enough to clear the IR tubes, holding it in place unscrewed fitted,

screwed down it was stuck on the IR tubes but as I had about 2mm distance from fan wheel to the cover

I added one more 1mm thick washer and that was enough to make it spin freely

.

7. hot air fan switch and manual override of cooling fan and IR tubes

proper holes made for them, but I might buy another switch for the fan so I can manually disable the cooling fan when IR tubes are manually on

will see if the profiles work good enough so no manual heating on the end of the cycle is needed

wiring switches with heat resistant silicone wire

drawer was modded with lifted PCBs, simply 3mm screws with fitting washers and threads cut in the PCBs

so the boards are thermally decoupled from the drawer

the bigger one got the 2 original thermal probes attached with SMD hot glue

.

8. unhappy with heating up, not enough power, hot air circulatuion unusable

I measured the heating power with 800-900W depending on filament temperature

not enough especially when the hot air circulation is on the board temperature raise is way too slow to follow the reflow profile

here I had the hot air fan only on during the soak phase the lamps on at 100% barely getting the temperature stable

then I switched it on at peak temperature and cool down

I ordered now 6 1300W tubes 10 inches long

having the tubes connected as pairs in series I get 1950W

this should be sufficient and the 10A electronic relais should handle that with no problem

P=1300W*6/4

also 12 of those holder which schould fit the compartment, I may have to add a few mm to make the tubes fit the spring loaded contacts properly

also the cool down is a bit slow I think about removing the back side slots and replace that with a steel fan protection for less resistance for the air flow

the used fan is an EBM Pabst 4656N with 230V 19W 160m³, nothing to change there to improve much in the same size

I had a look in my fan box and having on hand 120mm a 19 (same model) and 20W 230V one

as well as a 150mm 39W with 405m³

I guess I go for the big one mounted outside, just need to order a fitting fanprotection

cutting hole just with hand cutters at it in the middle of night here, tomorrow I will get the jigsaw

the metal quality is very bad sometime the steel simply broke when bending it outside to cut next part

also the feet need to be replaced as they smear black stuff when moved without lifting completely

bite out all the old fan slots

Used a saw to remove as close to the new smaller marking then a Multitool to grind the rst away

also drilled holes for new fan

taped the inside insulation to prevent air from blowing inside it, now all air should go into the PCB compartment

threads cut

FAN!

.

9. installing new heating tubes, I have chosen replaceable with holders, so if one blows its easy to replace

- first I searched for some 6-10mm thich aluminum plate, as the 10 inch tubes with the 30mm holders are 6mm to short and I need some spring pressure

- sawing the piece in half and adding threads

- removing old tubes and hey they really got Kapton tape in their factory but dont use it where the cheap masking tape is used

- Of course after I put it together I realized I sawed and added holes for mounting all mirrored ![]()

so I had to rotate all holdery by 180° of course 12 new holes and threads

and I am an idiot didnt thing about the wires, of course the top part closes leaving only a circle where old tubes were

- so now taking that thing completely apart and drilling holes througn where the holders are and for electrical safety I used a cone drill bit to remove all sharp edges

- now also the oppotrunity to completely seal off that fans air tunnel so the air moved through the chamber not inside the top housing

- I decided for more safety and electrical wiring to use this time not 230V for the heater wired to the front manual switch

so I looked up how the heaters Triac control voltage is wired on the board

it is coming from the MCU then goes 2 times through an inverter which switches ground

as I do not plan to blow that inverter I simply added a diode between its output and my manual switched ground

- 2kW tubes are different type more like conventional red light tubes but driven at 115/230V 2 in series

now the compartment got a nice red glow during heating where the original heat elements were barely visible

.

Final summary:

- Hot air oven out of the Box

electrical safety is absolutely noneexistent whole case was not grounded, just one screw ![]()

stinky tape which will smell horible if not removed

sucks for my understanding what I expect from a good product

gets leaded stuff done with enough heat

but can cook or leave stuff unmolten

- new Firmware and cold junction compensation

better, but the real board temperature is way off what is measured from the sensos between the IR tubes

option to calibrate the temperature probes

still measuring air temperature on a IR oven is total wrong aproach

- Probes moved to some dummy boards

while the temperature looked good measuring the air temperature now the truth is measured, pretty disappointing

- hot air circulation fails

now it shows its waekness, 800-900W heating power is not enough not even the claimed 1500W

does not work anywhere close the heating profile when hot air is on

tried to have hot air fan on from beginning, but heat up was slow so turned it off

hot air fan on during soak and peak temperature on, manually heated longer than in profile overriding heat tubes

- IR tubes replaced with 2kW tubes, bigger fan and taped the fans airflow airtight

now its working like expected, air circulation during whole reflow

I can run the hot air fan all the time

@contactr, nice build.

How much power is it consuming?

