Ok, anyone still awake in here?

Time to wake up cause I have more Graphs! Yay, exciting! :nerd_face: :party:

Spent most of the day/evening rigging up and running tests using the new iCharger based stable voltage supply. It was almost a complete success, giving me a much better idea what my voltage overhead was doing and just how this driver behaves in and out of regulation. But particularly interesting was how the 7135s behave when I assume they are just on the cusp of being in and out of regulation. Things get pretty freaky there!

-

Unfortunately the one failure of the tests was to get an accurate value of what the vBatt voltage was. I know exactly what voltage the iCharger is putting out (verified and precise compared to the digital readout) but since the leads running from the iCharger to the battery pack connectors where relatively long and passing through my Turnigy power meter (as a backup current reading) I had to measure the actual voltage arriving at the battery pack off one of the deans ultra connectors using my DMM. No problem right?

Well so I thought but after doing 3 tests and seeing a consistent voltage drop (seemed rather large tbh), I touched the probe leads leading to the DMM with my hands and this consistently threw the reading off by as much as 0.3v. I checked all my connectors, resoldered aligator clips, swore at the crappiness of my DMM… tried another DMM (also a fairly cheap one) but I kept seeing the same thing, it seemed if I was touching the DMM or the leads in any way the readings would jump up 0.3v and give what seemed to me a more precise measurement. But leaving the DMM to do it’s thing it dropped way down again.

So I don’t know what’s going on, my theory is that the iCharger is not putting out a particularly clean voltage and that the buzz on that line is throwing off the DMMs, maybe my touching the circuit produces a slightly different waveform and a different voltage reading as a result. I dunno, it was really frustrating and I don’t have a scope to try and check anything high frequency related.

Anyway for now I don’t know how much voltage I’m actually feeding into the deans connectors at the battery pack but simply going by the iCharger voltages it already gives a pretty interesting look at the driver behaviour.

