7.5amp? I have never seen any XM or XP emitter over 6 amps, and you got 7.5??!

I’ve gotten 6.0A to 6.3A regularly on XM-L2 T6 4C’s - reported on this many times over the last 2 years maybe, and that on a regular DMM w/heavy gauge wires. The clamp meters are always higher on FET drivers. I did do a regualr DMM reading at the tail as well and it was much lower - 6.5-6.9A, not sure off hand.

I’ve gotten over 6A with 22 AWG or 20 AWG wires as well. The T6 4C’s have had a low Vf, allowing this. This is confirmed by RMM. It’s all about the Vf…

This 32650 cell is awesome though. Think I checked a high performing 18650 and got much lower, in the 6’s on the clamp meter…. I’ll have to check/record this eve, head to head.

Since I really like the 4C tint, I’ve built a bunch of FET based 4C lights and pretty much all of them tested over 6A. I bought the XM-L2 T6 4C’s from Simon, MtnE, and maybe another source, not sure.

I wonder what I’m doing wrong/differently… is that always with the sir800dp? (or whatever the model# is, you know what I mean)

I have literally never gotten over 6amps from a FET-driven single emitter (except 219c)

Hhmm, I only use the SIR800DP now, but not always. Back in the day (dawn of FET's, comfy style), we used the "original" Vishay FET and pretty sure I'd regularly get over 6A, but that was with the early, better XM-L2's. Now, probably can't buy the high performing, low Vf XM-L2's. I suspect Simon still has the old stock of T6 4C's though, but only guessing.

Other tricks: only high performing cell charged to 4.21-4.23v. must use a clamp meter for better results -- actually more accurate results. Also must clean DMM wire ends regularly (oxide builds up) - re-solder/clean and/or use NO-OX-ID or equivalent.

I'm sure mainly the problem is the XM-L2 LED's you are using - nothing wrong with them, but the older ones were much better in high amps. Of course I'd take a U4 1C any day for max output! Beats an old U2 1A out at 1 full amp less, so best of both.

I've never gotten over 6A on a XP-L or XP-G/XP-G2 either on a straight single cell FET.

I agree with Tom, Vf is the major contributing factor and the older style XM-L2’s can get up close to 8A before frying. I’ve seen right at 2000 lumens like Tom has with the U4 1C from Richard, the one that I remember clearly was in an X6.

I NEVER clean the leads for my current test rig. Soldered up the 12ga Turnigy lead probably over 2 years ago and the ends have gold plated banana plugs on em. I don’t recall ever even wiping them down.

Good work Tom, leaving me in the dust with all that fancy ATTiny85 stuff… ![]()

Hmm, it probably is the LED’s then. I did a Supfire M6 with three XP-L HI V2 emitters, 20awg wires, four 30Q’s, and a very short loop soldered into the circuit at the tail. My clamp read 14.4A as the best I got. I can’t imagine the different FET would make a 2.5amp per LED difference.

My DMM leads are soldered into banana plugs (not gold plated) and the ends I contact to the the test surfaces just have solder blobs on them, so the solder blobs need refreshing, as well as adding NO-OX-ID in the banana plug/DMM connection helped (measurable). I’ve picked up 0.2A-0.3A just from cleaning up the ends - before/after measuring.

Been having some fun with the 85 - a lot more can be done. I’m only using bout 3500 bytes out of 8192 available. Limiting factor is I/O ports, and PWM limited to 2 I/O ports. Thinking of adding a slave MCU where there’s room (SRK, etc.) simply to get more I/O ports and PWM output capability…

What am I currently modding?

Making some additions to my DQG Tiny III triple XPL HI with FET.

Previously, I’d added an external heatsink around the head and a raised finishing washer around the button. This setup works, but had a few things I found could be improved:

- During the mod, the stock switch ceased to function propertly so I installed a replacement, but the new switch is not waterproof.

- At max power this light gets VERY hot very fast. Not surprising with 3000 lumens coming out of such a tiny light. The heatsink wraps around the bottom and sides of the head, but the top of the head where the thumb rests, including the switch didn’t have this extra layer. Result, is the button and that portion of the light would get uncomfortably hot, even while the internal components of the light and the battery still had plenty of leeway in which to function.

- To try to fix this I added a thin layer of brush-on super-glue to insulate those portions. This helped, but looked like crap and was still too thin at the button.

To address these issues, I’ve been experimenting with Sugru. Sugru is a mouldable glue. It comes out of the pack with the consistency of play dough and can easily be shaped and textured. It has a half hour working time. After that, wait 24 hours and it cures to silicone rubber. It sticks well, but is removable and tolerant of very high temperatures. Pretty good stuff for making custom switch boots.

I used Sugru to fashion a new cover with switch boot that completely encompasses the affected areas. This works quite well. I found I can run the light at max or 50% power much longer than before. The top of the head and switch no longer has any heat issues.

Adding a rubber layer to the light does limit how heat can get out. However, heat still escapes through the external heatsink around the rest of the head. When the heatsink gets too hot to touch, the light still functions perfectly and the battery is cool. Good enough for me.

This week, I plan to remove and redo all the Sugru. So far, I have only used black Sugru. I plan to mix grey Sugru to more closely match the color of the rest of the light, and only use black Sugru for the switch boot.

