I think D2 is just a good budget steel that if heat treated properly will hold a good edge for a while and take a beating.

source: https://www.bladehq.com/cat—Best-Knife-Steel-Guide—3368

I think D2 is just a good budget steel that if heat treated properly will hold a good edge for a while and take a beating.

source: https://www.bladehq.com/cat—Best-Knife-Steel-Guide—3368

Without having experience with those 2 knives, I cant say for sure. Too many variables.

The heat treat can be very different on any steel and that’s if you know for certain that you got what you paid for. The same steel at a different Rockwell performs differently. Very few tests, other then use to confirm. One pro to buying from a named company is consistency and knowing what you got.

D2 is less stainless than M390. M390 should hold an edge longer.

Does anyone NEED super steel for edc? I’d say rarely. What are you cutting and how often? Carpet?

How often do you want to sharpen? Are you good at it? Super steels can be more difficult to sharpen.

I have knives in D2 (Mini Grip) and M390(custom and ZT). Both great steels.

At my work, I may cut rope, boxes, rubber, plastic and wood with a few other odd materials thrown in. Carpet, I have used one to cut carpet before, yes. I use it for what ever needs cut or trimmed, its a tool to me. I’m not saying I cut all that in one day but over time, I do cut alot of things, I do use it as intended.

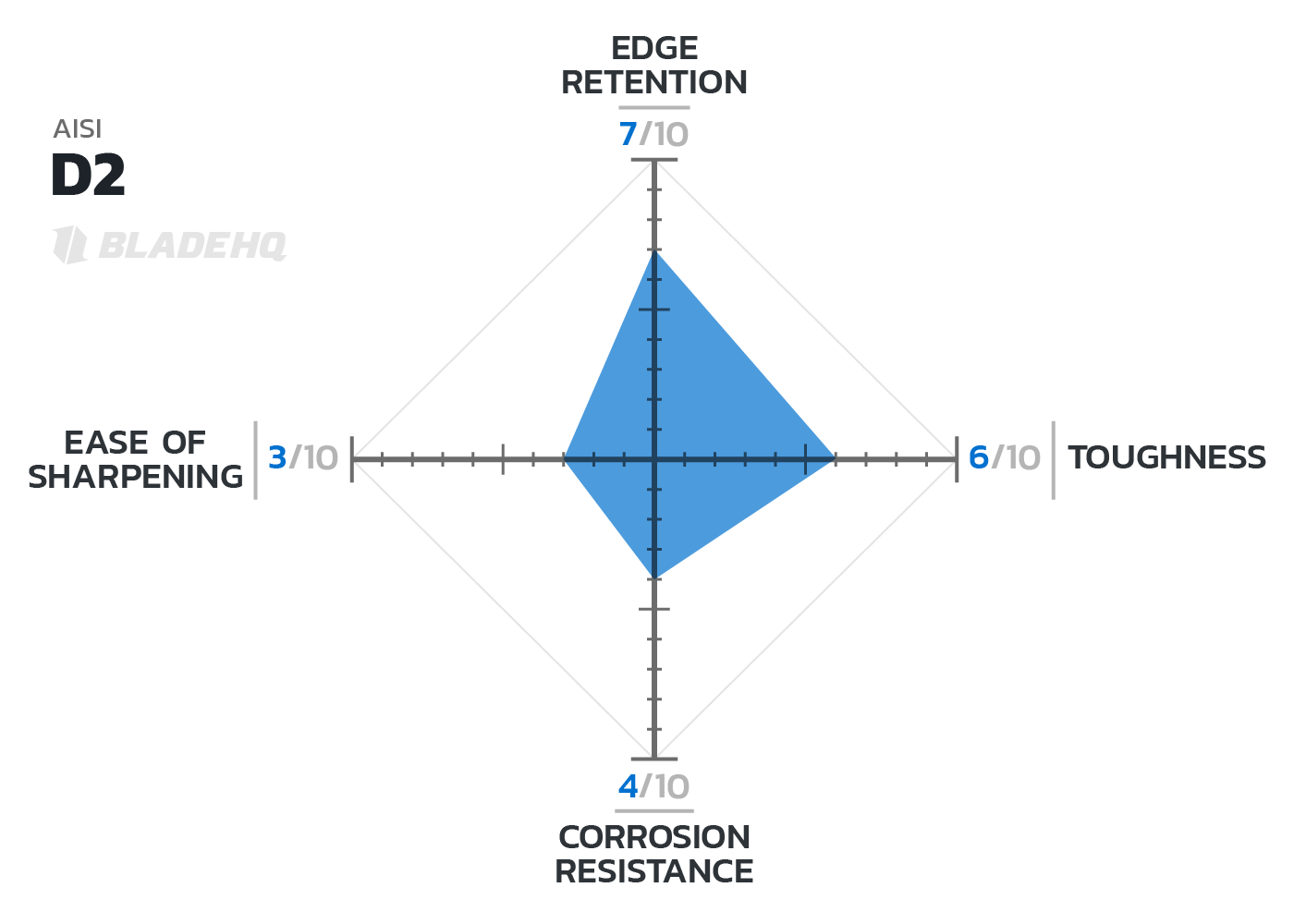

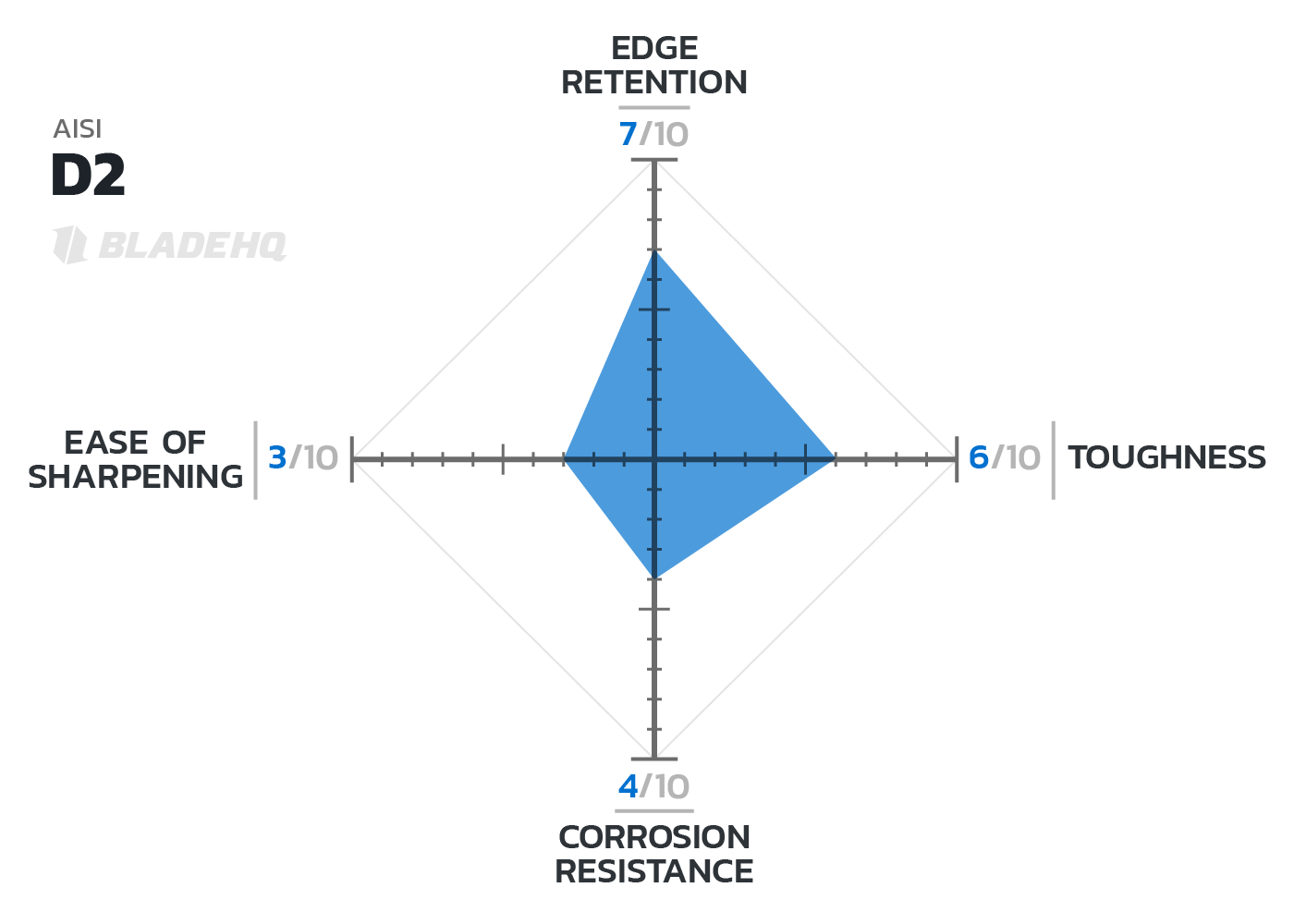

I had visited bladehq’s steel charts several times and that’s been pretty useful. But Im interested in how it does in real use like I’ll be subjecting it to.

