I posted this in ryansoh3's thread here on a 7G9 mod - adding more details/information here.

This was more difficult than I thought, but who knows, maybe other lights have the same problems. I was only able to slightly move it after applying heat via a heat gun, but then, still couldn't get it off. At this point, I wasn't sure if it was threaded or press fit. So, at home I tried the freezer, then heat gun - but my vise is not that good. Tried the freezer/heat gun again, but this time taped the head with Gorilla tape, hoping to get a better grip with the strap wrench -- this combo seemed to work. Was able to finally get some movement and got it off. Pics below show it right after coming apart. Unfortunately I incurred some damage to the housing where it was in the vise - 2-3 layers of gorilla tape was not enough to protect it - tore right through it. Could clean it up with some filing and maybe touch-up paint - I'm not worrying about that now.

Ok, now that the hard part is over, I cleaned up the threads from the glue crap shown in the pics - cleaned up well, threads don't appear to be damaged, easily threads back on nice, the O-ring present is undamaged. Now I realize maybe why it's glued - it tightens further down then how it was originally, meaning Crelant probably adjusts the positioning (maybe the focus?) of the reflector fitting on the plastic covering the star, around the emitter, then locks it into position by gluing it - that's a potental problem if i want to keep this unglued.

I was able to remove the brass pill fine using the drilled holes from the top - its hugh, I mean really big and heavy!! The white plastic covering the star is next - looks like the star is only 16mm, but the plastic is a hard plastic, not soft, and chips if I try prying it off - think I'll drill or dremel it on the side to make a place to pry it up from - really hope that's not glued too and have to be carefult not to crack it. Once this is off and not damaged too bad, I'm done with full access to the emitter!!

--------------------------------------------------------------------------------------------------

