I finished the coating and tested the results. The news is bad and the news is good. First some pictures:

On the left is the wrong paint I used for the first layer on the polystyrene, on the right is the latex paint that I used for two more layers, mixed with BaSO4, it is visually the same white as the BaSO4 powder in the middle. I made the 60/40 BaSo4/latex-paint mixture much thicker than for my first sphere, so I sufficed with two layers, the combined thickness was more than what is inside my first sphere.(for a background why I use this mixture, see my first 'Floating lumens' thread)

A picture of the BaSO4 powder next to bare polystyrene, also pretty much the same white visually (part of the polystyrene can be seen painted with the off-white latex).

After finishing the coating:

The sphere was put inside the wooden box, the holes matching the holes in the wood and the sphere firmly clamped in position by some cushioning leftover from flashlight packaging.

Then the lid was screwed in place.

I let the paint dry for a day and measured the reflectivity (the output of the cfc-light and my SWMD40A on high setting), then again two weeks later. In those two weeks the reflectivity of the sphere went up 1.02%, I hope that was still the paint drying for the last bit. Now it is two days later again and the measurements are exactly the same as two days ago. I will confirm (I hope) that is still the same a month from now.

The reflectivity of the coated sphere compared to the bare sanded styrofoam had gone down significantly (like in my first sphere) , by a whopping 37%. This is not nice because that reduces the integrating properties of the sphere. Luckily all my observations suggest that the integration is still pretty good. Because the total reflectivity is a combined result of a large number of reflections taking place inside the sphere, the decrease in reflectivity of a single reflection is much less of course. To get an idea, a few months ago, to get a feeling for my first sphere, I calculated the combined reflectivity after 17 reflections (adding more reflections to the calculation does not change the number much anymore) for two efficiencies for single reflection: 88% and 90%. After 17 reflections it comes to a difference of 13.6%. I could try to calculate what the difference for single reflection would be for the combined difference of 37%, but being a bit lazy, I estimate that on 6%. Ok, a bit less lazy, I just calculated it for 90% and 84% efficiency for a single reflection, after 17 reflections the difference is 30%. So the loss in reflection efficiency is even a bit worse than 6%  .

.