No problem in maintaining the blade as you probably guessed I have had lots of sharpening experience over the years. I looked for a easier way than by hand and recently purchased a edge pro clone and some good quality stones. Its still quit a bit of work for scarry sharp but easier being able to hit your angles correctly ever pass.

I’m more use to steels that were sold 15 to 20 years ago like 400 series.

D2 holds an edge well but rusts easy and like most “super” steels, can chip if abused. Easy to sharpen on a sharpmaker if you are maintaining a good edge, but can take a long time to re-profile an edge that is set at the wrong bevel angle or has been damaged. I have not used M390.

I haven’t tried any of the “super steels” like M390 but I can say sharpening even S30V can be a pain sometimes - I’m also a complete novice at sharpening so take my opinion for what it’s worth. The peace of mind higher more stainless steels offer is nice, but that depends on how likely your knife will be to get wet too (saltwater fishing vs cutting material at an indoor job for example).

I’ve heard the D2 and M390 from well-reputed Chinese brands like Civivi and others is pretty good. My Elementum has held up well although it hasn’t had a ton of use to really test it.

I like D2 tool steel, and 14C28N Sandvik blades.

A reputable Chinese knife company such as Real Steel, Ruike, CJRB, Bestech, TwoSun, and Civivi have been great for me. Their D2 and Sandvik blades have been heat treated great, and that is what makes all the difference in the world.

Bob Dozier loves it for his knives.

