Sorry to dissapoint. But i just wiped the crud off the phone lens

![]()

Its finally done.

Beamshot .

Beside Acebeam K40m

Opened up

Recap 4 x 21700 Xhp70.2+L6 smooth reflector+ Lexel ta Driver with Bistro

Thanks 4 watching

![]() Very nice build! That will take some time to warm up, even with a 70.2. Is the led on a 20mm board? Any idea what current it draws?

Very nice build! That will take some time to warm up, even with a 70.2. Is the led on a 20mm board? Any idea what current it draws?

The beam looks impressive!

20mm board from kd. no idea of current I was hoping 7 or 8 amps,

I don’t think heat should be a problem,

Nice ![]()

Nice ![]() :+1:

:+1:

Must be a good light for camping. Solid chunk of ali with good battery life. Nice.

That looks amazing. ![]()

ok charged the batts 11.3 amps when fresh,so should be good for roughly 7000 lumens may try some heavier wires to the led and see if I gain any thing

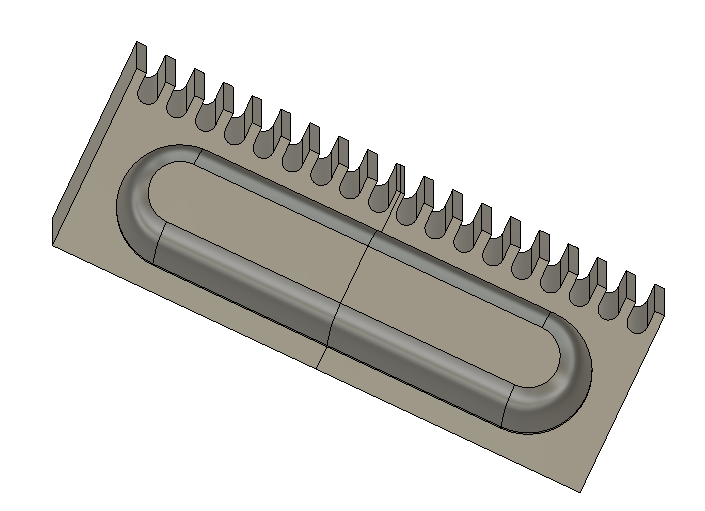

I have all ways wanted to do a lightbar, so thought I would knock up a prototype using

xhp50.2 12v 5000k

C8 reflectors

Lexan lens

3amp drivers was going to run 2 x 3a but dropped back to only 1. from Russia …

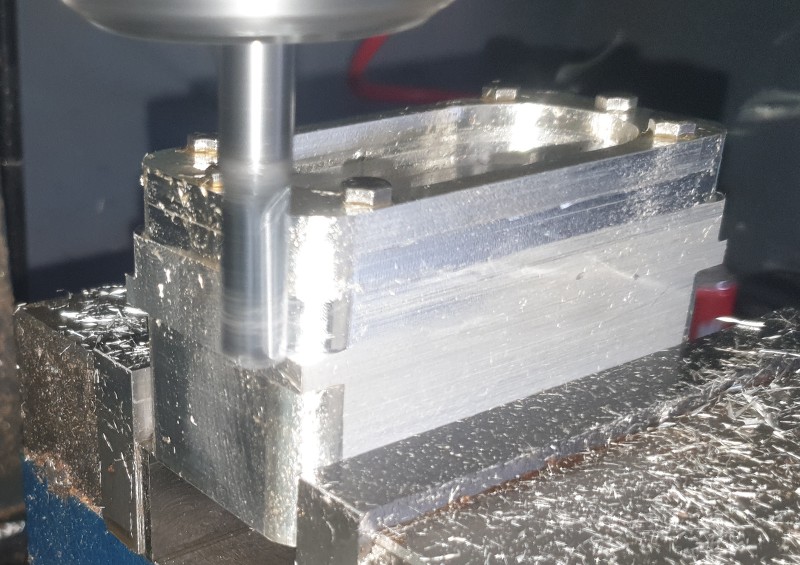

roughing out the alloy

not quite enough hardware for all the holes,

radiusing the corners

pocket for driver

assembled light

cheap ebay heatsink for the driver on back

not dark yet

relatively happy with spread / light output

nearly 3a with the car running 14v

so guessing 5000 odd lumens .

wondering if I should run the leds at this level or at 3a each,

now to make one with 10 reflectors that may take a while

You could run 3 amps each if it was cooling satisfactorily. Looks good by the way. Have your flat here still. Not sure how your going to get it.

Cheap as well. Will only cost you two of these lights. ![]()

Hellzyeah! That looks like a sweet build. Did you protect the driver from auto voltage spikes somehow?

The beam looks good.

How did you get the neat arc shape with the mill?

Still owe you for the leds among other things ,mrs dnf

wondering if I should just make them as pairs?

pp. Iam using fusion 360.after drawing your part you then choose the basic process that you want

and it will make the tool paths for you.just hope you enter the right feed rates depths ect

I think you may have been referring to the roughing pic ?

the mill just happened to be ramping down as it went around the bend

the driver pocket was done with adaptive clearing.

the main hole finished with 3d contour about a 3mm stepdown using a 10mm ball mill

the lens cut with a 6mm flat end mill.

should start a machining blooper thread for my stuff ups

PP .the driver is supposedly good to 27v input, without the car running it only drew 1.9 a seems to like a bit of voltage.

a bit of 65 mm should allow for some heat sinking and more screws for the front face

definitely dwarfs the 50mm square.

my thoughts this morning is to go in lots of four…

something like this,

drivers in the base and similar finning down the back

Stop talking Chinese and speak English so we can understand what your talking about. ![]()

Oh, so it is automated. I just didn’t notice any steppers on this rig -

From my understanding car voltage spikes can rise above 27v but those are usually in extreme cases like starting the engine. I’m not much of an expert so I don’t know how to clamp the volts. Nor do I know how pertinent it is???

perhaps something like this may be the go

updated pic

I don’t know about the spike killer but I’m green with envy over the mill ![]()