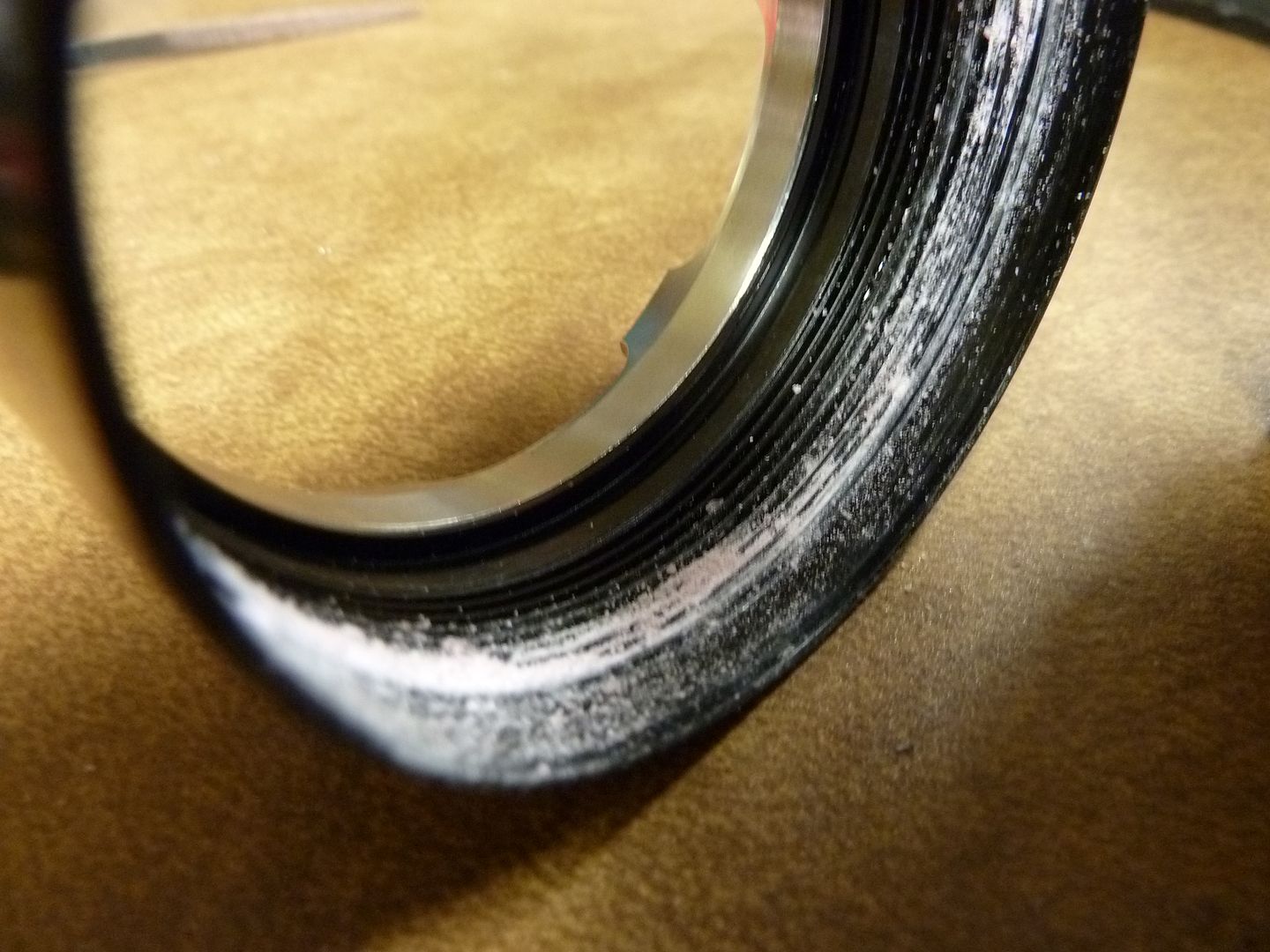

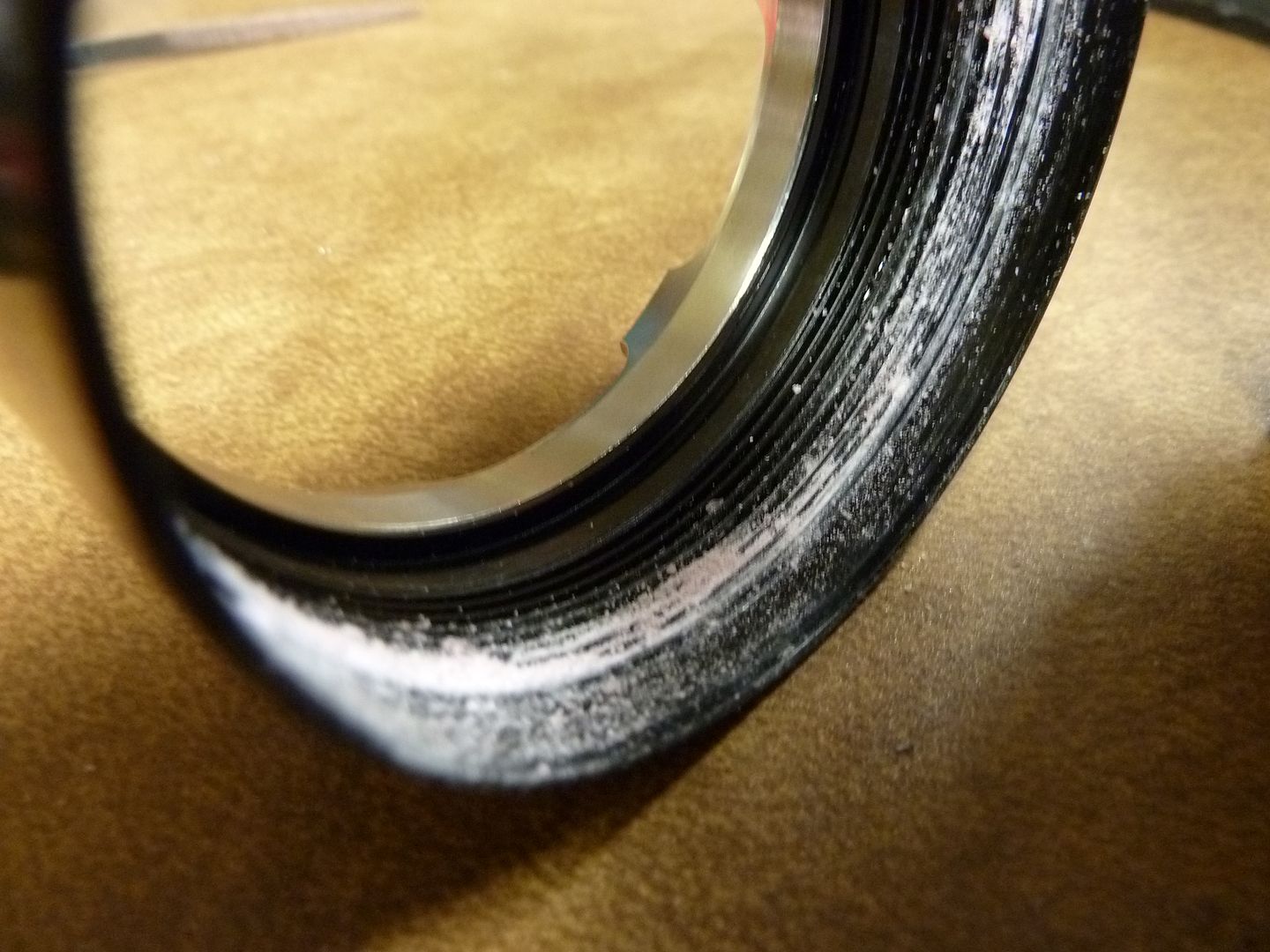

Shows the hard remains of the glue on both sizes- not sure what it is... I had no idea if this would even come apart - went into this not knowing, just saw a gap in the outer host that appears to be joint position of some sort.

Close up view of the bezel threads:

Close up view of the main body threads, abd caked up glue:

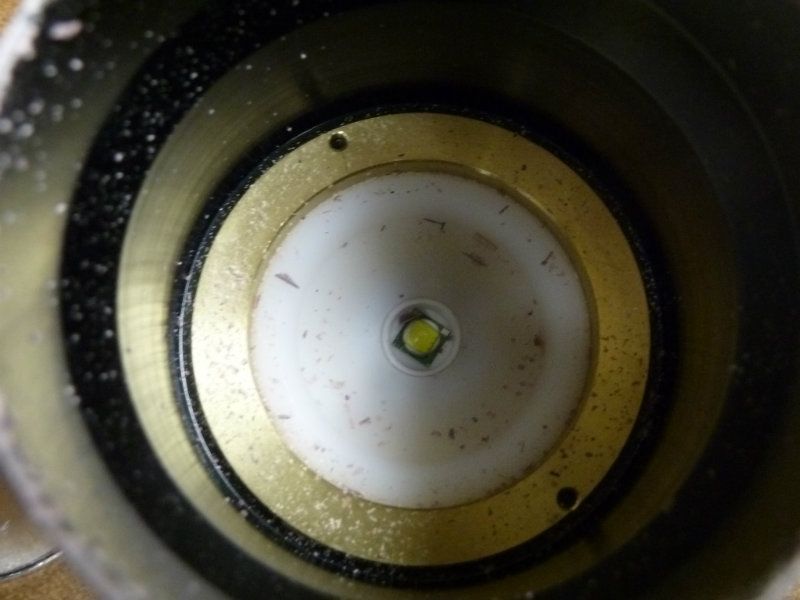

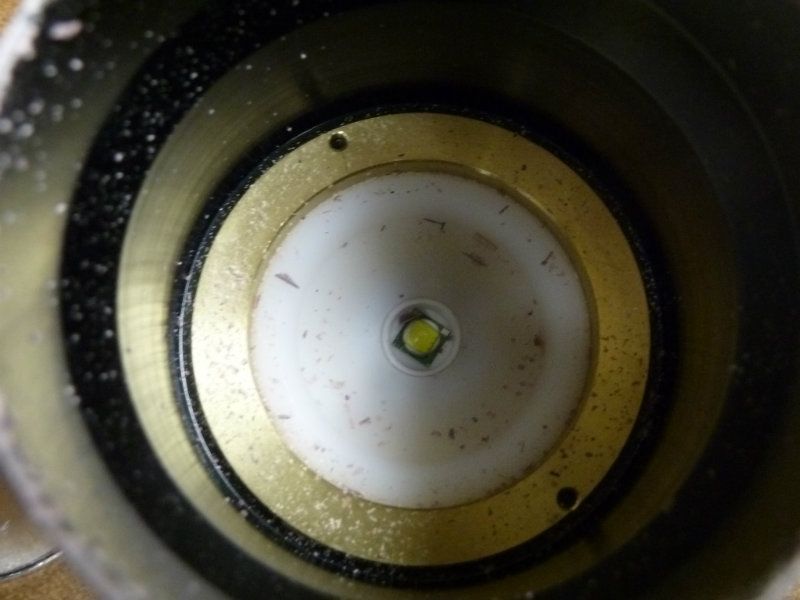

Pieces, showing the emitter/top of pill:

Close up of the emitter/top of pill. Ended up pretty easy to unscrew it using the 2 holes shown (no grease on the threads, but lots of threads, excellent contact surfaces for heat transfer):

The weapons that slain the beast:

Should have more to come...

:

: