I must be the only one modding today, last mod was mine too ;-)

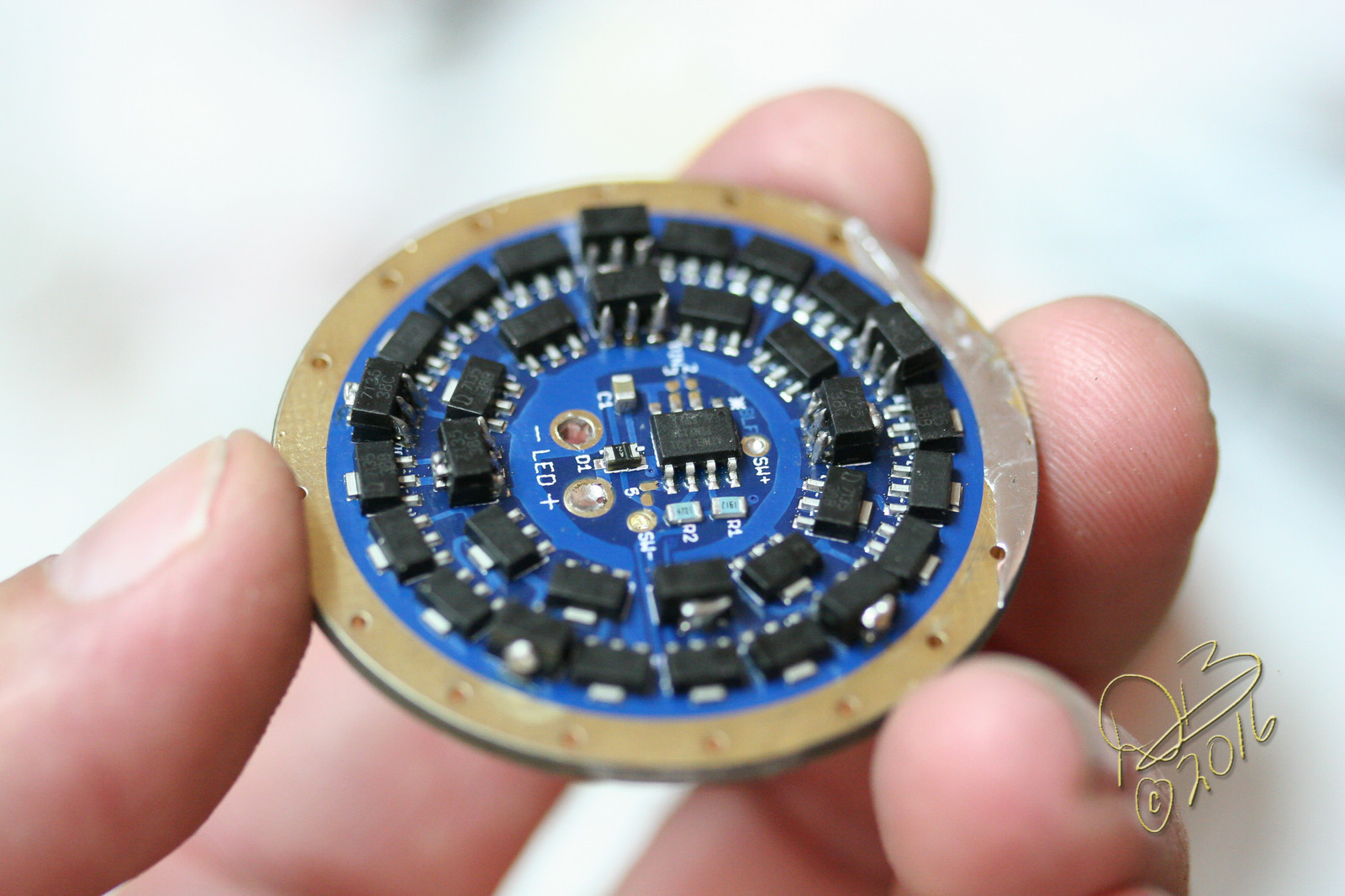

Ok, so I liked the led, today I made the triple: my shorty bare BLF-A6 (dedomed XP-L 5A led) had a non-descript yellow-ish low CRI just under 4000K tint, time for the triple Square 3000K 92CRI. The parts:

The result (how to draw an owl ;-) )

It was not all great:

-even though I used the stock lens over the optic, the o-ring kept popping out (when do the chinese learn to make a proper groove for the o-ring instead of a flat shelf?), finally I found a thin black o-ring from a sk68 clone that did the job fine.

