I’m digging this up again as a possibly ill suited and certainly more difficult alternative to the Zener mod. Actually, Drjones suggested using either a Zener and resistor or a voltage regulator in Post 14 and of course I had to choose the more difficult of the two. I got it working up to 3s LEDs-3s cells but never used it because of the loss of low voltage protection. That deficiency has hopefully now been addressed with an additional 28.7k resistor in series with the 19.1k R1.

There’s not much point in reading this entire thread unless you’re a glutton for punishment and I’m only bringing it back for a sense of completion. I’ll be adding final info and pics at the end of the thread and linking them in the op to make them easier to locate later.

Updates located at last post

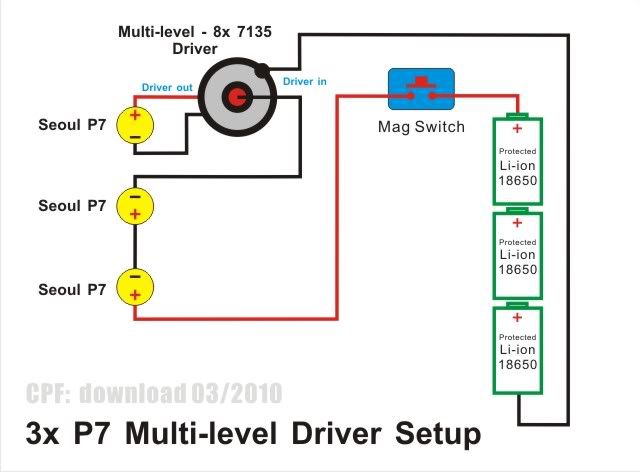

I’ve been toying with various combinations of 7135 based drivers for use with multiple led lights. There are a number of creative ways to accomplish this out there and I think I may have another possibility that takes advantage of the fact that these drivers are basically two circuit paths on the same board.

The enabling circuit path flows from the battery to the positive terminal on the driver and through the processor (if there is one) and on to the Vdd pin on the 7135 chip and through the chip to ground. The part of the circuit from the input terminal to the ground ring carries very little current but must handle the full battery voltage.

The drive circuit path also flows from the battery to the positive terminal but then leaves the board and flows through the Led then back to the board and through the 7135 chips to ground.

If you hold the chip with the long terminal at the top, Vdd will be at the right on the bottom edge and the pin on the left end is connected to Led -. The middle pin is another ground and often not soldered to the board.

For me, the downsides of running Leds in parallel with stacked boards are:

- Higher currents than the wiring for my bike lights can handle(6 A for a quad xpg).

- Multiple driver boards and/or extra wires in small spaces.

- Limitations on battery pack configurations.

- Leds in parallel are susceptible to thermal runaway.

These boards are being used by many of us without problems. This post is just to try to expand the range of possibilities. None of the above shortcomings are insurmountable.

My thought was to expand on the separation of the circuits using some of the notions put forward by others as well as my own.

To begin with, run battery + to the leds and wire them in series and then to the led – terminal on the board(4 × 7135 for xpg, 8 × 7135 for xml) and use one liion or 3 nimh in series for each led. In this current path the 7135 chips have only to burn off the excess Vbatt above Vf. For 4 xml with a Vf of ~ 3.3V each and 4 Li-ion that would be 4 × 4.2V = 16.8V with fresh batteries – 4 × 3.3V = 13.2 V = 3.4V excess.

Others have used leds in series with the driver input to lower the voltage to the enabling circuit path. I propose instead to replace the reverse polarity diode with a resistor that drops the input voltage from Vbatt down to ~ 5V. The current in this part of the board is so low that a 1/10W surface mount resistor would both fit in the same space and be easily able to handle the excess voltage. The switch is wired into this part of the circuit and need only handle a few mA.

Unless I have missed something (entirely likely), this should work and provide another option for these nifty little boards.

Where I would appreciate some input is in obtaining accurate current measurements for the enabling circuit. This is necessary in order to guage the correct size for the resistor. I would guess that since the 7135 chips are in parallel then the current through processor is dependent on the number of chips in use. Since the current in the circuit determines the voltage drop across the resistor, this becomes need to know. I made up a test bed to collect this reading but either my meter was not up to the task or I was doing something else wrong.

Here is a description of my test bed.

1- 26650

1- xml stuck to a copper cap with fujick

1- 4 × 7135 single mode board

1- 4 × 7135 multi-mode board

1- switch

1- meter

Battery + goes to both led + and switch

Battery – goes to ground of both boards

Led – goes to led – of single mode board

Switch goes to meter

Meter goes to multi-mode board

Switch off – meter reads 0 on all scales

Switch on – meter reads 15 microA but no light

Meter removed – switch behaves normally with access to all modes

For the test I used two boards to emphasize the separate circuits but only one should be needed . I might try again with the meter between the two boards. It’s possible that a clamp meter might help for this measurement.

The idea is to be able to use a single board to drive multiple leds in series with minimal extra wiring and low current through the switch.

What do you think?

*

While I am waiting on some parts, I thought I would do some prep work on the board. It is a Dx sku 7612 16-mode board. The current plan is to relocate the 7135 chips(there will be 4 as this will be an 1.5A xpg driver) to a dedicated heat sink/ground and replace the chip closest to the led+ pad with an L78L05 voltage regulator. I will need to cut the traces leading to the input pins(other than gnd) of this chip and jumper it to Vbatt and Vin for the processor. Tonight I will be prepping the board and heat sink.