Received one week ago this little brass light: Olight I3S-CU Polished finish:

Olight I3S-CU Polished finish: (made of brass)

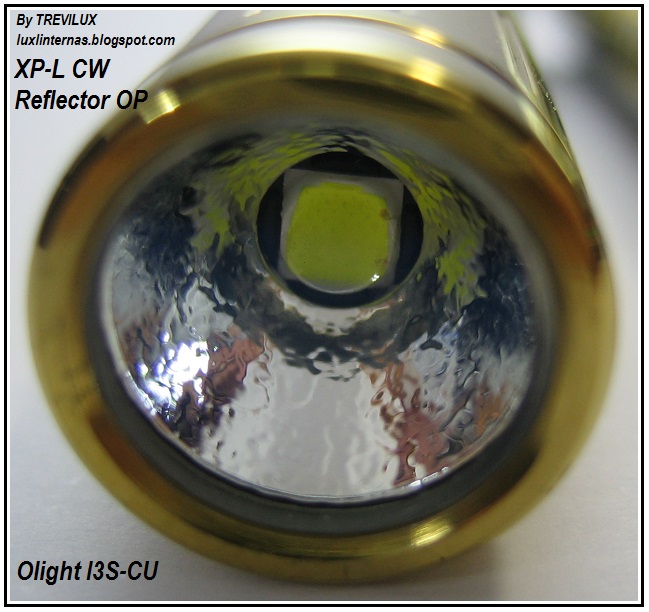

LED: XP-L Cool white

REFLECTOR: Orange peel

BATTERY: 1xAAA 0.9-2.0 V (NiMH, Alkaline, primay lithium).

MODES: 3 HIGH/MID/LOW

INTERFACE: Twisty

DATE: February 2016

FROM: Olight I3S-CU hkequipment.net

Packaging, perfect for carrying the flashlight, to give away or to store the flashlight. Includes one alkaline battery ( I am not a big fan and, I will use with high quality NiMH aaa) and a Manual user, but I miss one spare oring.

The light not change the size of his predecessor I3s aluminium version, but the weigh is increased for the new material:

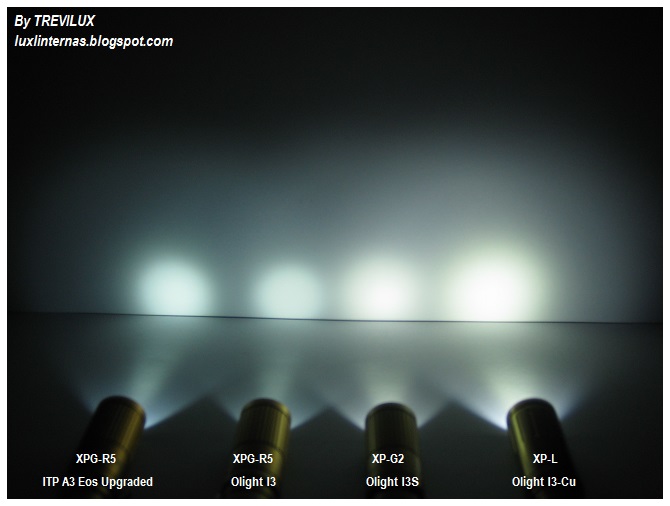

Some Pics now for comparisson with other "3 Series"; ITP A3 Eos upgraded (XP-G R5), Olight I3 (XP-G R5) and Olight I3S (XPG-2):

Now Pic with a Maratac aaa copper Rev3, my first copper flashlight, I am not sure yet if I will be a fan of copper lights....(but I love this Maratac!)

and with other well known aaa flashlights:

Some pics for detail of design; tailstand is allowed, the threads have a good quality and run very soft. The clip is strong enough for this little size. head to head with the auminium version, only 2 small external aesthetic differences:

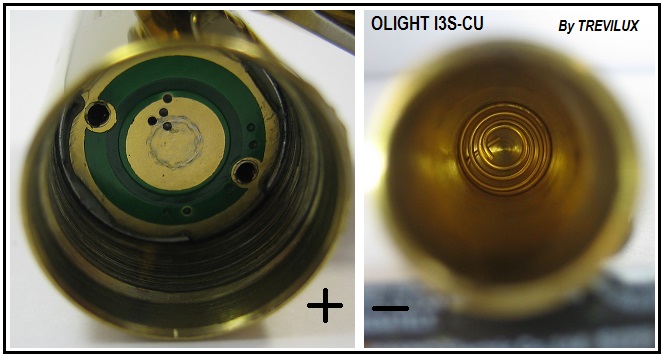

Battery and Interface:

Information from Olight says; 0.9-2.0V, and of course I will no try 10440 on this. I prefer NimH and Primary Lithium.

Is a Twisty light (tighten and loosen head for changing modes).

No memory modes, always turn on the highest mode. The sequence; High,Mid,Low,High,..... (this I3s-CU has not hidden strobe as the I3S aluminium version)

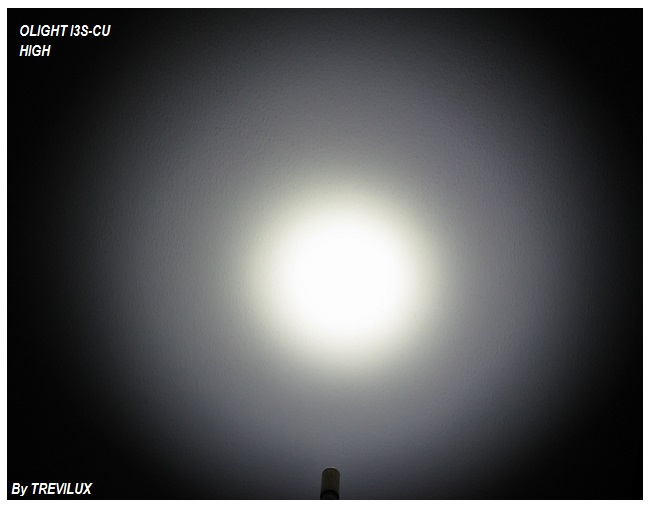

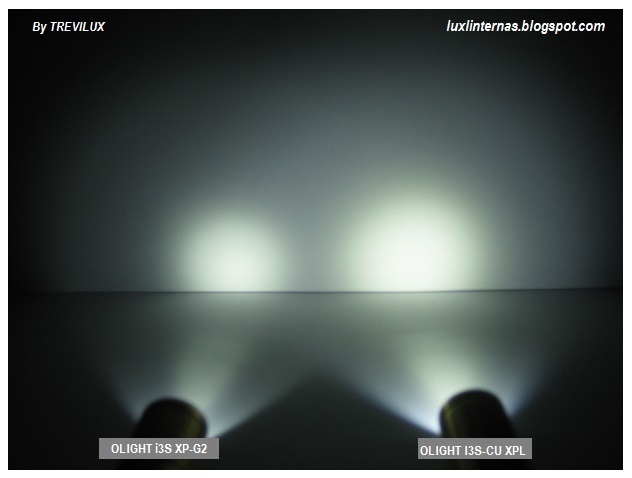

LED/BEAM:

A XP-L Cool white welll centered in small Orange Peel reflector. Perfect beam, more flood than his colleague in aluminium:

A animated gif:

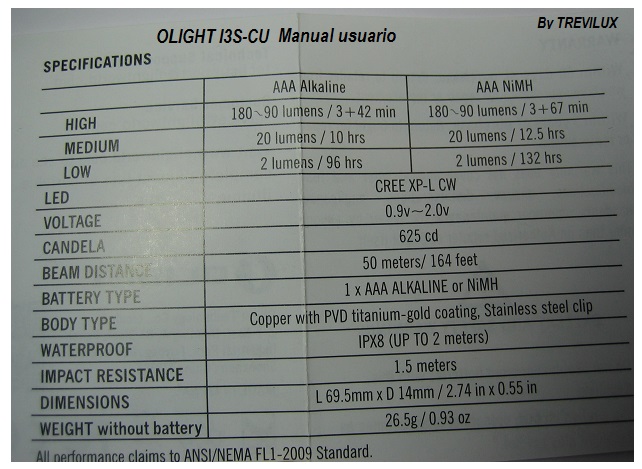

Information about modes and runtime in high:

Official information manual:

First I put a small graph of relative power modes in % to get an idea of which is the distribution of modes. Considering that the flashlight has 3 modes, but how high suffers a drop in power "step down" programmed for 3 minutes, I have included the value of this step as a reference within the graph;

(ceilling bounce)

Runtime test in High mode with a Panasonic Eneloop NiMH min. 750 mA. One data for minute, for reference the 100% on this test is the highest value between 30 and 180 seconds (ANSI NEMA FL-1 standard).

In detail the first 4 minutes of test, one data for each 10 seconds. The step down begins at 3 minutes, slowly descent for 30 seconds to about 45% of initial power and then the line is flat:

I love the light, my score is 9/10. (for the price is a perfect 1xaaa, but I will prefer a diferent order of modes, my preferred for aaa lights is low/mid/high).

This sample was not provided for review.

PLEASE COMPLETE REVIEW IS (IN SPANISH) HERE, http://luxlinternas.blogspot.com.es/2016/02/olight-i3s-cu-polished-finish-1xaaa-xp-l.html