Do you have a power supply and thick leads capable of measuring voltage as well as current?

Also, seems like there is room for improvement still with my springs with very high drain cells. Will make some tweaks for the 3rd revision.

Finally, would you think about doing this mod using XP-L2s?

At that point, the sky would be the limit ![]()

19.9A without topping the battery off again. I don’t have a good power supply. Not a fan of XP-L2’s my snobbery will not allow me to use them.

C, I’m flattered! Good work!

Lexel, holy smoke man that is over the top extensive work to make it right, kudo’s to your instincts and perseverance, what a job!

A look at the colors of my sons room with the tint adjusted Quad X6…

battery problem not solved yet

open for advise

By the way, I’ve recently learned that tritium vials are weakest on the ends where the CO2 laser cut them and sealed the tritium inside. So if you have to push one use a flat ended helper that closely matches the diameter of the vial, a pointed toothpick can rupture the end and release the tritium effectively killing the trit. This from the company in Switzerland that has been making them for 50 years. ![]()

Today i try to build a quad Nichia 219b-v1 9080 4500k with a convoy C8, the kiriba-ru head and led4power driver and mpcb.

Driver was almost all solder except 3 wires that have a 3pin conector. First of all cut the wires before solder to the driver (mistake).

Later I’ve noticed that the 3 pin conector it does not enter through the hole and that it must have been put in before welding it… Later i desolder the wires and try to solder the driver to the retaining ring… I have not been able to weld them ![]()

Probably this kit goes to the want to sell section soon. Proably its better for me make simple builds, only solder postive and negative wire ![]()

If you have a needle or very fine screwdriver or tweezer you can remove the wires from the plastic connector and reinsert them on top after feeding through hole. It has a barb like a fishing hook

Put a sliced and diced 3V 50.2 in an old style C8 with a copper pill, the tube is bored to accept a 20700A Sanyo cell, Turbo shows 4320 lumens at start in my calibrated box. Pretty cool!

@alberto:

You need a soldering iron with a large, flat tip, high wattage and, if possible, a tip with integrated heating element to solder the driver to the pill reliably.

I made probably one of the smallest / lightest 18350 flashlights with built-in charging :)

Skilhunt M200 + Astrolux S43 18350 tube.

From left to right: Skilhunt M200, Jaxman E2L, Astrolux S43 (with S42S body and bezel)

I made a 18650 S2+ triple SST20 FET driver, with a*18500* Jaxman tube ![]()

I know this isn’t new, but I postponed this mod for at least 2 years, so I’m quite proud to have FINALLY took the time t do it ![]()

From left to right :

- Convoy S2 triple with 18650 tube

- Convoy S2+ triple with *18500*tube and 18650 battery

- Emisar D4 18650

- Convoy S2+ 18350 with tube

Comparison pic between how far the pill screws down in the head. I used an S2 pill in the S2+ head (S2 pill is like 5mm shorter than S2+ one) and grinded some of the threads to allow it to screw farther. There’s no edge on the top of the pille either, it’s filed flat with a wet 1000 grit finish to get good thermal contact.

I used an BLF FET driver and it heats as fast as my D4… pulls around 13A from a 30Q battery.

Nice job X3. I did it by chopping off the top of the original pill in two pieces and soldering the ledboard on the now open end. So I had no shelf for soldering the ledboard onto but the edges are so fat, almost under the leds, that it is thermally still very sound.