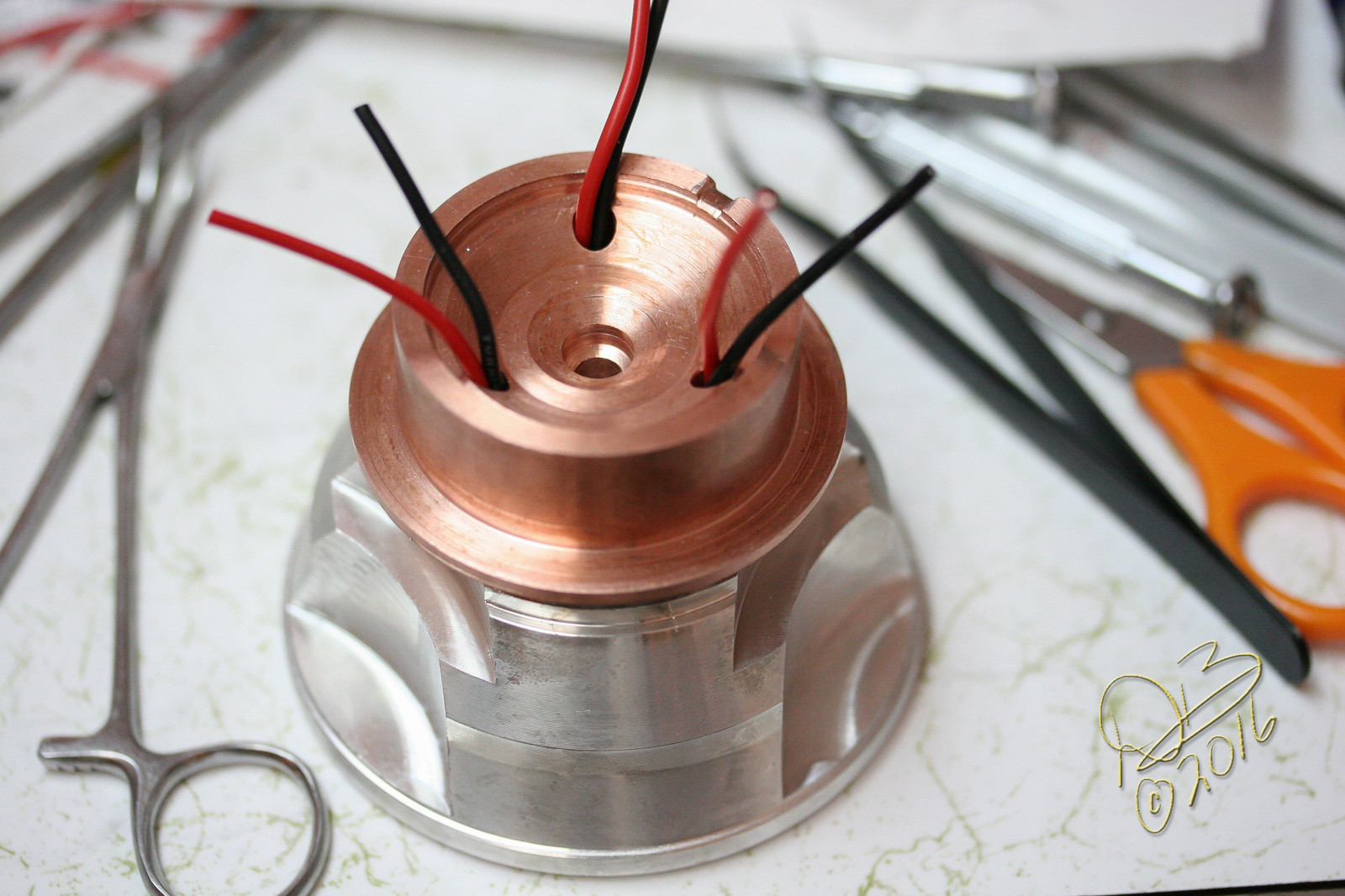

-I fried a switch because I shorted the light at the driver spring because of an improper spring bypass, had to solder a new switch in (small Omten)

-the spacer was 1.5 mm too thick, so the head did not close fully, which would have been fine if not the threading is so loose (sloppy manufacturing) that the head pulls itself at a slight angle when tight :sick: . The only solution is disassemble and sand a mm off the spacer so that the head tightens over the rim. Someday I will do that :tired:

-I love my new 80W solder iron, I use it for ledwire-to-copper-board soldering, done in a second: it is a beast!