But…there’s D2 German steel and then there’s the other shit.

It’s not as much a stainless steel as some would think, so oiling it after use is probably a good idea.

Chris

D2 is highly dependent on heat treatment. A lot of the reputation driving its popularity today is based on more expensive American knives with better heat treatments. A major criticism and source of misplaced controversy regarding Chinese D2 is that it doesn’t live up to that reputation. Well, of course it doesn’t. These are less expensive mass-production knives. In my own experience, Chinese D2 is “okay”.

On the low end with companies like Kubey, Ganzo, Petrified Fish, etc.; it’s a big win over the 8Cr13Mov we were seeing at similar prices a few years ago. Versus 8Cr13Mov, Chinese D2 has slightly worse corrosion resistance but much better edge retention. It does take a little more work to sharpen but you won’t have to do it as often.

With companies like Civivi and Bestech, you might get a little better quality but it doesn’t stand out as much. I’d much rather have 14C28N, VG-10, or N690 in the $50-100 range. Those steels can hold a very nice edge and are much more stainless. I have limited experience with M390 but apples to apples with a budget heat treatment, the M390 should be a win on both corrosion resistance and edge retention.

I agree with some points but the ontario rat 2 is a solid knife that uses D2 steel and can be found around $40-50, I personally have one in my camping gear as a beater knife hasn’t failed me yet. I consider it a “Chinese D2” though its manufactured in Taiwan the steel is more than likely sourced from mainland China.

