NOTE: This light is still in progress. A few changes have been made that are not documented below yet. I will try to finish the light and update this thread as soon as possible.

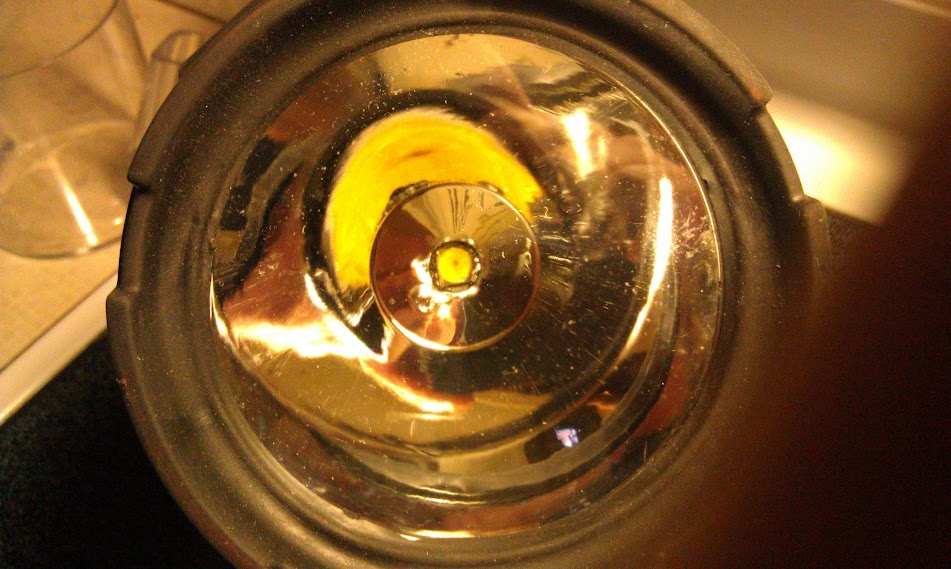

This is the second part of my journey to convert a Defiant XML Spotlight to an MT-G2 emitter with a multi-mode driver. At this point, the light is getting 250kcd. The first part is at:

Worked through the night to fabricate a “Pill” that would accomplish 3 things:

- Raise the top of the emitter to the bottom of the reflector’s interior.

- Transmit the heat from the led and driver out of the interior of the plastic housing.

- Hold the driver.

Problem with working through the night is that I get sloppier and make mistakes. Last night was no exception, but the night was a success despite some setbacks. So here we go:

I built the “Pill” out of the following:

- 3/8” copper round bar, (C110).

- ½” rigid copper tubing (typically used in plumbing).

- Pre-1982 US Penny pounded out to fit within the 3 big posts on the back of the reflector.

- Siver solder (type typically used for HVAC copper refrigerant lines).

- Electrical solder for reflowing the emitter and wiring the emitter and driver.

Using hand tools and pulling an all nighter is not advisable for a project like this. I ended up changing the design a couple times mid-stream and ended up paying for it dearly. I resoldered the emitter so many times that is started to no longer take solder. By the time I did the final solder to the emitter I was so punchy that I didn’t care much about the height interfering with the beam. I was just glad to get a connection.

I also busted the dome (it doesn’t take much as it is very big and not very sturdy. I tried to dedome with heat. I got most of the dome off. I left some silicone on the emitter directly over the led grid because I was afraid to loose phosphorous.

Ran on high for about 5 minutes. The “Pill” pulls the heat from the emitter very well. The emitter was within a degree or 2 of the surrounding copper out to about an inch each way. Then the temperature dropped along the length of the tube about 20 degrees. Max temp reached was 162 degrees Fahrenheit. I don’t want to test further until I attach aluminum heat sinks. I had the sense that the temperature had stabilized, but the pill was out of the housing in the open air.

Took the light out and was very impressed with the improvement. Tighter and more intense hotspot and fainter spill. Throws further now. Warmer tint. All welcomed changes.

Unfortunately, I lost a bunch of pictures. Hopefully, these will give a general idea:

Next step will be building a better designed “Pill” and the exterior aluminum heat sinks.