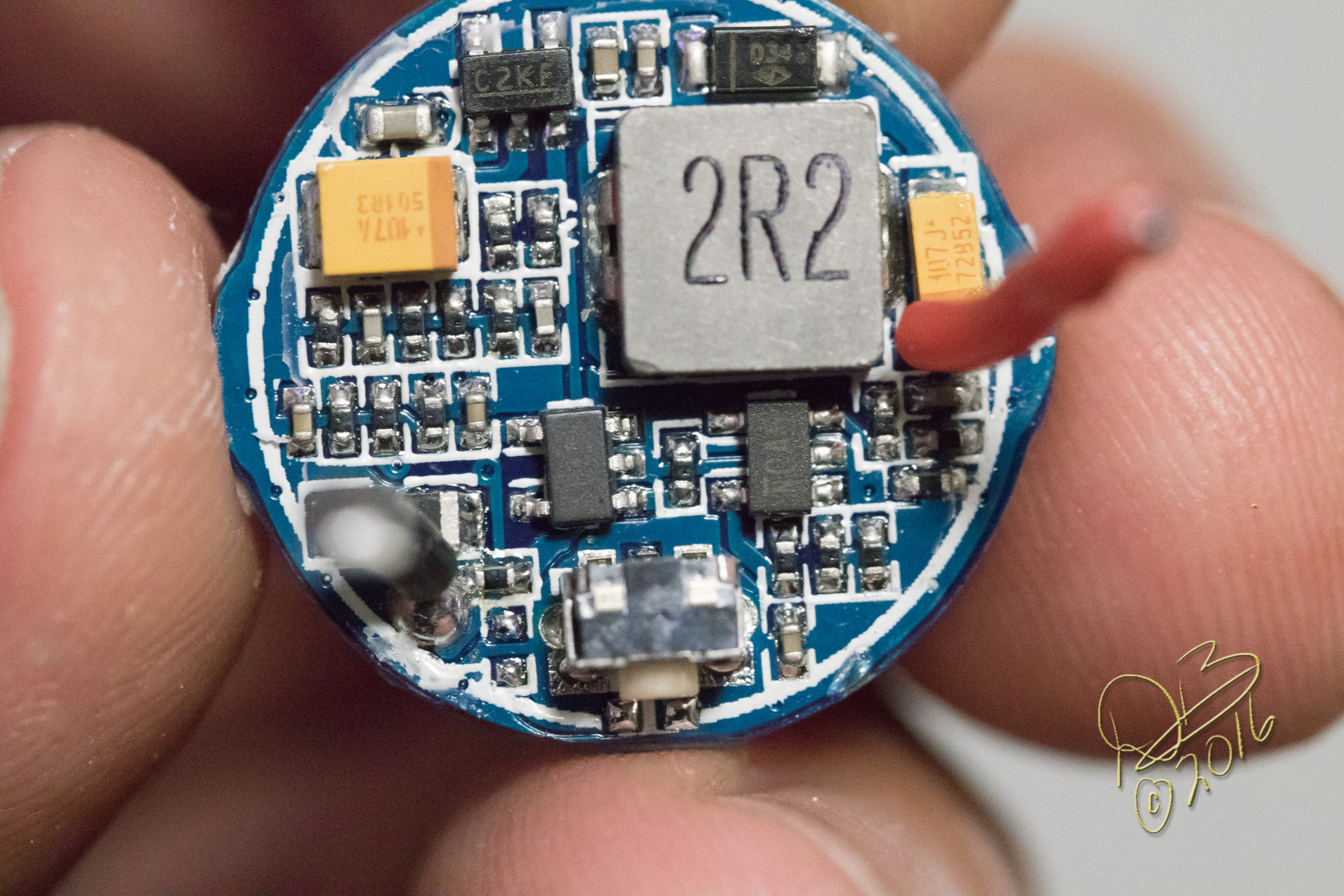

-It will have a lighted tailcap, for that I already put a 470 Ohm bleeder in the driver, but I'm out of PD68 6-led washers, ordered new ones from Oshpark :-)

But... it works, and works very well:

*On highest level 7: light output OTF 1420lm at start-up, 1250lm after 30 seconds, on a lila Efest 18350. Current at start-up is 11.5-12A, and 9A after 30 seconds. The efficiency on high is still 40lm/W which is not all that bad for a 3000K 92CRI hotrod.

*On level 3: light output OTF 40lm wit 166mA current, efficiency 60lm/W (my most efficient light is my Nitecore P12 neutral, on medium setting I measure 130lm/W, that is a low CRI XM-L2 reflector light with very efficient driver)

*and the light quality is warm yellow and nice, just as intended.