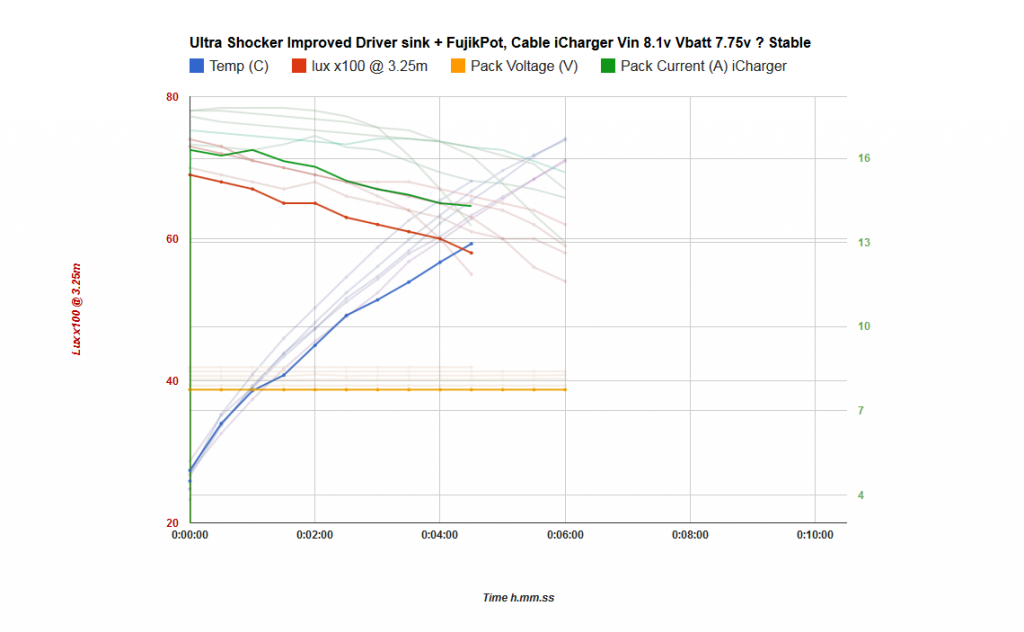

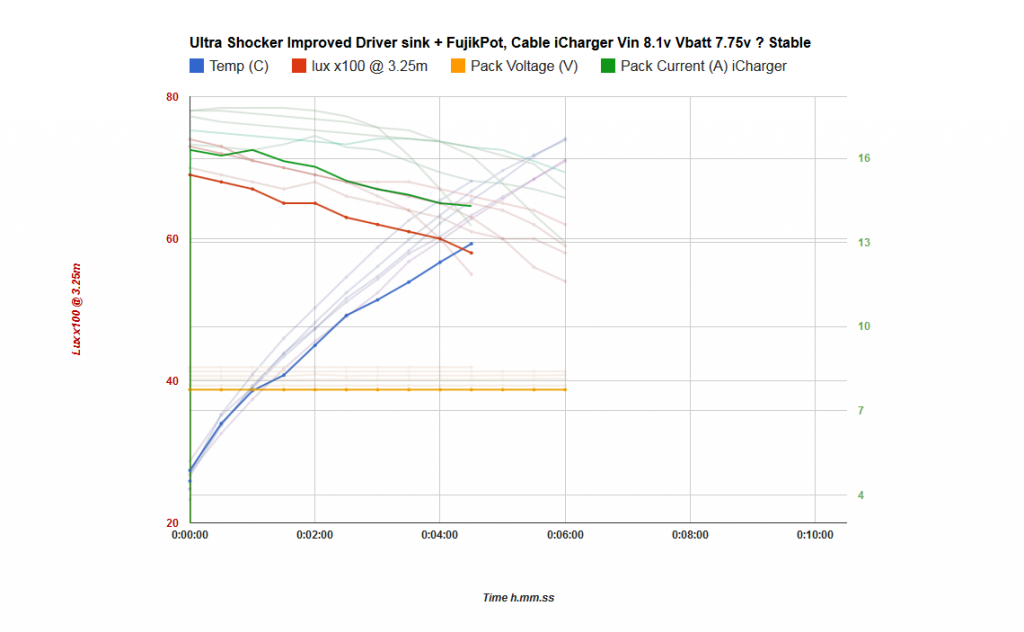

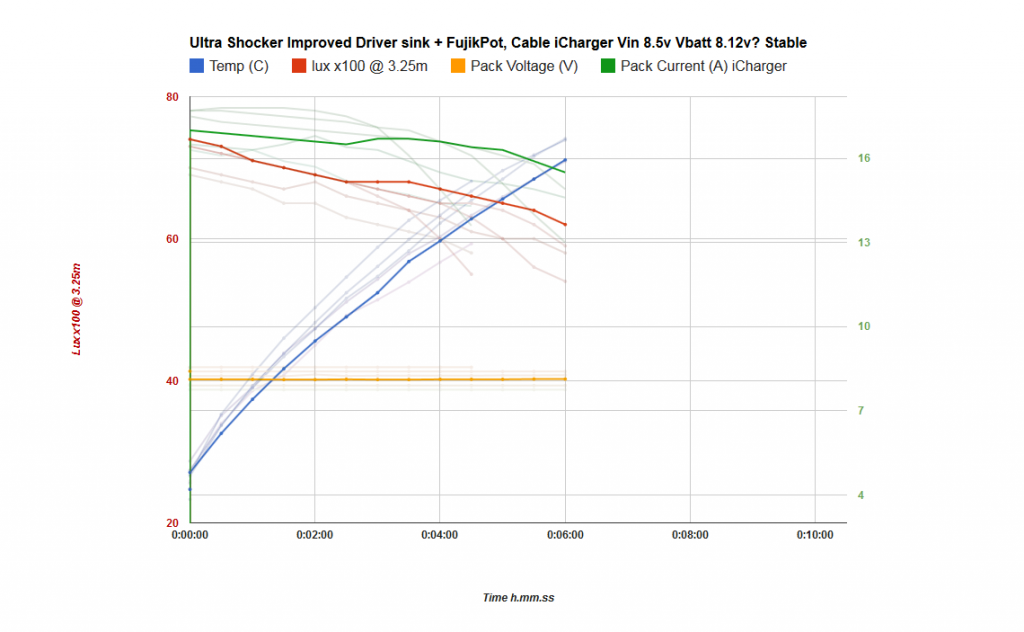

Let’s start with a low regulated voltage of 8.1, I was measuring 7.75v at the battery pack but as mentioned above, I can’t trust this reading. I suspect this may be closer to 8v at the pack.

Either way, this is not a good output graph, current is way below the regulation target of 17.5A, starts at 16.3A and output drops with temperature increase. Remember this is with no voltage sag in the supply at all! This test also ends early because my lipos powering the iCharger ran out before the 6 minute mark, too tired to run it again tonight.

