Here is part two of my comprehensive testing for output loss of flashlight hosts (part one was done on Maglites done here). Testing performed in this experiment will include light losses from components including the reflector, head, lenses, and bezels. All images can be enlarged by clicking on them.

Test equipment:

Lightbox (details here)

LX1330B Light Meter (+/- 3% claimed accuracy)

Solarforce L2 Host

Pill: XP-E2 R3 1D w/ 3-mode driver, 1.43A on high (low @ 83ma for testing)

Reflectors: Fasttech XP SMO (SKU 1208506), Fasttech XP OP (light to medium, SKU 1208509)

Lenses: Stock Solarforce Glass Lens, Kaidomain Multilayer Coated (AR) Glass Lens (SKU S008213), UCL Glass Lens, Hardcoat Acrylic Plastic Lens

Bezels:

Top row: B2 SS, B5 SS, B3 SS, B6 SS, B1 SS (SS = stainless steel)

Middle row: B2 Black, B5-style Black L2 2011, B3 L2P, B6 Black L2M 2012, L2T Black

Bottom: B2 Gunmetal

Testing Procedure/Overview:

Baseline:

First a baseline test needs to be performed so we can use it as a reference point later on when doing any comparisons and calculations. This first test will measure the light output with the pill only. I chose to use the low mode on the driver (83ma measured at the emitter) to minimize thermal related output sag. This ensures test results are consistent and repeatable due to the emitter not heating up too much. Measurements throughout the entire experiment are taken at 30s to match the ANSI FL-1 standard.

Reflectors:

After the baseline test is done reflector efficiency will then be measured. For this test and throughout the rest of the experiment Fujik Silicone Thermal Glue is applied to the threads on the reflector. This will help aid in transferring heat from the pill to the reflector. Additionally each reflector is wrapped with copper foil tape to increase the surface area for heat dispersion to the host. Each reflector will then be measured for light loss.

Head:

The head is screwed on without the moisture gasket seal and lens. Light loss caused by the head is then measured.

Gasket:

With the head screwed on the moisture gasket seal is inserted and light loss is then measured.

Lenses:

Each lens will be tested with the two different reflectors, generating ten test data results. The bezel will not be attached for each test. For the first lens test I will be using a stock lens that came from Solarforce with the factory “haze” coating.

I don’t know why it comes with this hazy/dirty coating, but it does represent what many of us receive when we buy a L2 host or head from Solarforce. After the first test each lens is thoroughly cleaned before testing so there are no specs of dust, smudges, etc. Each lens is then measured for light loss.

Bezels:

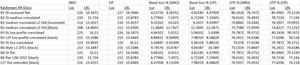

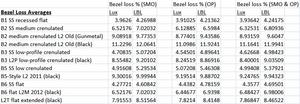

Each bezel will be tested for light loss with all four lenses and the two different reflectors. With eleven bezels to test this will generate eighty-eight data results; a considerable amount. Averages for bezel loss will be calculated. OTF percentages will also be shown for the various combinations of components tested.

Testing Results:

The units in the table are given in both Lux values measured by my light meter as well as LBL (Lightbox Lumen) values. There is a small difference in the Lux vs LBL percentages so I decided to include both for completeness.

Calculations:

Reflector Efficiency: Pill with Reflector without head / baseline

Head Loss: Reflector Efficiency - (Head with no lens and gasket / baseline)

Lens Efficiency: Head with gasket and lens / Head with gasket and no lens

Bezel Loss: (1 – (Bezel output / Lens output with no bezel)) X 100

OTF: (Bezel output / Baseline) X 100

Reflector, Head, and Gasket test results

Bezel and OTF test results (all data, large table)

If the text in the above table is too small here are the results broken down by Lens type.

Stock Lens

Data Analysis & Thoughts:

Baseline:

What is typically called emitter lumens (aka bulb lumens) is what was measured in this step of the experiment. This result is the basis for all the calculations.

Reflector Efficiency:

There are no big surprises here as far as the numbers go. Some of the light doesn’t get reflected off the reflector and simply hits the inside walls of the lightbox immediately. At this point in the experiment there are no measureable differences in output between SMO and OP reflectors.

Head Loss:

I was expecting this number to be constant but the spread is within reason. This could be attributed to the slightly different surface coating/finish of the reflectors.

Gasket Loss:

There was zero light loss from the moisture seal gasket. I was expecting a tiny bit of light loss as the gasket does have some thickness to it where light passes through the head opening. I attribute the zero light loss measurement to my light meter. On my light meter lux readings above 200 have a resolution down to a single whole number (e.g. 1). Readings below 200 lux can have a resolution down to a tenth of whole number (e.g. 0.1). If there is any light loss from the gasket it is insignificant as it is less than 1 lux.

Stock Glass Lens:

The stock glass lens straight from the factory is abysmal in terms of optical performance compared to the others. Cleaning the lens does make a measureable difference and is definitely recommended. After cleaning the lens it is still in the back of the pack in terms of optical performance, but not nearly as bad compared to the lens being dirty.

Kaidomain AR Glass Lens:

The Kaidomain glass lens with its anti-reflective coatings does very well in terms of optical performance. The anti-reflective coating on both sides of the lens helps reduce the amount of light that is reflected back into the light. Its performance easily beats the stock glass lens and is very close in performance to the UCL lens.

UCL Lens:

There is a good reason why it is called a UCL (ultra clear lens), it is simply the best as far as optical performance goes compared to the others. The anti-reflective coating on both sides of the lens helps reduce the amount of light that is reflected back into the light. The AR coating combined with the substrate material makes it a top performer. Please note that the UCL tested is not the correct size for Solarforce L2 lights. Solarforce L2 lenses are around 28mm in diameter while the UCL used in testing measured 26.82mm in diameter; a loose fit. I do not recommend using this size of lens in a Solarforce L2 as it can compromise the ability to hold an air-tight seal with the moisture gasket. The only reason the lens was tested is to compare its optical performance.

Hardcoat Acrylic Lens:

The only plastic lens tested it does perform well with performance better than the stock glass lens. While the hardcoat acrylic lens wont be a top performer in terms of optical performance, its impact resistance is superior compared to the other glass lenses. This can be quite beneficial if you are rough with your flashlight, excessive dropping onto hard surfaces, etc. The only main drawback in my opinion is the required use of specialty cleaners for plastics like Novus when cleaning the lens. Please note the size of the lens used in testing is custom from Chris at Flashlightlens.com. Any of the plastic lenses can be custom cut to the desired diameter you want. I chose a slightly wider lens diameter at 28.1mm for a snugger fit in the moisture gasket.

Bezel Loss:

Generally speaking if you use a stainless steel bezel you will have more light OTF. Colored bezels (especially black colored) reduce the amount of light OTF considerably more compared to the stainless steel bezels. Stainless steel bezels help reflect some light while the colored bezels tend to absorb light (that is lost). Bezel size also determines how much light is lost. The lower profile bezels loose less light OTF as they don’t block as much light compared to bezels that are longer and protrude further out.

General Reflector Comparison:

Following a similar pattern in my Maglite testing orange peel reflectors had higher OTF numbers compared to smooth reflectors. This is surprising as it is generally believed/perceived that orange peel reflectors should have less output compared to smooth reflectors. It is believed that orange peel reflectors have a greater tendency to trap light in the texture of the orange peel surface compared to a smooth reflector. My testing and the numbers behind it say otherwise when it comes to the orange peel vs smooth reflector comparison.

Emitter vs OTF Percentage:

There wasn’t a huge spread in terms of OTF percentage. Different combinations of components will obviously yield different results. Bezel choice has a greater impact on OTF numbers, followed by the type of lens used.

Conclusion:

After lots of testing of various combinations of components we can see some definitive trends as far as how output is affected. My results are consistent but I will not claim absolute accuracy. Please also remember there will always be sample variance. The results obtained in this experiment should not be interpreted as a basis or used to make generalizations for other flashlights. A different flashlight setup would most likely result in different results. So there you have it. If you have ever wondered how various components affect output for a Solarforce L2 series flashlight you now have your answer.

. So thanks again for the measurements !!

. So thanks again for the measurements !!