It’s not a threshold. It’s more of a usage pattern.

If a device uses a small steady trickle for a long time, it may be hard to tell when the cell needs to be recharged. A wall clock, for example. It can drain too far, so that by the time it fails, the cell has already taken a hit.

If a device infrequently uses a small portion of the total charge, then rests a long time between, the cell might spontaneously recover between uses. For example, a keychain light used at 10 lm for a few minutes once every few days. This makes the charge rock back and forth across the “empty” line.

However, I also have a ZL SC52 running on moon mode (0.1 lm) all night. It lasts about two months per charge. I don’t have this problem on that device, because it lets me know when the charge is too low. It’ll run fine at first, then when it goes too low it starts blinking at me and I know to recharge it. So, a 3-4mA drain is fine, as long as it lasts long enough to push past the spontaneous recovery, and the device then warns about low voltage.

What I want to avoid is over-draining and repeated recovery without a charger. These both seem to reduce the long-term life span of Eneloops.

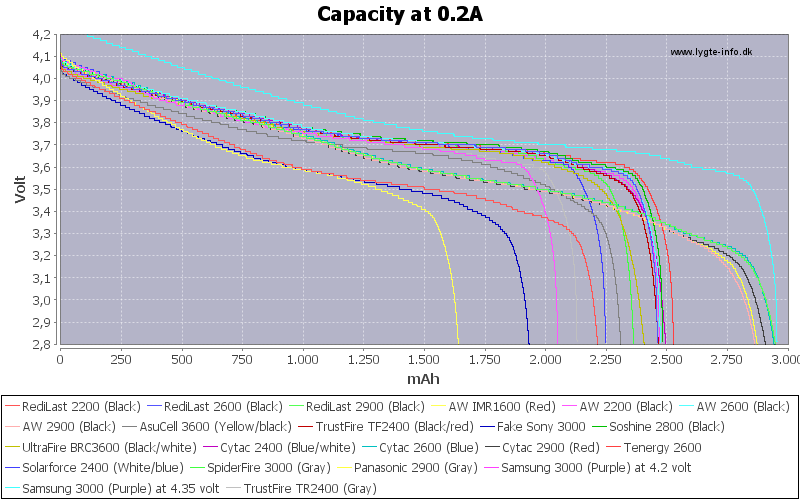

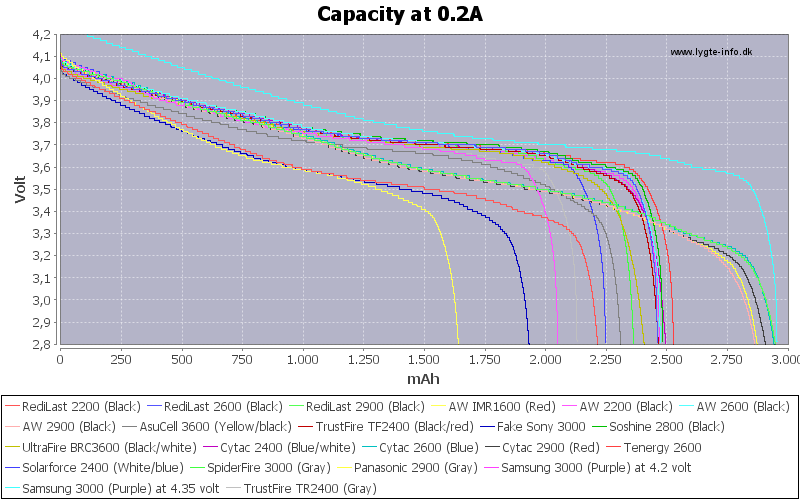

Li-ion cells are somewhat easier here, since they work better when the charge stays away from the top and bottom of their range. If they get drained to 2.8V and charged to 4.25V each time, their life span will be shorter than if they stay between 3.1V and 4.15V. They’re quite happy to stay in the middle.

In any case, if a light is on a low mode and voltage drops below 1.0V (Eneloop) or 3.0V (li-ion), it’s almost certainly time to recharge immediately.

/Eneloop%20AA%20HR-3UTGB%201900mAh%20(White)-Capacity.png)

The main place I run into li-ion issues is with phones. Apparently phone manufacturers think it’s imperative to always be at exactly 100% charge whenever possible, so they charge up to 4.37V or so (4.35V cell) whenever plugged in. And then drain a few percent, then charge back up a bit over full, then drain, then charge, etc, with a cycle time of anywhere from a few minutes to a couple hours. Leaving these phones plugged in all the time effectively over-charges them a dozen or more times per day. And then within a few months, people start to notice that the back of their phone is no longer flat. If they’re really unlucky, the screen will bend outward too. Then after perhaps a year, the battery capacity is a fraction of what it once was. I have phones only a year old which practically roll when I put them on a flat surface. And it’s an uphill battle convincing the relevant people that this is fixable and worthwhile.

Sorry for the long post and tangent. It’s almost time for the sun to come up, and I’m overdue for a nap.

![]()

/Eneloop%20AA%20HR-3UTGB%201900mAh%20(White)-Capacity.png)