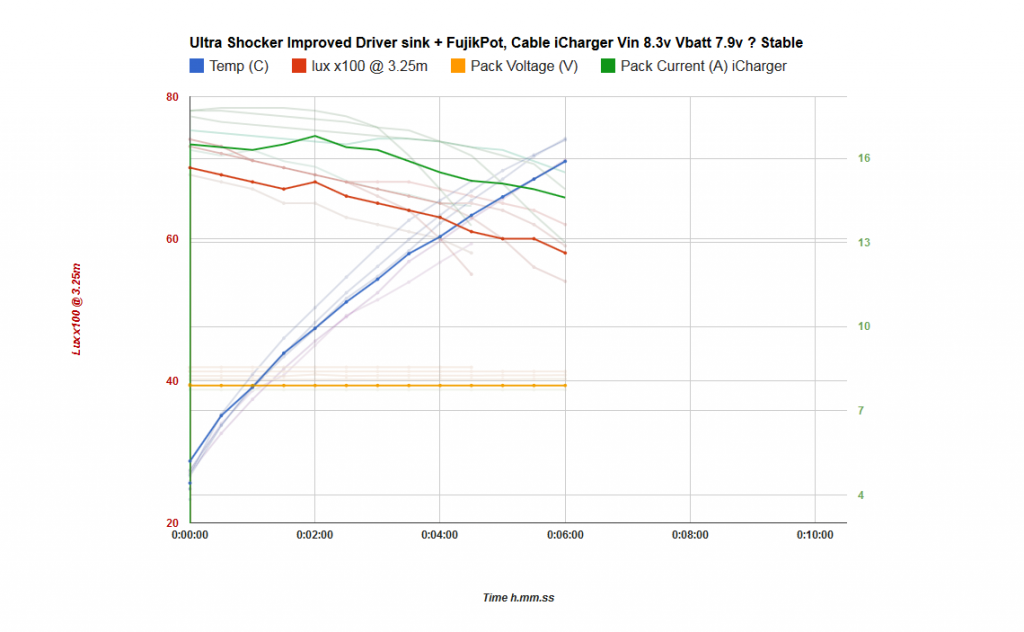

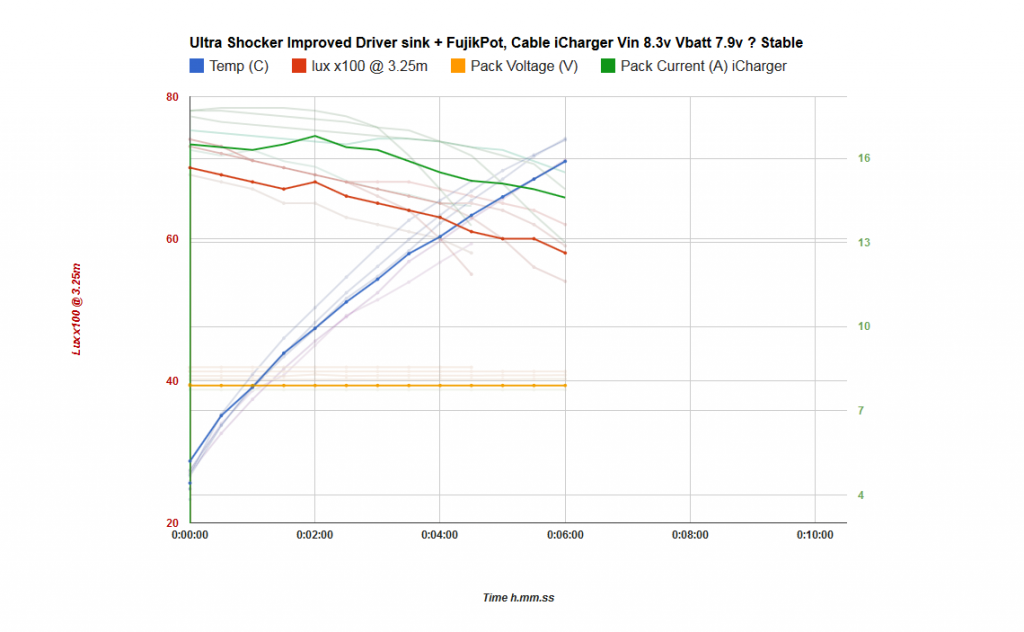

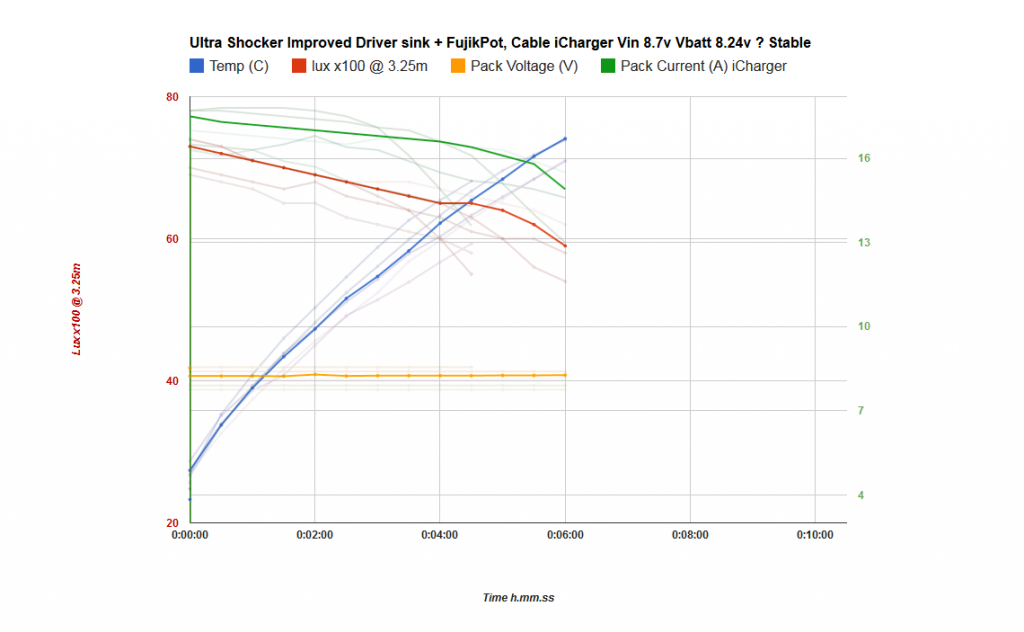

This one is at 8.3v on the iCharger. Funky stuff happens to the current here as the driver/light warms up, starting around 16.5A again it now peaks strangely to almost 17A at the 2 minute mark. I noted plenty of flicker on the troublesome emitter/driver during these tests as well.