I agree VG10 is probably the best of the bunch easier to handle and sharpen and live with all in all, I like 14C28N BUT cant seem to get it as sharp as my VG10 knives.

That’s pretty interesting that D2, VG10 to 14C28N seem to be more popular for your EDC type knife. That opens up a lot more choices for me. I like steel that gets scary sharp but I dont like to spend hours sharpening it either. Sounds like spending more money on higher grade steels may not be the best option for me.

I have seen a few china grade steels tested on youtube and most came out to be pretty accurate but you always have those that are out to cut corners.

I don’t have experience with the Rat series but their D2 models have a good reputation. I think Chinese D2 shines at that price and below. I compare it to 8Cr13Mov because at similar prices, you gain a significant increase in edge retention and only lose a little on corrosion resistance. AUS8 is similar enough to 8Cr13Mov in corrosion resistance but seems more variable in edge retention. Heat treatment and blade geometry matter a lot. Here is an interesting comparison between Ontario’s AUS8 and D2:

Of course, D2 is semi-stainless. The corrosion resistance isn’t terrible. It’s just low enough to be a problem in some environments. It can require more vigilance in keeping it clean and oiled. I own a bunch of knives in Chinese D2 and I’m carrying one right now. With basic maintenance, I’ve never had it rust on me. I just like the idiot-proof hedge of more stainless steels like 14C28N, N690, VG-10, etc. Since they are easier to sharpen and do hold a decent edge, I tend to prefer them over Chinese D2.

For stainless, I like VG-10 or N690 better than 14C28N. I put 14C28N in the same ballpark as Tangram’s Acuto 440 or a good 9Cr18Mov like you get from Civivi or Real Steel.

How do you sharpen? Stones etc?

Some blade shapes are easier to sharpen then others too.

I personally really like 12c27 and 14c28n sandvik steels. Take a nice edge and feel really tough.

If it’s real D2 it will rust if you don’t keep it clean and oiled; even blades with coatings will rust on the most important part - the edge. If you use a D2 knife on certain foods it will start to patina in seconds. I prefer steels like VG10 and S30V because they are more rust resistant.

No need to get too caught up on the exact steel - heat treatment and blade geometry are far more important than the exact type of steel.

I clean my rat d2 with mineral oil and wipe off excess, seems to help the blade slice a bit. It came with a nice oil feel out of the box.

I hope to see the trend Spyderco has been on of moving from VG10 (already a fantastic steel) to CTS-BD1N continue and be emulated by other companies. Better edge retention, still easy to sharpen and even more corrosion resistant IIRC.

D2 is a good tool steel. It is a carbon steel so it will rust (like 1095, et.al.) and heat treatment is important to get the most out of it. It’s good for general purpose and sharpens well and takes a very fine edge. I personally like good carbon steels like 1095, D2, O1 (Cold Steels Carbon V is great), and the crucible steels like CPM154 for that reason. Some of the newer steels like VG10, S30V hold an edge, take a beating, and are corrosion resistant, but wear out up my stones so I went to diamond for those. I mainly do cutlery, but some pocket knives.

I haven’t got a new knife in a few years, so most of my Spydercos are VG10, S30V, H1 or ZDP 89. No one is more cutting edge when it comes to blade steels than Spyderco and that’s great. I always enjoyed trying out the latest and greatest wonder steels but it’s really not all that important. Give me a well made, well designed knife with good ergonomics and a half way decent rust resistant steel with a good heat treatment, a thin full flat ground blade that cuts well and I’m happy.

I got a para 3 recently and I have to say im impressed. I love the frn handle, it makes it feel like the old clipit delicas. Steel is very impressive and the compression lock is the best lock imo

If you like the Para series knives check out the Spyderco smock ! its the knife that replaced my previous daily the para 2, the fit and finish along with a button compression lock the fidget factor is through the roof !

Right on, with the price increases of the Delica the Para 3 is pretty much better in every way for a very close price. Better steel (vs non-sprint run Delicas) and better locking. IIRC the Delica doesn’t have a deep-carry clip stock either.