Wow, interesting bout Sugru - got a couple lights with a missing boot on the side switch - didn’t know how to attempt a fix because nothing off-the-shelf fits. I’ll check it out.

Yeah. Sugru isn’t cheap, but it does work well.

For color-matching with the grey body parts I decided to just mix black and white Sugru. I should be able to get a more exact color match if I also mixed in a tiny bit of blue and yellow Sugru to get a very slight greenish tint, but for cost reasons I decided to not do that.

The individual use packets of Sugru cost around $4 each. If I mix 4 of them it would be $16… and I’d have to make sure to get everything right on the first try with no need for touchup.

On the upside, Sugru does allow the flashlight modder to make custom switch boots and flashlight grips with relatively little effort and no special equipment.

Wow that Sugru stuff sounds great.

Firelight2 do you have any photos of it in use?? Build thread ??

Except that the 84 is bigger in sizes, are there any reasons people don’t consider 84?

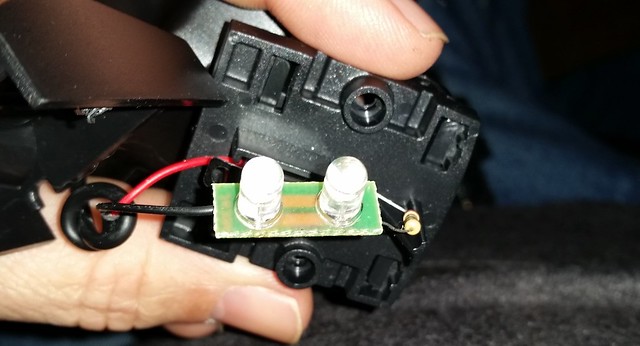

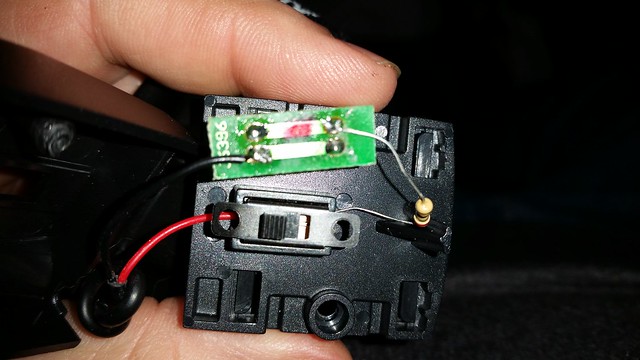

Worked over my cheap little magnified head light. It had ice cold 5mm LEDs and gave me a headache if I used it for very long. A member here supplied me a couple of hi CRI 5mm LEDs and I swapped them out tonight. It is so much better now! ![]()

!

I did my first mod the other day ![]()

A hot dedome on a LB XML clone that is in a 502B. I sliced around the dome, ran it on high without the head for a few mins and then lifted the dome off with a blade. It left a small sliver behind, but after running it on high again I managed to remove it. The colour is much nicer although it has a slight hint of green, unfortunately the hot spot is slightly out if focus.

The original plan was to use the LB as an experiment then replace the emitter and driver but the threads are of such poor quality I don’t think I will bother.

Think someone did do work with the 84 a while back, not sure. No flashlight board designs available I’m aware of - I don’t know Eagle. Would be interesting to look at, but if we go the 84 route, could also go the PIC route - think better MCU’s, more pins, not sure though. We also have some published PIC source code, but not sure if in C - I’d hate to go back to ASM.

It took about 7 hours of frantic paced modeling, even with the parallel version as a reference model, but I finished the 3S version of my AA holder design. What can I say… I tend to draw in wireframe line by line so it takes me a while. (parallel version in post #258) The center rod just acts as a stop to help with insertion of the cells and will be made from tool steel “drill rod” for rigidity. The design concept was to make a holder by sandwiching thinly machined components together.

Wow that Sugru stuff sounds great.

Firelight2 do you have any photos of it in use?? Build thread ??

I used some sugru on my B158 build to hide beam ring artefacts…

It’s a really nice material to work with, but it takes a bit of practice to get it perfect ![]()

Posted these results over here as well, post #4: http://budgetlightforum.com/comment/909908

Last night I re-tested/recorded the fully modded BLF SD10 (Lumintop) with a FET+1 driver. I took off the protection circuit from a TrustFire 32650 and got incredible results with it! All measurements done with a clamp meter at the tail w/heavy gauge wire loop:

TF 32650 @4.09v: 6.67A

SAM 30Q #2 @4.21v: 6.60A

SAM 30Q #4 @4.20v: 6.53A

EFEST 26650 4000 #4 @4.22v: 7.03A

BASEN 26650 4500 #1 @4.22v: 6.82A

BASEN 26650 4500 #3 @4.22v: 6.93A

BASEN 26650 4500 #4 @4.22v: 6.89A

TF 32650 @4.22v: 7.58A

The "unprotected" TrustFire 32650 must have incredible IMR power to beat those other cells, and it beat them significantly.

With the stock XM-L2 U2 3C on a 20 mm Noctigon, and the unprotected TF 32650 @4.22v, I got:

lumens: 1734 @start, 1578 @30 secs, 43 kcd (415 meters)

Sounds like I need to find reason to use one of those 32650 cells…

Are there any other single-32650 lights out there? I sold my SD10. Maybe I’m due for a Mag-mod