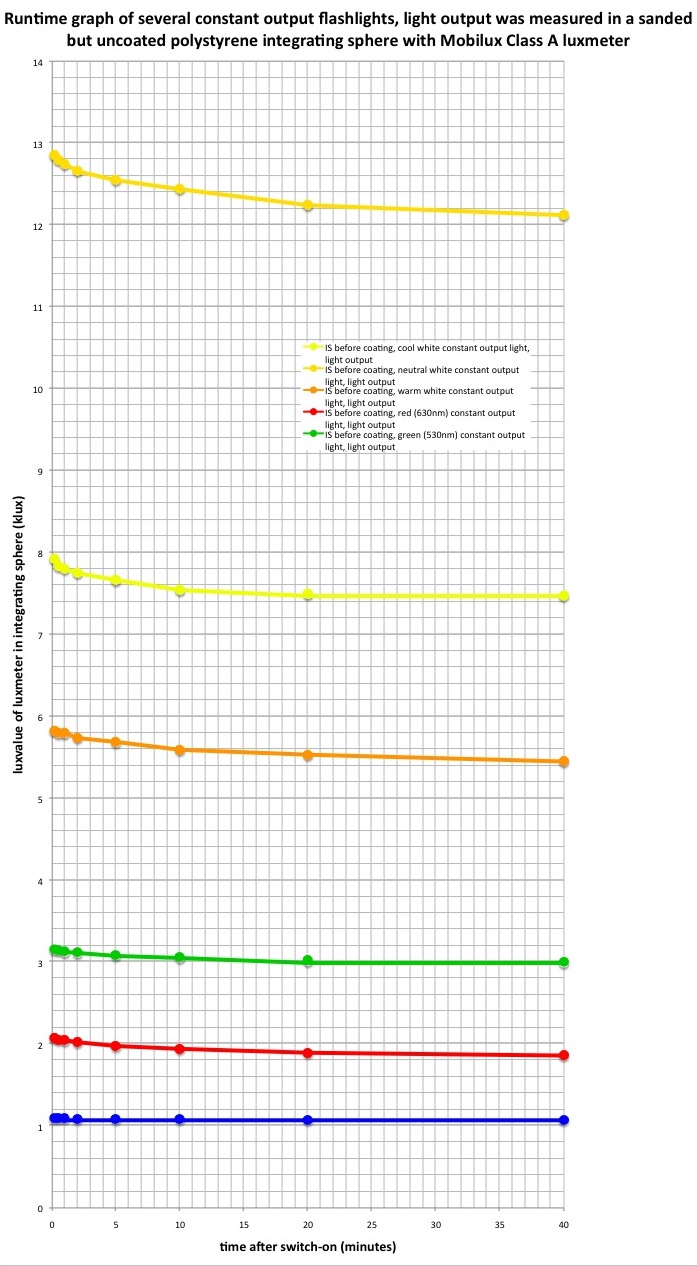

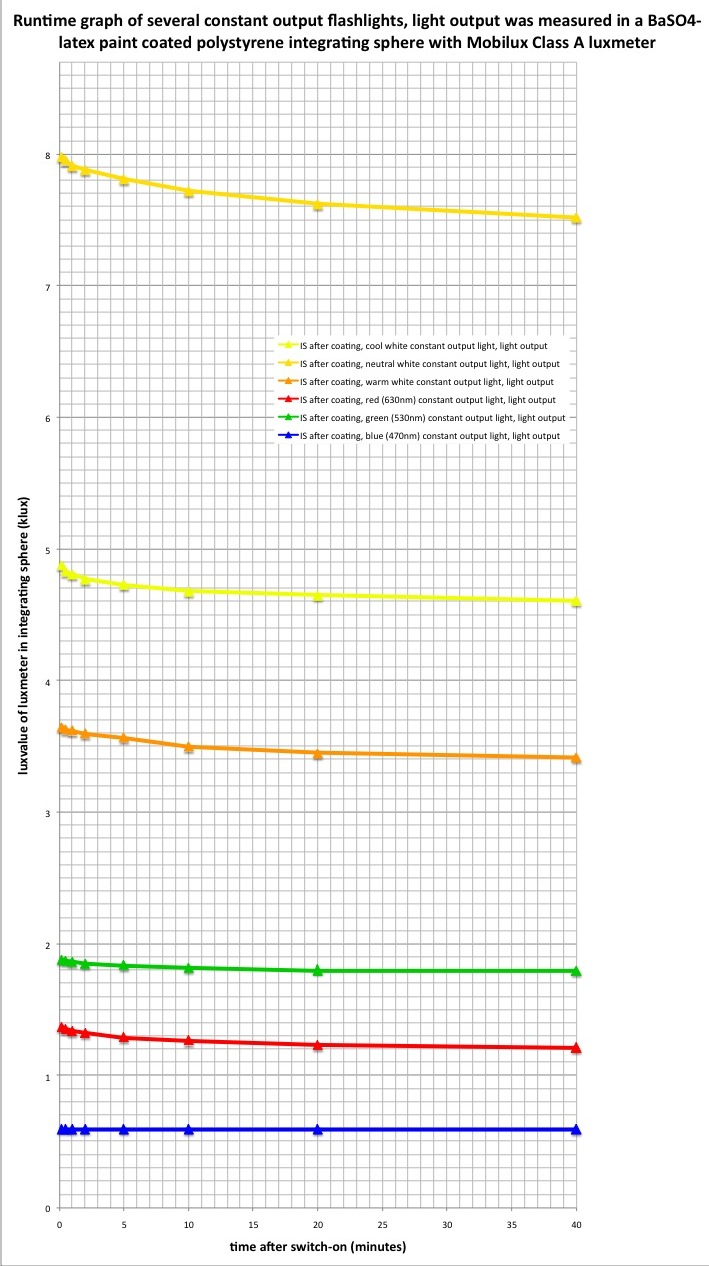

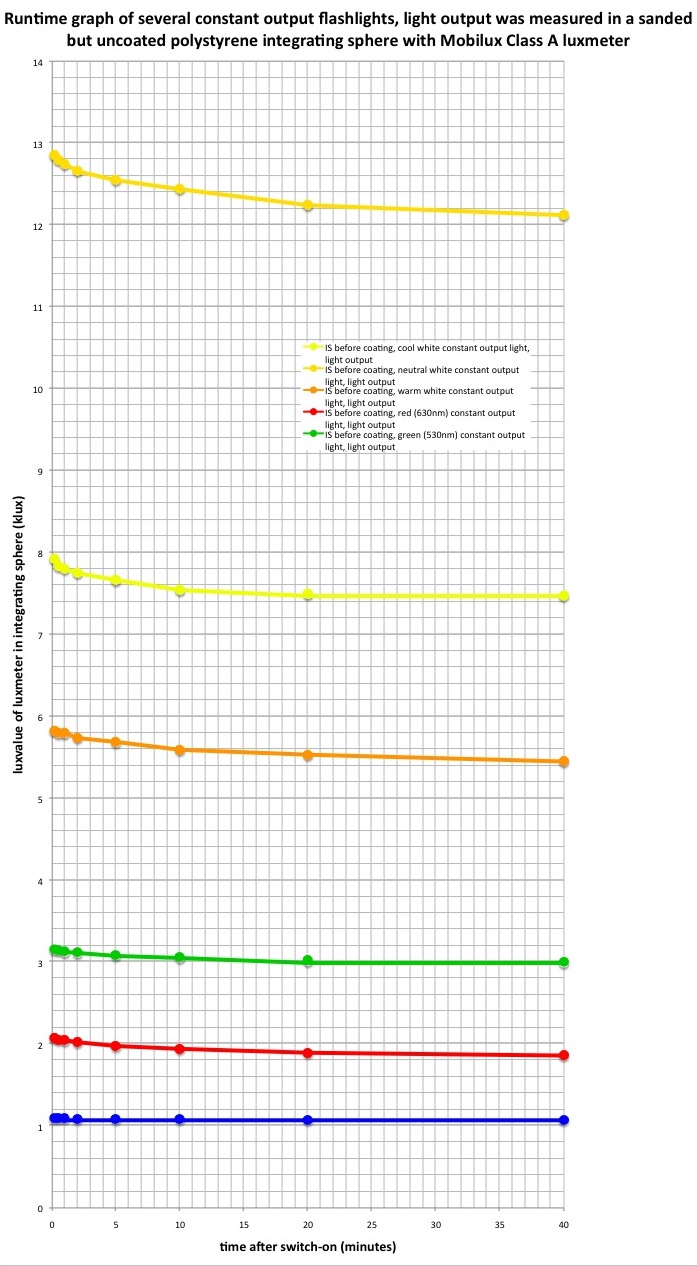

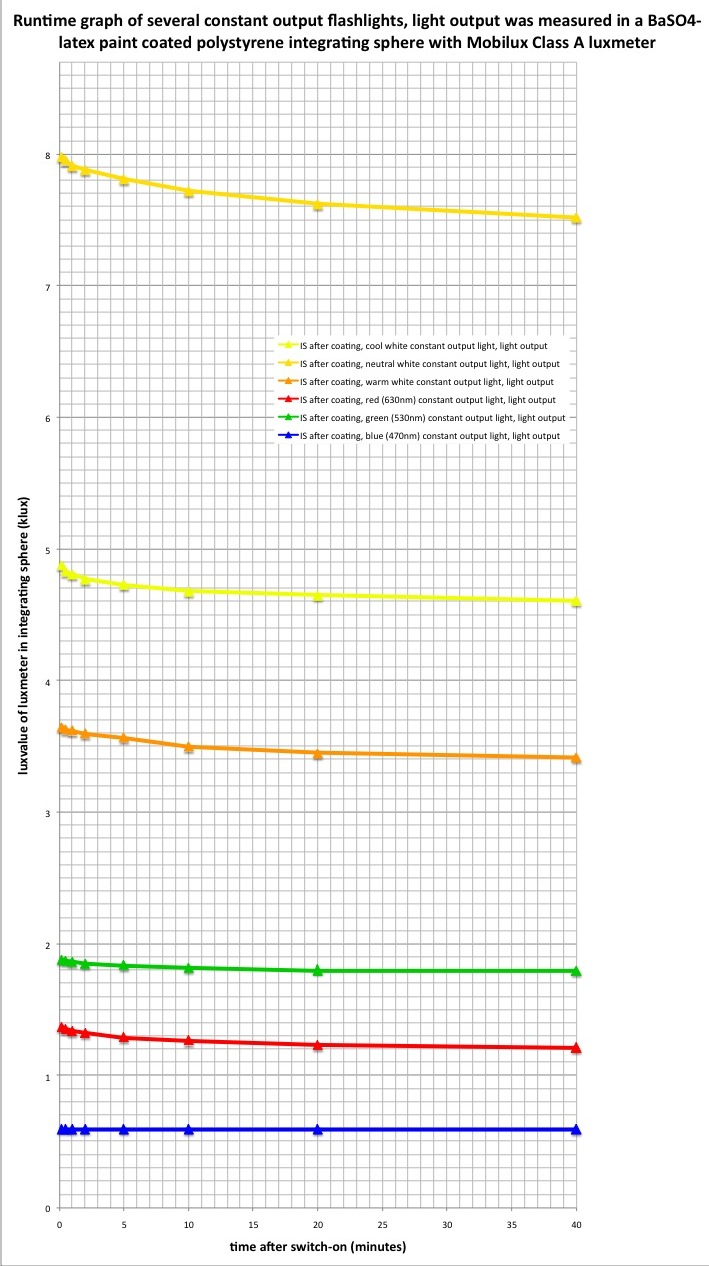

So, if not for the reflectivity of the sphere, the coating must be good for something, right? At least the reflectivity for different light colours must have become more constant. A good integrating sphere must have the same reflectivity for all colours. Unfortunately I can not measure reflectivity directly, what I can do is measure the luxvalues inside the sphere of different coloured constant light sources before and after coating. If the percentual difference in luxvalue before and after coating differs for the various colours (sorry for this horrific sentence, any virtuosity in the english language really leaves me here), the coating has had an influence on the respective reflectivities over the colour spectrum (improved or gone worse I can not tell).