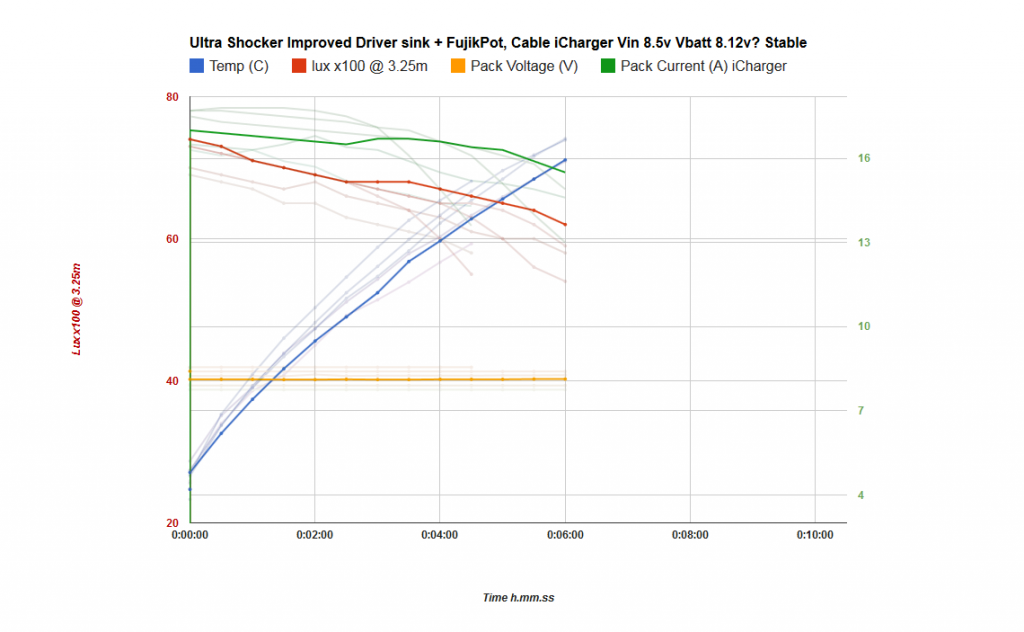

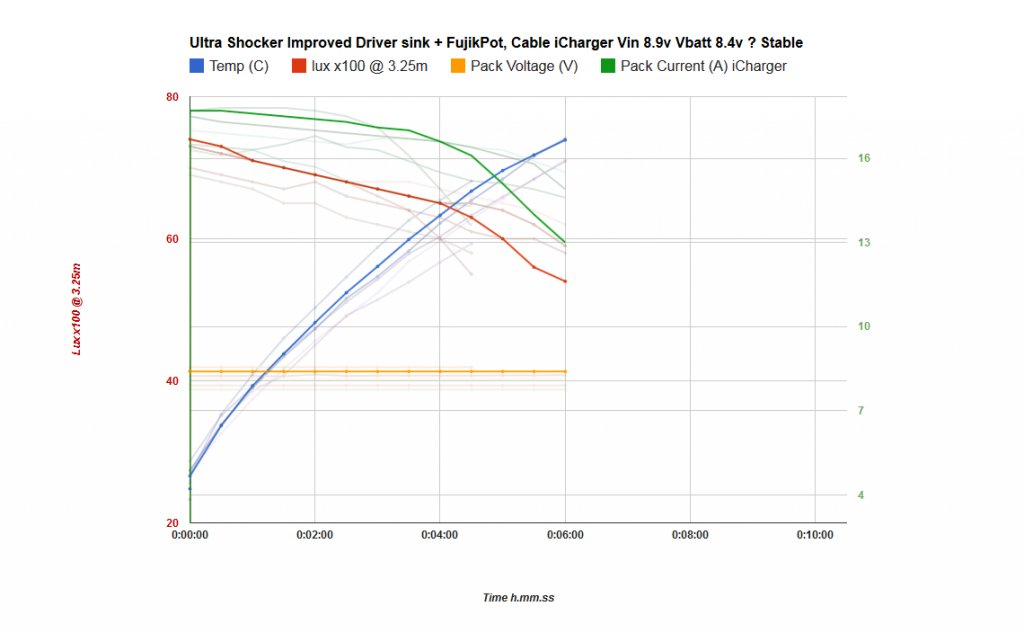

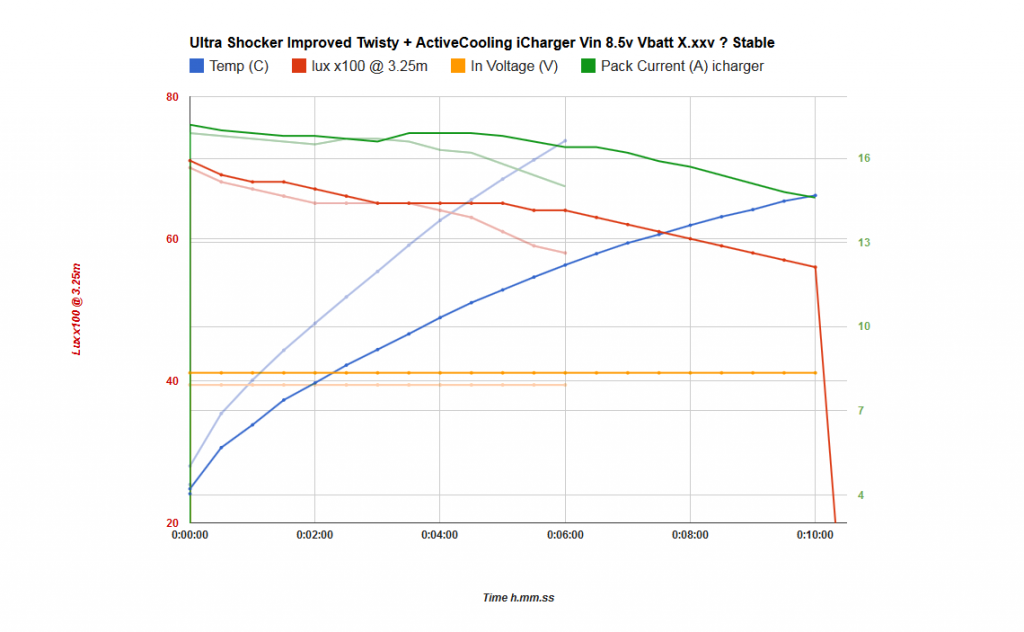

At 8.5v the current graph is looking rather similar to the no cable tests I ran earlier on. Still only starting out at 17A but relatively well regulated from there on. Steady decline at start and with that little bump at the 2.5-3 minute mark. Less flicker noted and actual output is maintained really well here, we’re still well above 60klux at the 6 minute mark which is great!