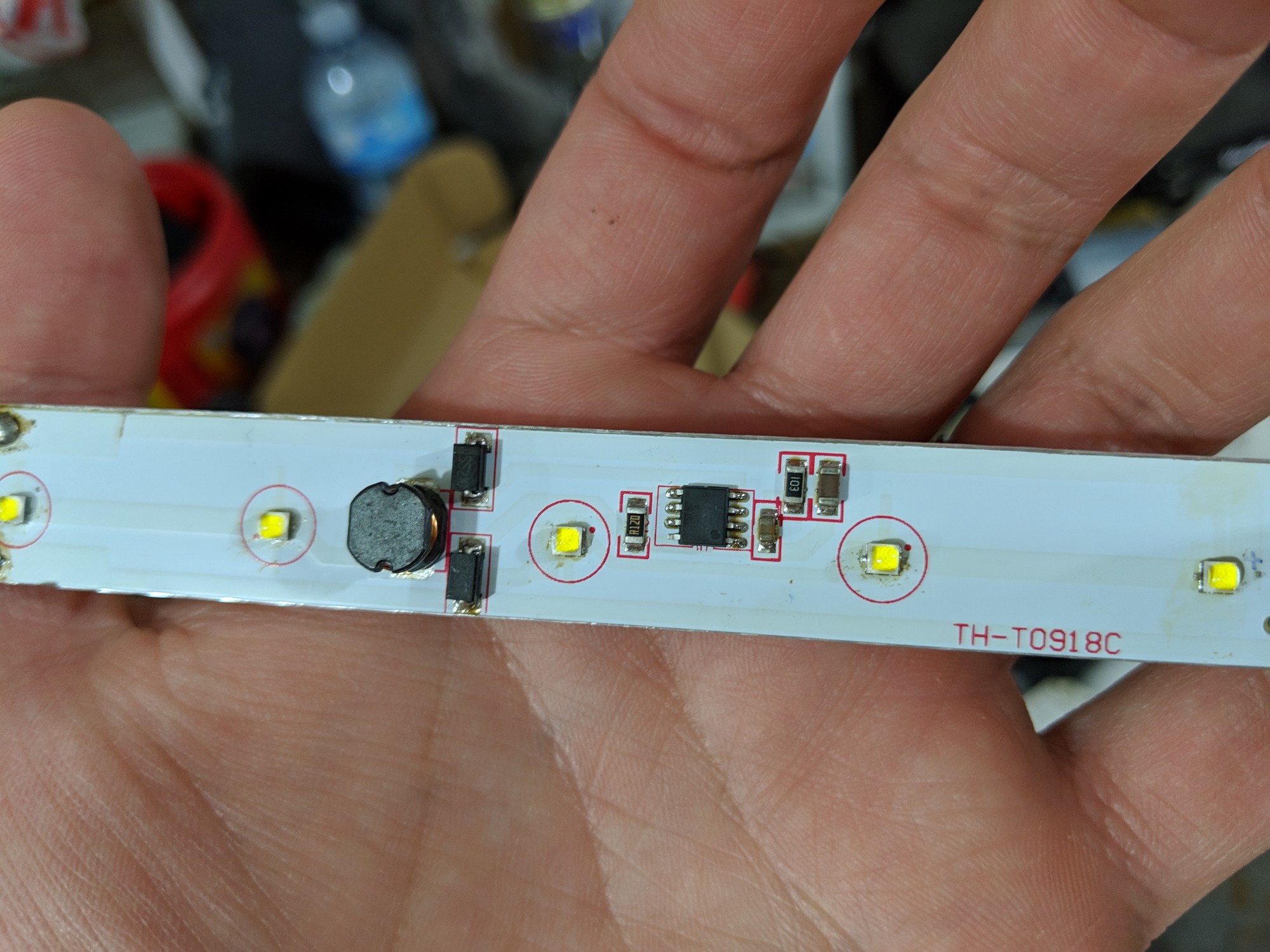

Modified my cheap “18 watt” 6-LED light bar that I put on my mower for late-night mowing (or snow removal).

Swapped out the cool white XB-D LEDs for 5000K high-bin XB-H ones (XB-H is a XP-G2 on a 2.45x2.45mm substrate) Despite it being a 5 year old LED, I think it’s the newest and brightest for that footprint. I also swapped the R180 sense resistor for an R120 for perhaps 50% more current. Hopefully it can handle that.

Before

After

I took my Jaxman Z1 and put a 22MM-7135-DRV-AW with 13 7135s...

I need to replace the LED and remove a couple 7135s now.

I also took my dead EagTac D25C Ti and replaced the driver with a moonlight special. I went with 6x 7135s, and "Moonlight--->2%-->33%-->100%" as the mode order. I treat the 100% as a Turbo, and the 33% as a high mode, and the two are actually pretty close in brightness off my 650mAh Olight RCR123A. I also replaced the rear switch with a Omtem 1288 small reverse-clicky for convenient mode changes. No twisting for me.

This had previously been equipped with a Mtn-17DD fet driver, which was single-mode 100%. The driver was dead when I got it. I'm not sure what the switch was, but in testing it felt like a reverse-clicky with crappy functionality, but it may also have been forward. I just couldn't get it to cycle modes at all with that switch. It also came to me with XPL-HI V2 1A, which I like a lot. In such a small reflector, it kind of needs the HI in my opinion. The reflector also has a very slight OP texture.

The spring on my Moonlight Special driver was very stiff and too long for the host, and I ran into issues. I didn't have a good replacement (a very short brass button would have been ideal), especially with the driver being two-sided. So I stuffed it farther down into the pill instead of using the press-fit brass ring, and soldered it to the sides of the pill. It works great now, and I'm never gonna swap that driver anyway unless Zebralight starts selling stand-alone drivers as parts. I'm really happy with it now, as I'd started carrying my Olight S1 as a "backup" EDC to my normal 18650-rotation, and while this is larger (and comically close in size to my SC62), I can't resist the nerd-metal aspect of having a Titanium carry.

Modified BLF KRONOS Special Copper X6….21700 tube

.

. Triple 3v 50.2 K2 1D 6200k

.

. Slight tweaking needed…. optics SUCK! ![]()

Is that melted optics? If so never seen such a thing