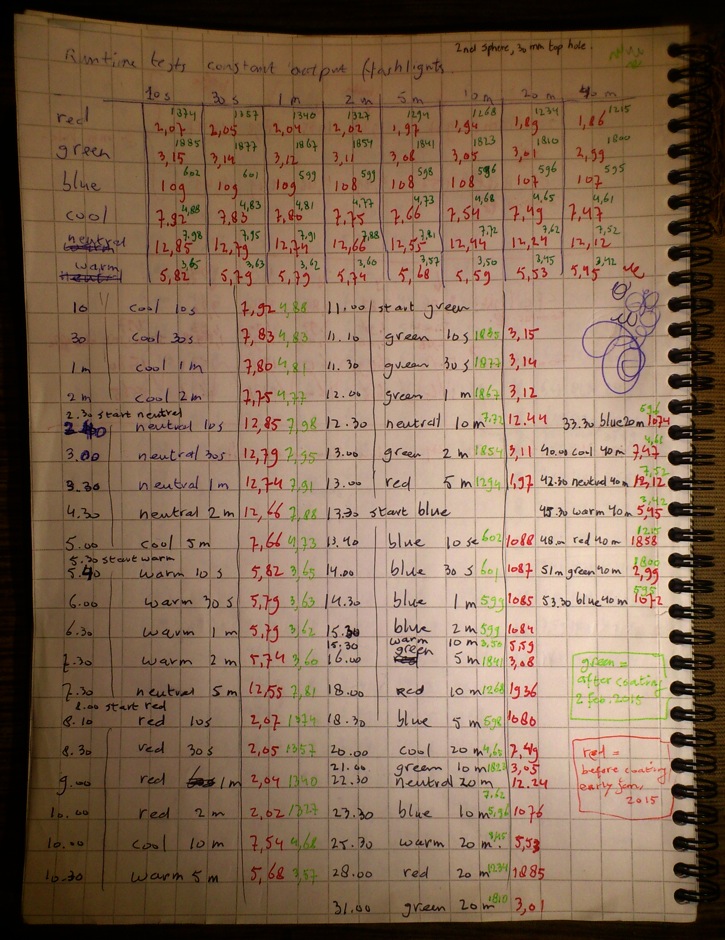

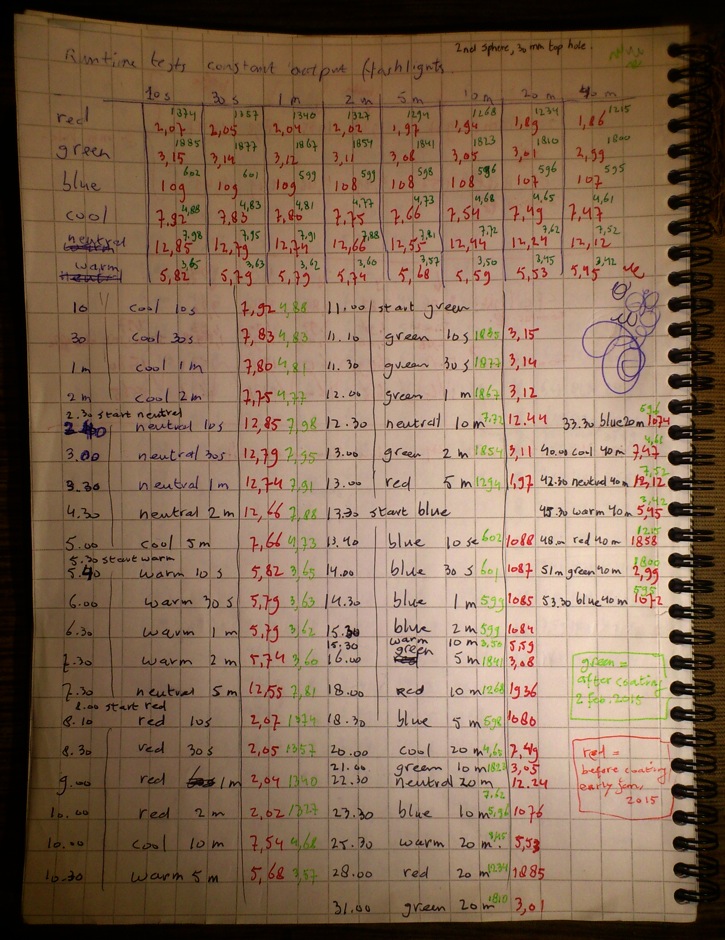

So I did the runtime tests again for the constant output flashlight that I measured in the uncoated spere as well. To get an idea in what analog age I am stuck:

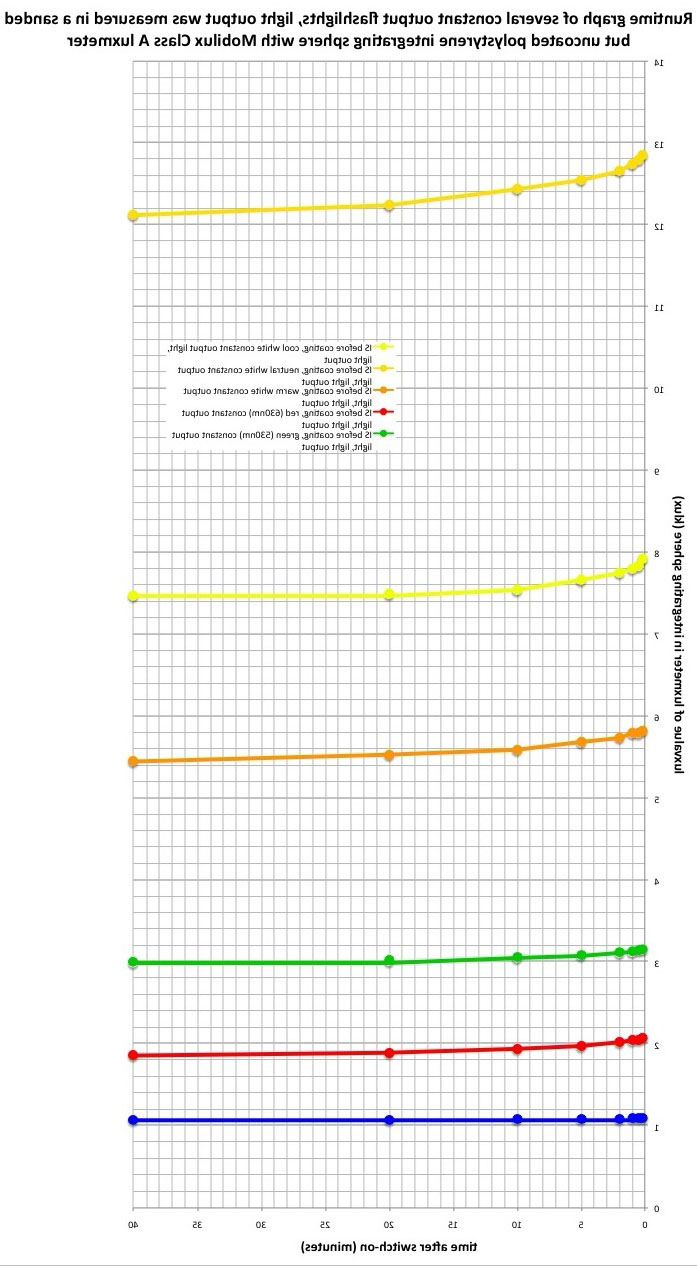

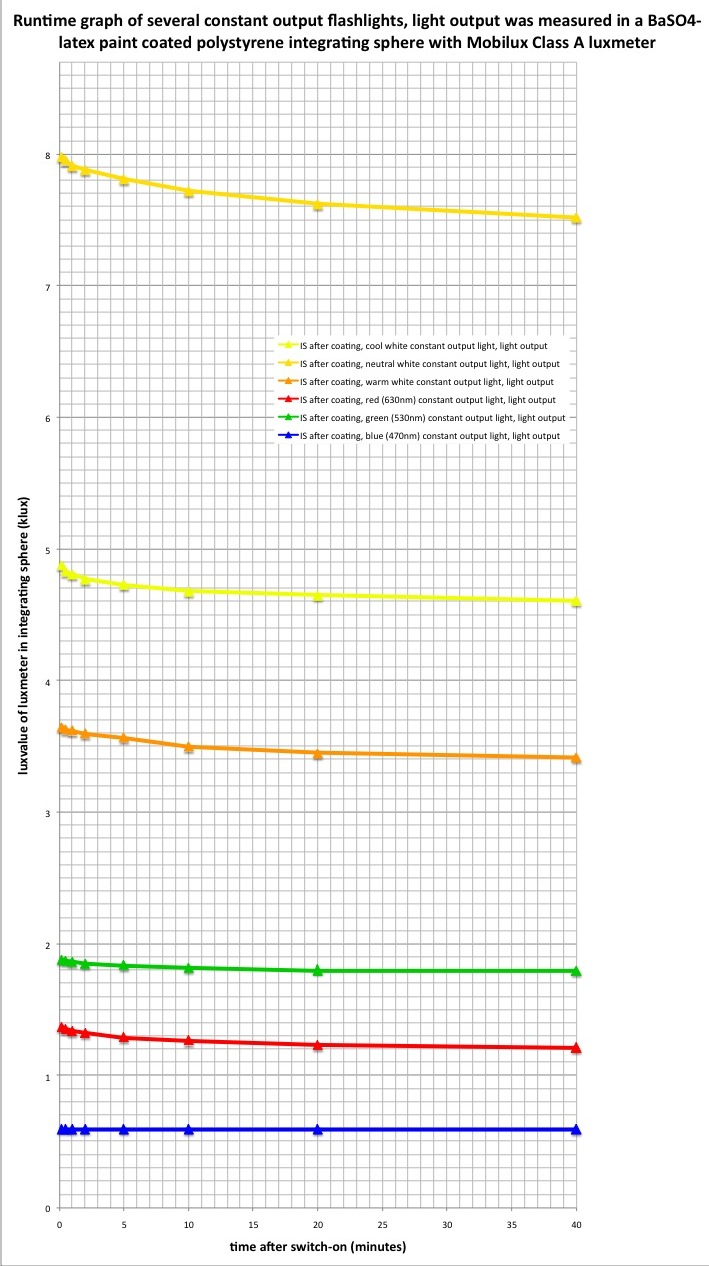

Then I made the exact same graph that I made before coating of the sphere (see post #38), I only altered the scaling of the vertical axis, to set the runtime curves of the neutral white flashlight before and after coating on exactly the same level. So then it is easy to see if any curve has shifted (this only works if your display is wide enough to show the two sets of graphs next to each other):