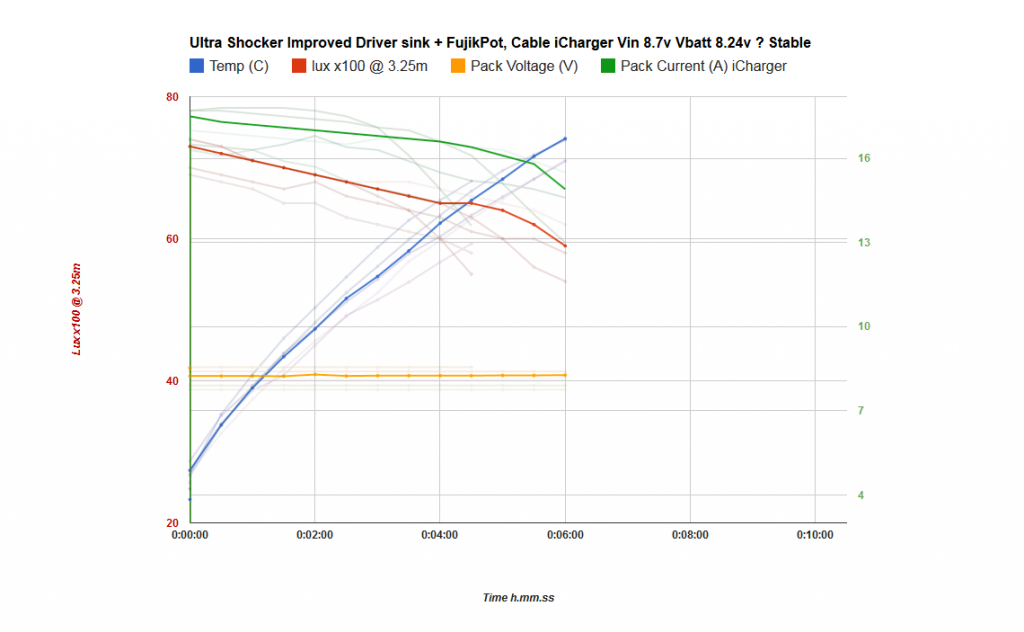

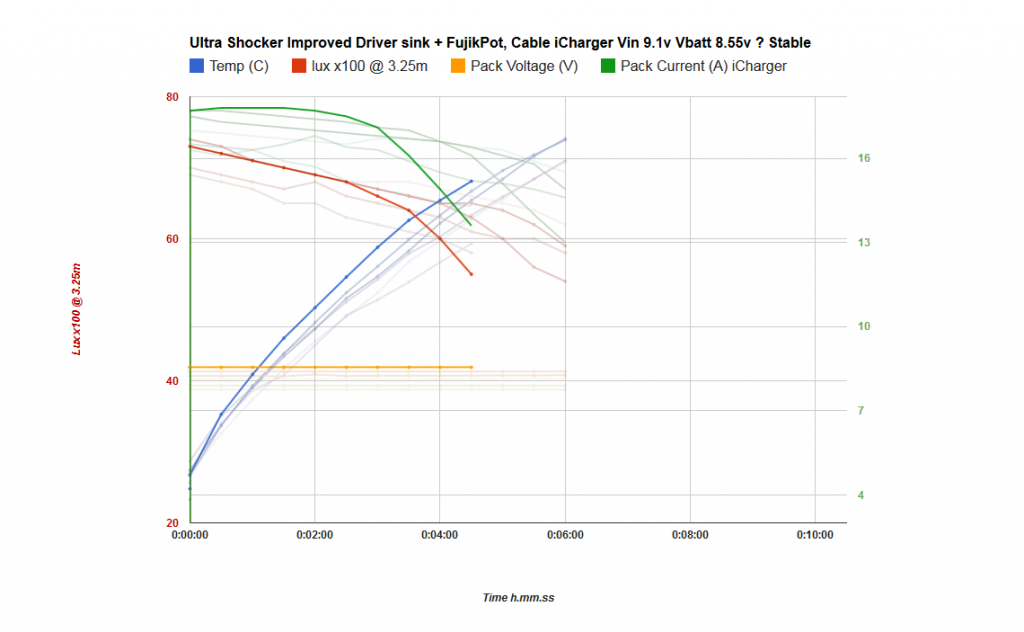

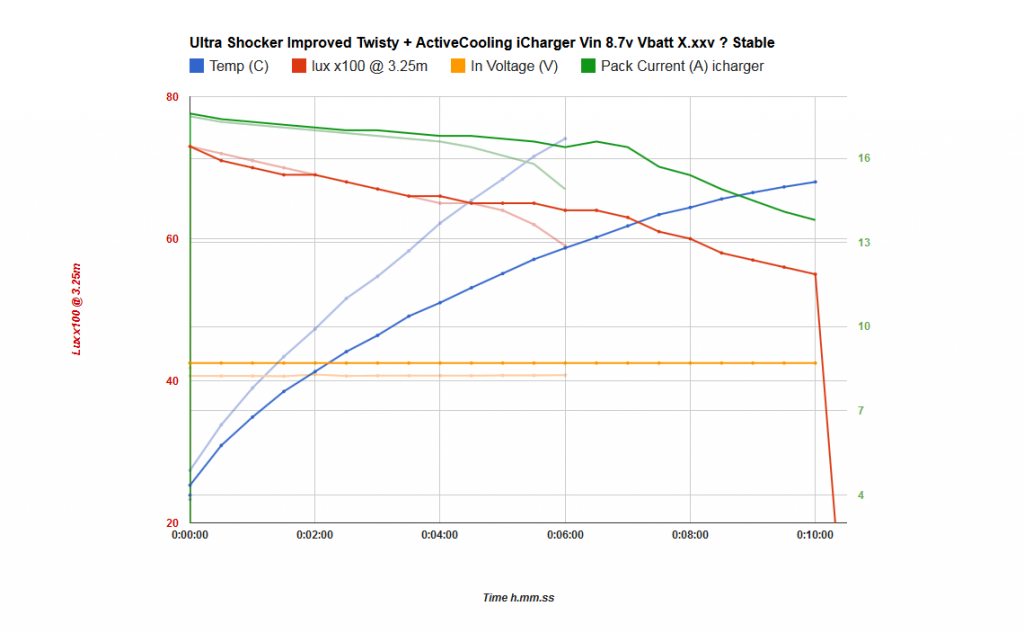

Well praise the lord does that look like a hint of regulation there?? I can’t believe my eyes, at 8.7v the current curve is very very clean. Not flat but this is more like what I expected to see. No funny business from the output side either and I’m almost certain I didn’t notice any flicker at all during this entire run. Of course because the drivers are now burning off more energy and also maintaining a higher output the heat cliff is very noticeable at the end of this run.

I still get the impression looking at this graph that the light is happiest running at this kind of voltage overhead, whatever that ends up being.

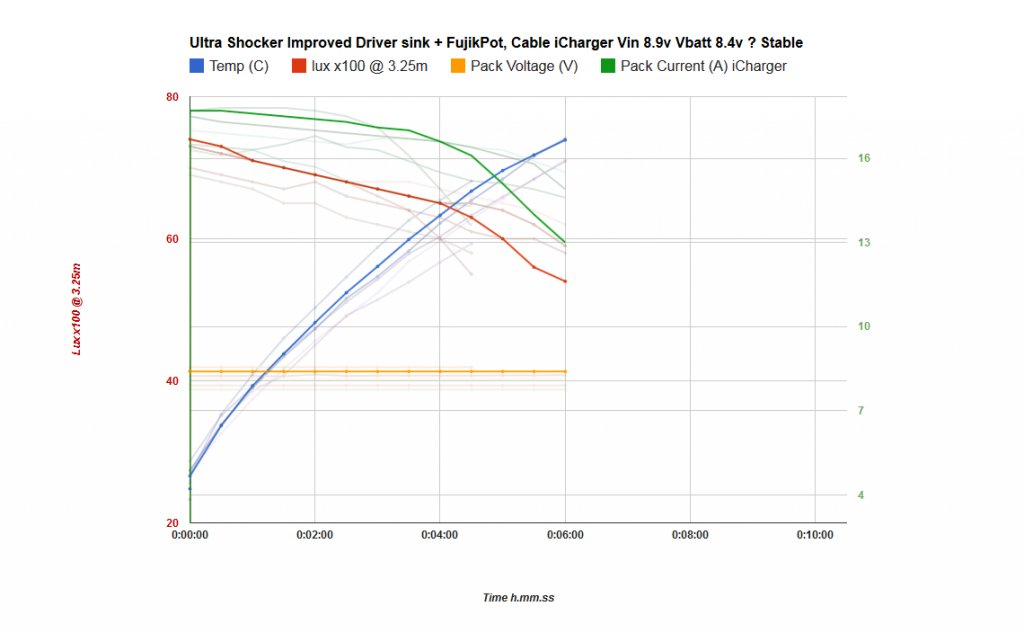

Now we’re starting to push it a bit, 8.9v shows a more extreme version of the previous test. But this is still the nice predictable shape to the curves that I was hoping for, the heatcliff is arriving earlier just as expected and output tracks identical to the previous test despite the higher drive current. I suspect that’s simply the emitters hitting a bit of a limit in terms of how much heat it can shift into the pill. Output beyond the 8.5v test seems to be determined more by the heatsink temp than the drive current.

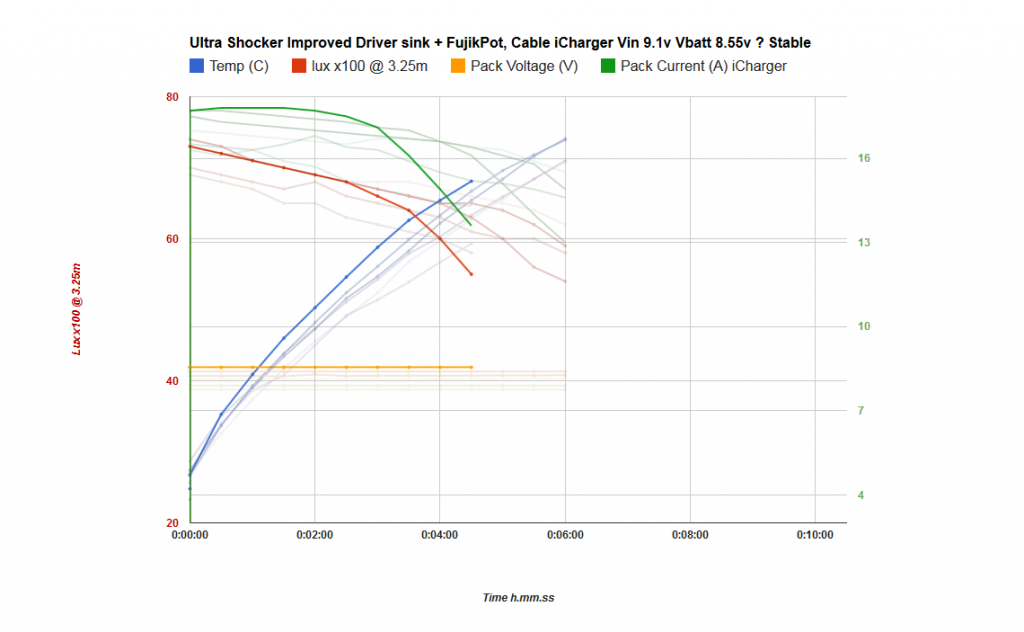

And finally the extreme torture test at 9.1v. Things don’t stay cool for long at this input voltage, the driver seems to peak at 17.8A (~0.3A higher than it should based on the number of 7135s i used, but hey up to now all I’ve seen is driver current missing the target in the other direction so I’ll take it…) then it drops as temps get critical. Output settles into it’s steady decline, identical in slope to the previous 3 tests and then follows suit over the cliff. This test was ended by one of those alarming mega flickers so I hope things are still ok in there

So that’s about it for now, it was a massive pain in the ass doing these runs. Waiting for the light to cool down to 24 degrees after each one and recharging my lipos in between every couple of runs. But I’m pleased with the insight it’s given me, once I figure out what my actual voltage drop is before the battery pack I’ll have an even better idea of what’s going on.

Plus it’s given me a really nice baseline that I can compared against when I go resistance hunting!

Ultimately I think I’m losing closer to 1.5v across all the connections and cables before we get to the driver, much more than the ~800mv I was hoping for.

But that’s just a gut feeling based on these tests and seeing where the regulation actually seems to start happening, I’ll know more when I have precise vBatt measurements to look at as well.

Thoughts really welcome, does this look familiar to those who know these 7135s better than I do? To me they seem to be doing really funky stuff that I never considered before, especially in the range where they are presumably just switching in and out of regulation. I also thought their behaviour would get MORE erratic as the voltage overhead and temperatures increased but frankly they seem to run much more predictably in those conditions…I’m a bit lost tbh!

Haha bring on the linear FET drivers!

Cheers

Linus

![]()

![]()

If so this would greatly increase the density in the battery increasing efficiency and greater lumen output.

If so this would greatly increase the density in the battery increasing efficiency and greater lumen output.