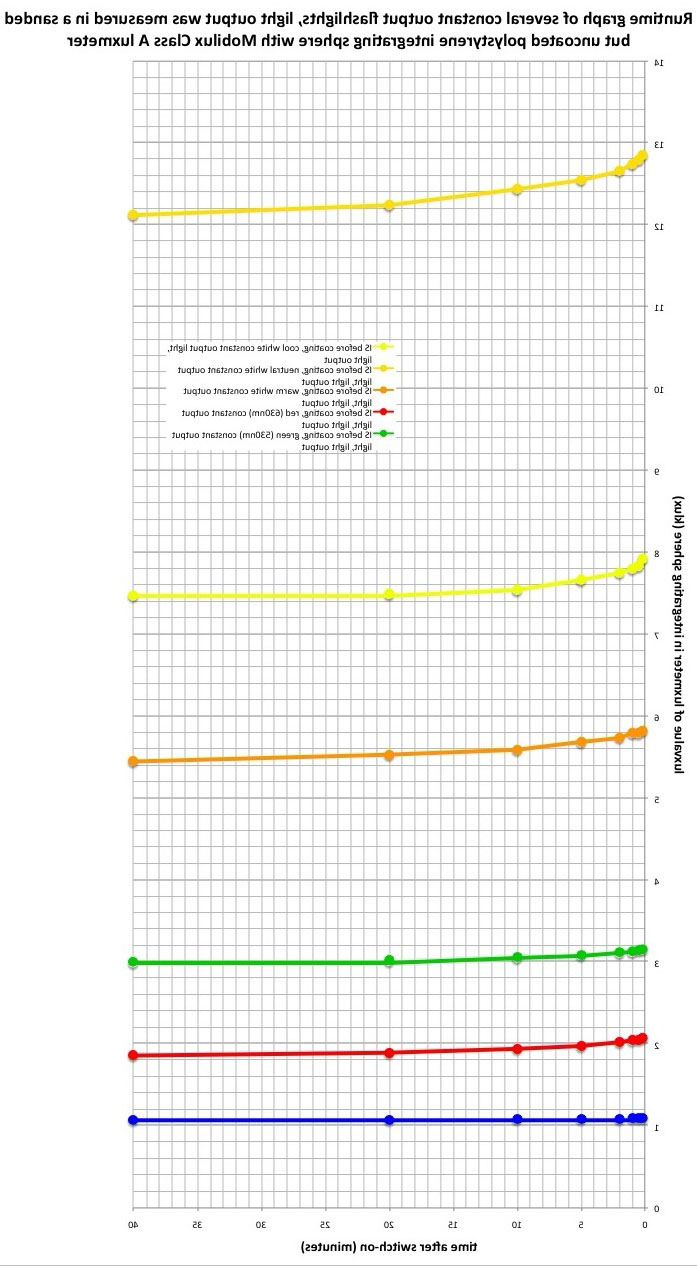

Hmm, that difference is not great, let's flip the uncoated graph, so that differences are more easy to spot:

Still looks very similar, but there are changes, of course most clearly for the single colours. After the coating as compared to before coating, if the neutral white curves are defined equal (just to have an off-set), blue measures (about) 10%lower, red 10%higher, green 3%lower, coolwhite 0.7%lower, warmwhite 1.5%higher. Am I impressed by the changes in reflectivity over the colour spectrum that the coating causes? Not really. The extreme colours blue and red do have a clearly altered reflectivity, but not many will want to measure them very accurately (maybe me ;-) ). What matters in the real tough flashlight world is the different whites, and going from 3000K to 6500K the difference uncoated vs coated is only 2.2% (from neutral to cool only 0.7%).

I assume here, because I did some research on what substance to use, that this coating improves the constantness of reflectivity of the integrating sphere over the colour spectrum. But I did not find anywhere how good bare styrofoam already actually is in doing that (perhaps very good, who knows?). It is not unthinkable (I do not like that thought of course) that the difference that I find here are not an improvement but a change for worse. I just measure relative changes, not absolute reflectivities.

My conclusion about coating with BaSO4/latex mix? Because the effect is not that great, and because I do not even know for sure if that not so great effect is for the better, and because it is a messy and tedious job: just don't bother! And that is bad news because coating my spheres was apparently not really worth the effort, and that is good news because this makes all those uncoated styrofoam integrating spheres out there just a bit more trustworthy :-)

Thanks for the update.

Thanks for the update.

.

.