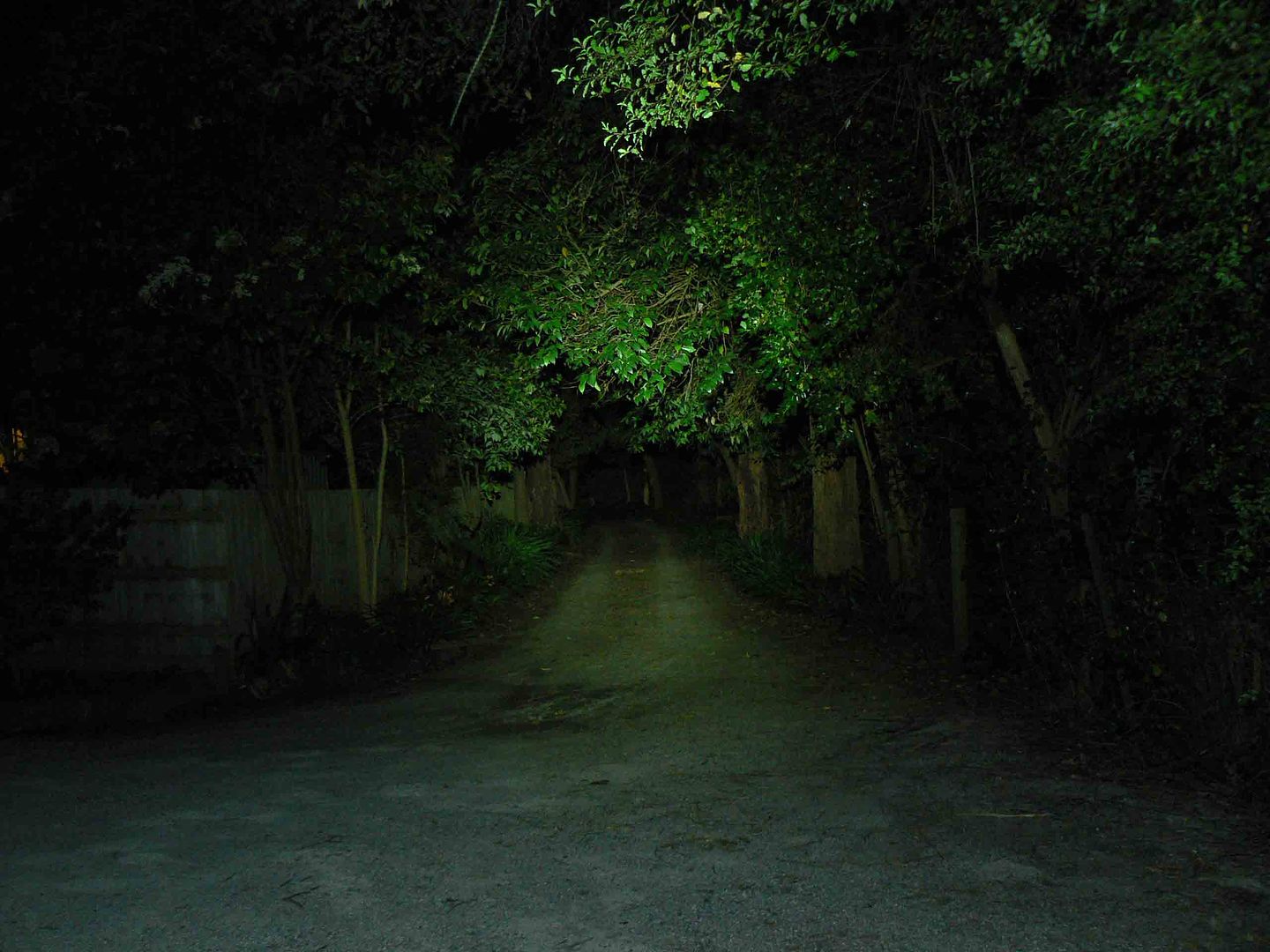

After the disappointment of the DST 9 amp light, which has been very happy running at 5 amps, I decided to build a light from the ground up with the sole intention of having a flashlight running the MTG-2 led reliably at 9 amps. This is a work in progress so I don't know if I've achieved my wish or busted. Already I have had one component busted, my lathe. I'll explain later. To date all the machine work has been completed and all components are in my hot little hands except the three 32650 batteries from FT. The only thing really stopping this light working is some soldering. I'm not sure how to tackle it yet. Lets get into it.

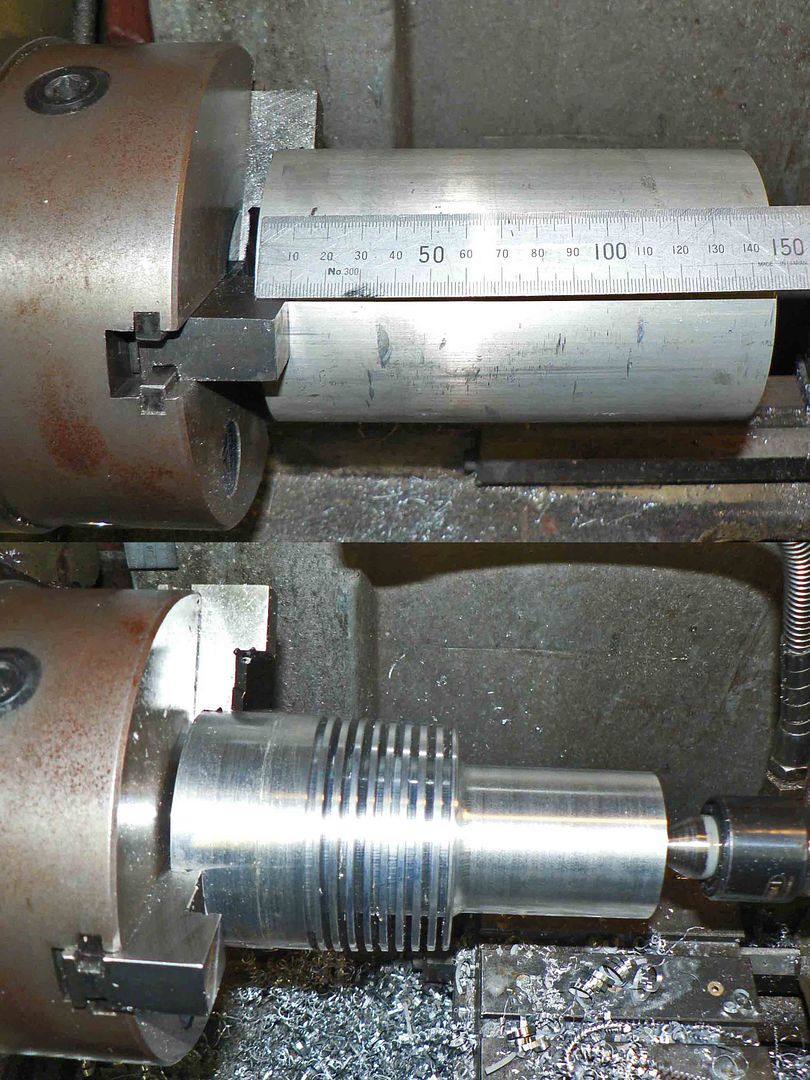

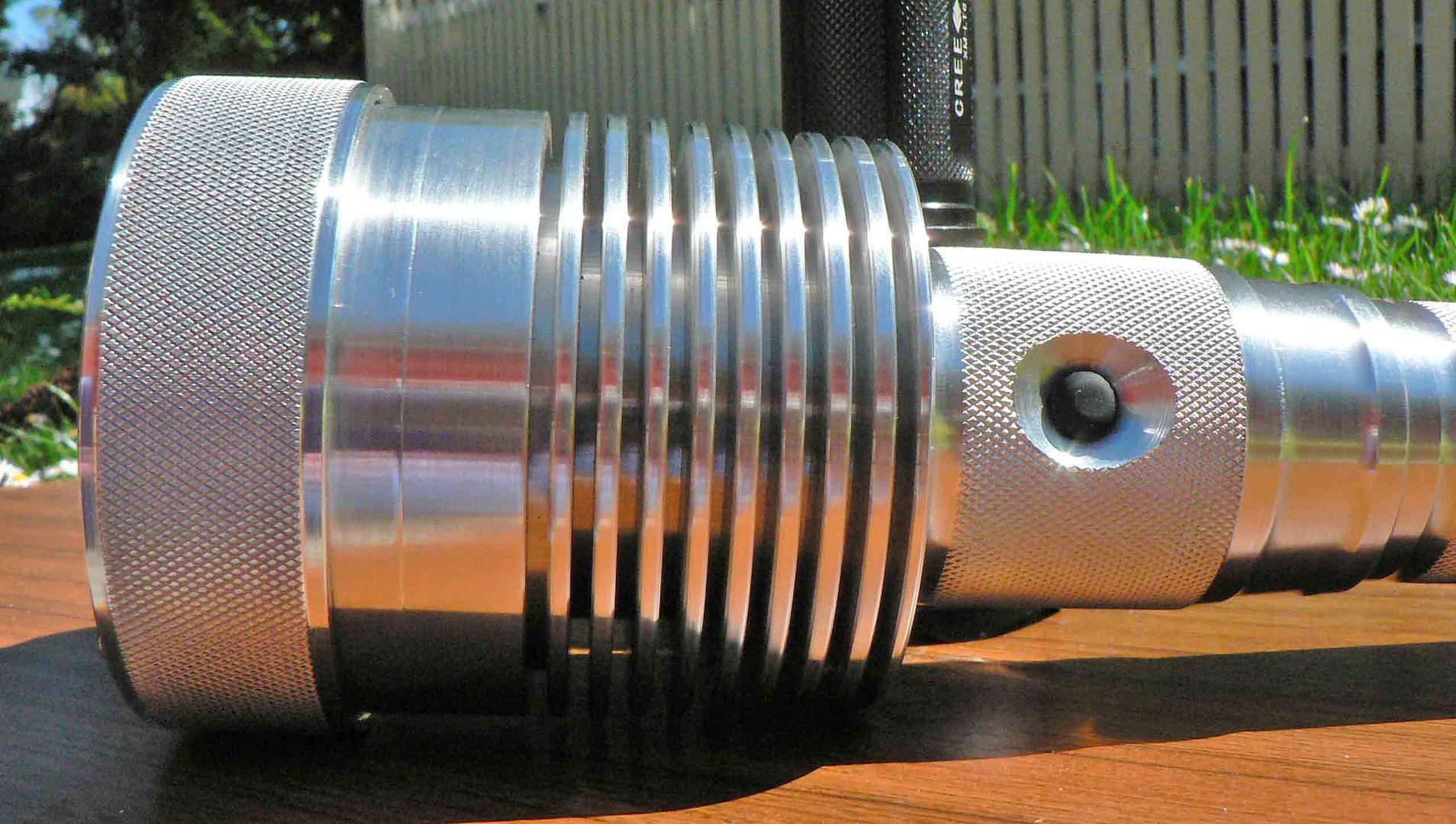

I purchased a lump of aluminium which started life 90mm round x 150mm long. It took a couple of weekends to machine this down to size due to slipping V belts and lack of rigidity but we eventually got there. The 150mm was kept as long as possible while the outside diameter ended up at 80mm to suit the lens.

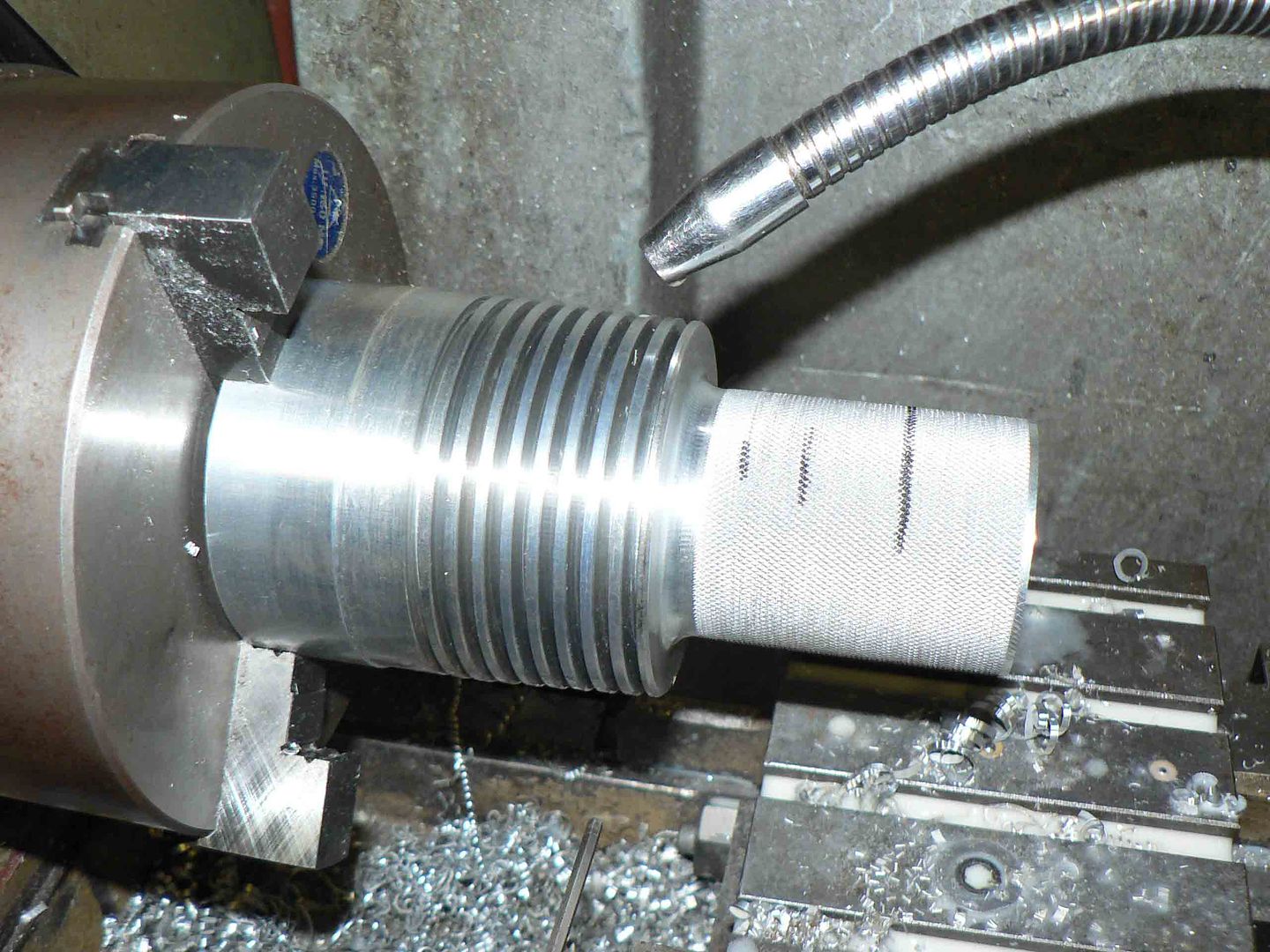

Knurling is really tough on my lathe as it just is not rigid enough. The following knurl resulted in the picture below it.

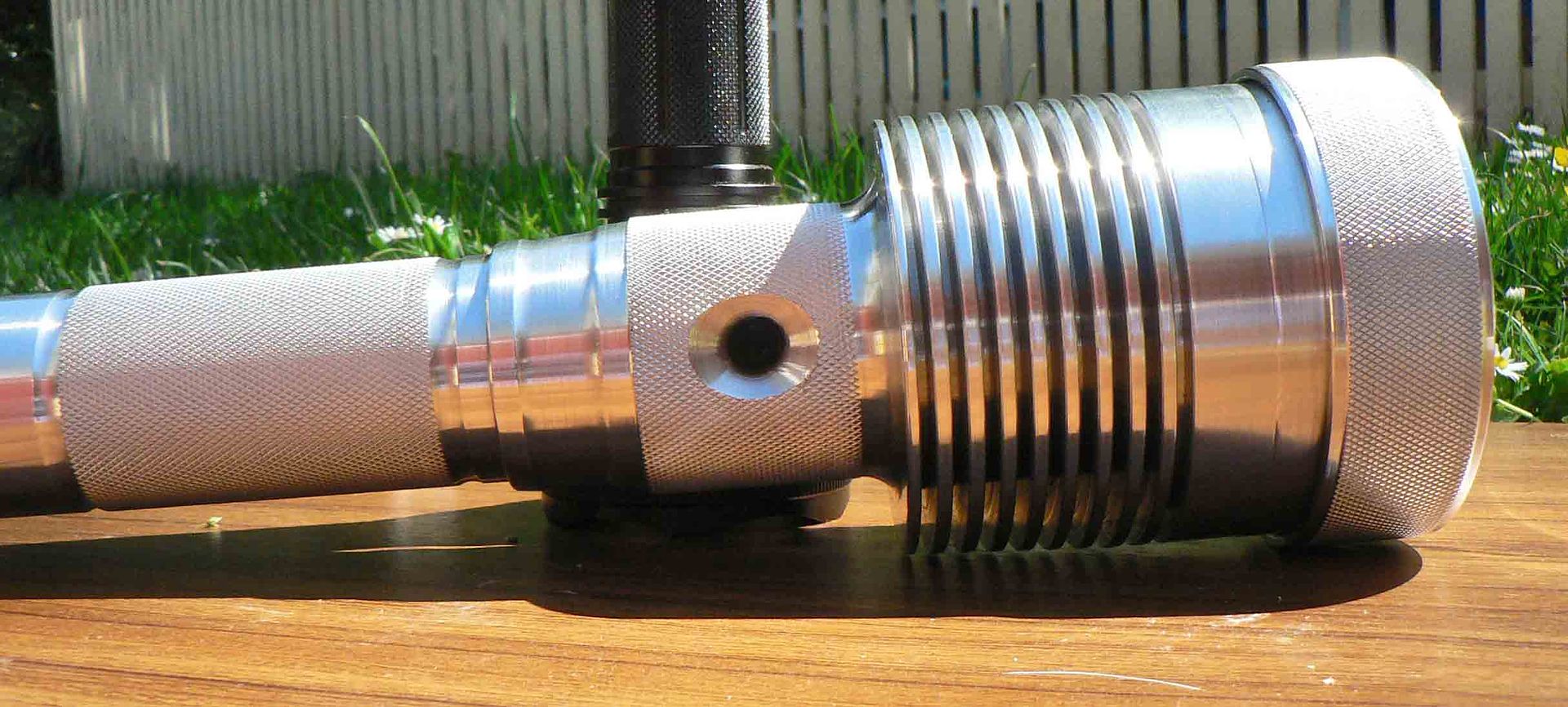

Looking from the reflector end of the housing you can sort of see the inside machined to fit the reflector and pill. The pill threads in from this side while the usable diameter of the reflector is 68mm. I will include links and pictures of the other components at a later date.

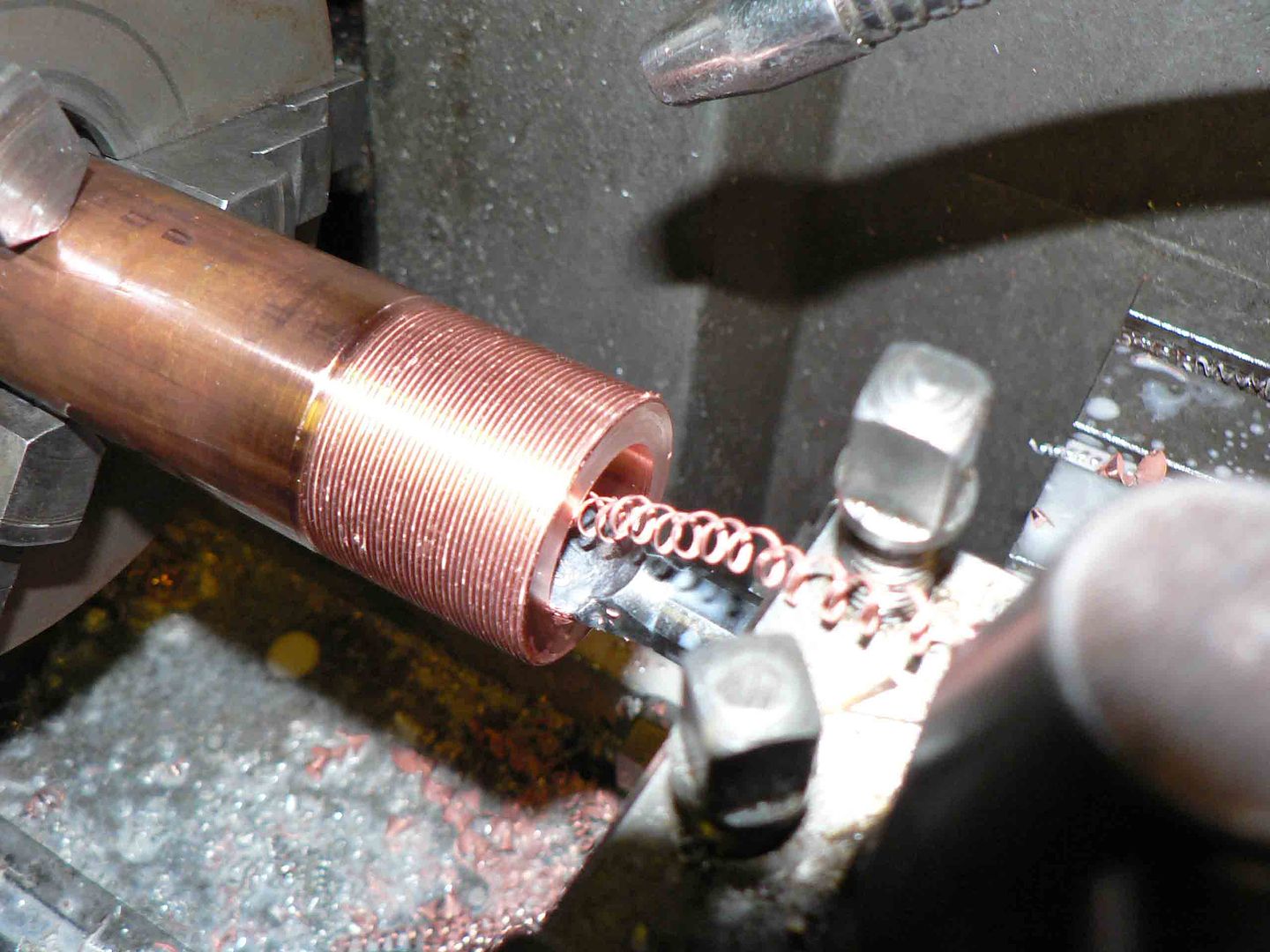

The pill did not get of to a very good start as the thread picked up big time when it was nearly onsize and a 1/8'' drill bit decided to break of in it. Its not coming out either. The thread cleaned up reasonably well but looks terrible on the macro shots.

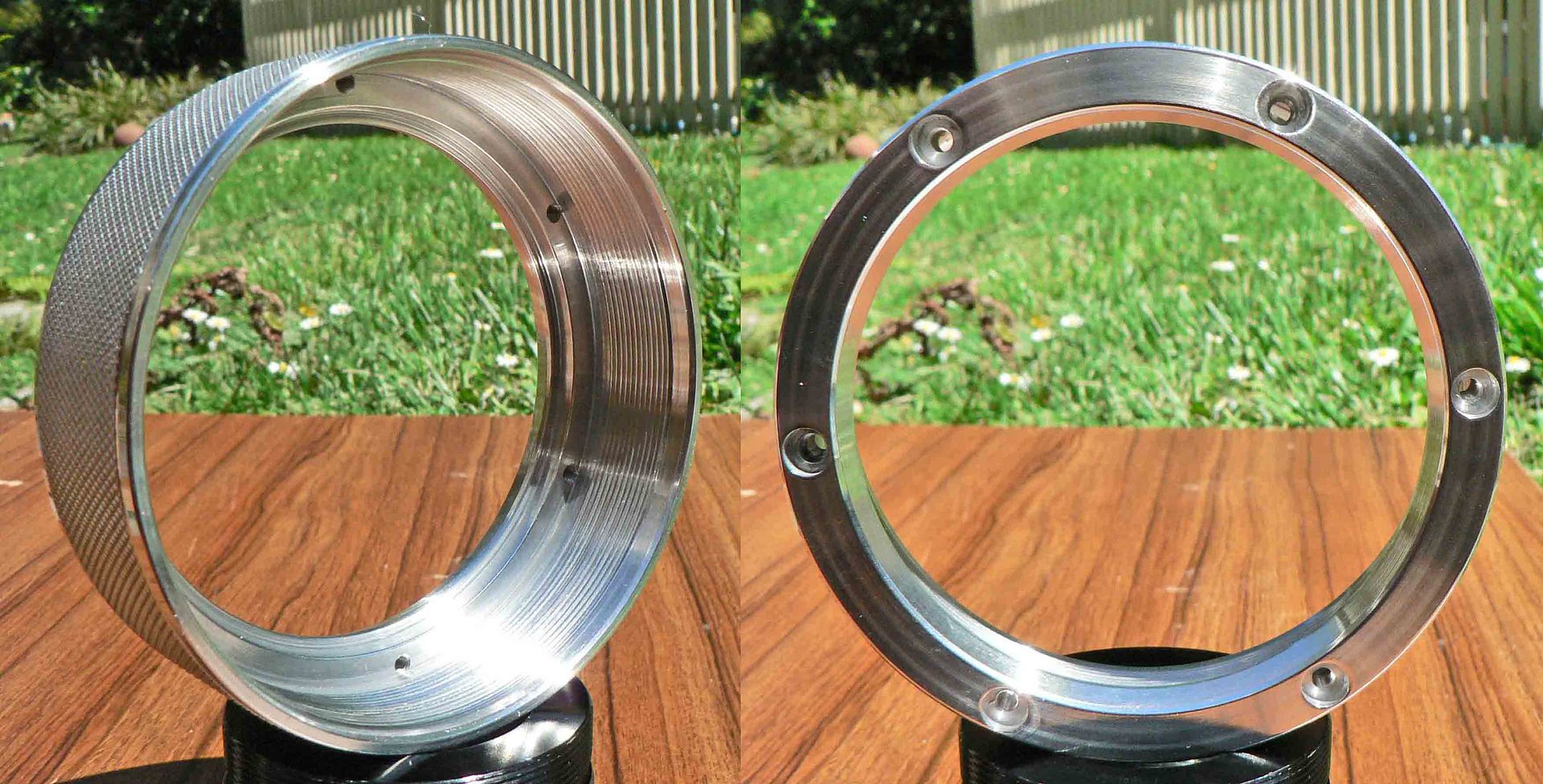

The bezel was machined from an offcut of aluminium bar.

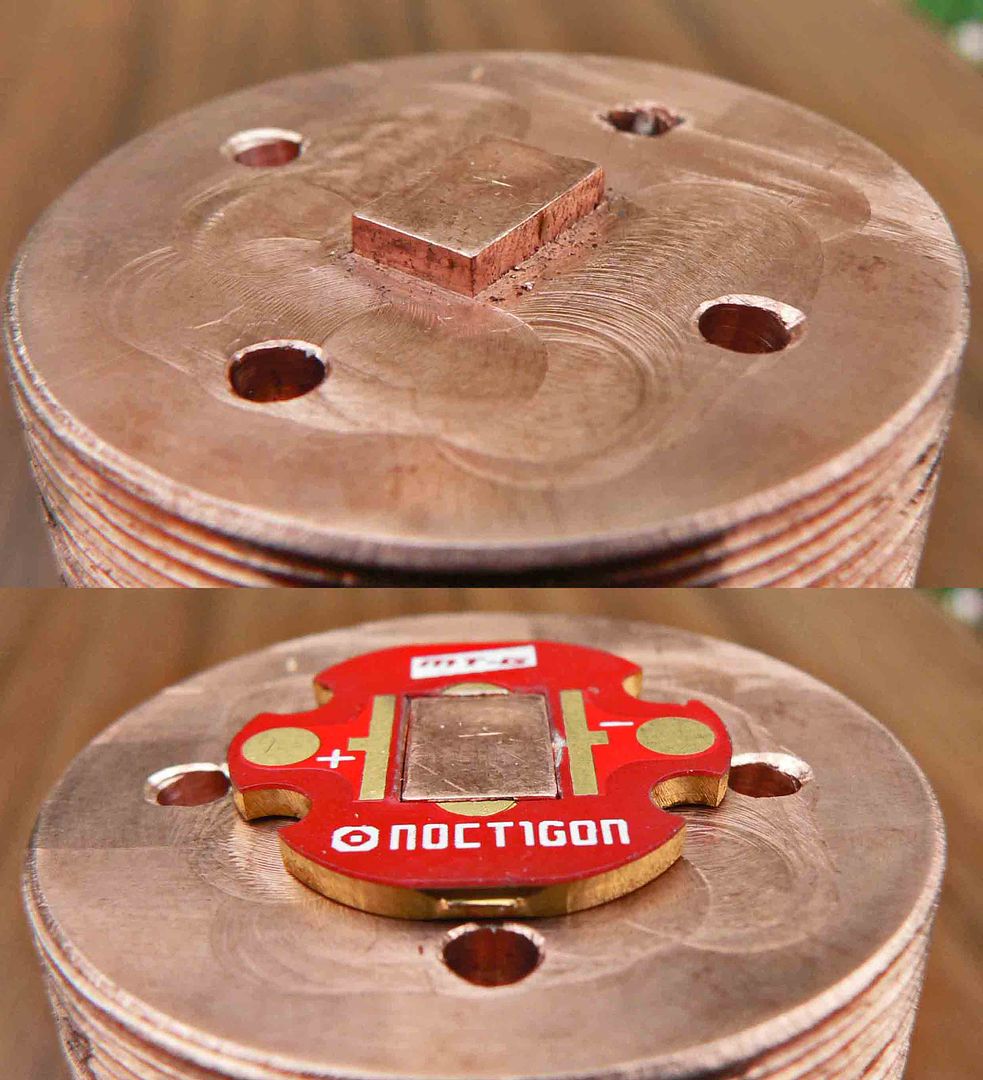

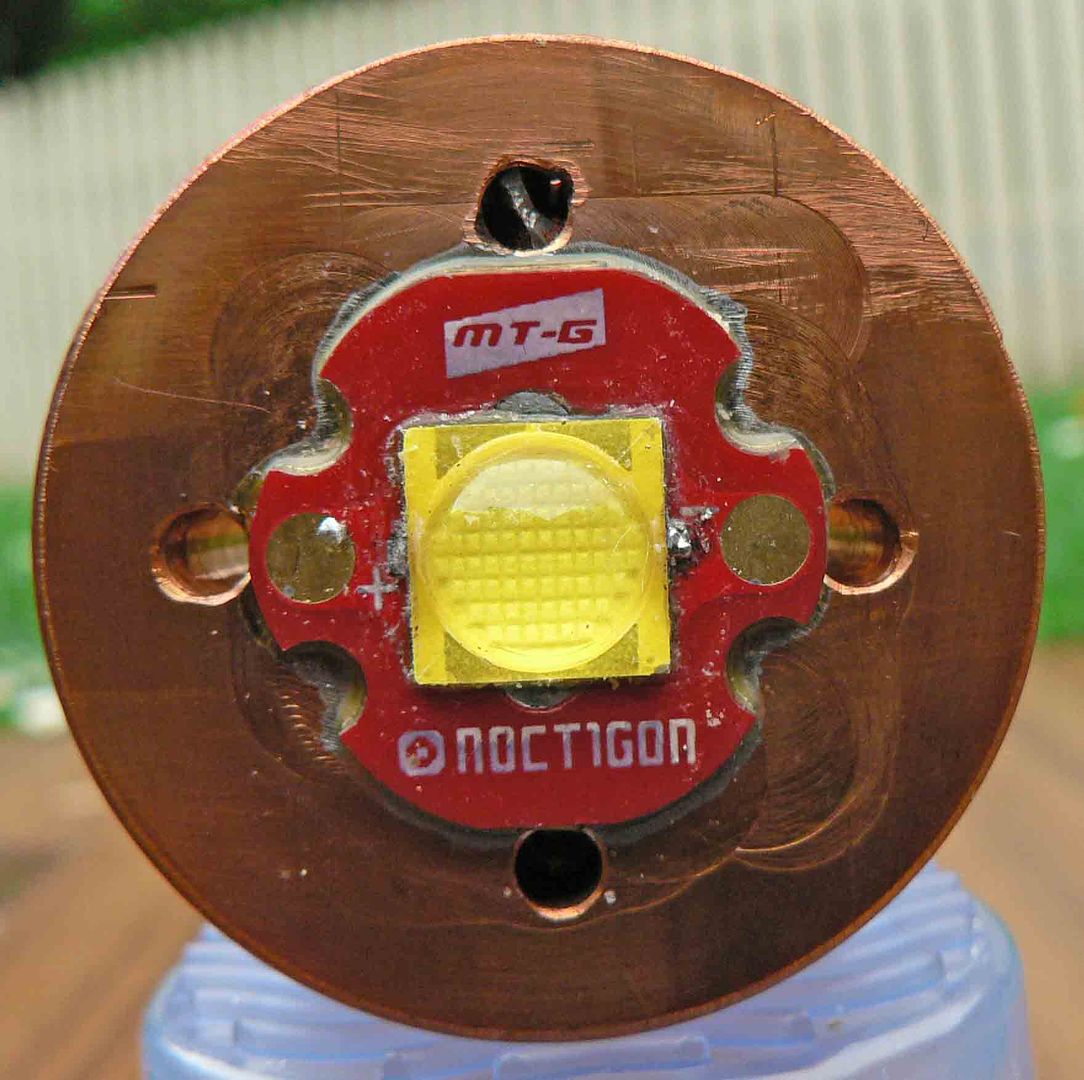

Madness had by now set in as even though I had copper stars I wanted the led mounted directly to the copper pill. On a brief test it works. Touch wood.

To make sure of a good earth from the battery to the flashlight body a 3/4'' BSP brass plug was scrounged and machined into a boss to screw into the tailcap. An o'ring is there to keep the crud out. The boss is hollowed out on the outside as this was the original hollow in the plug which has been cleaned up.

The tailcap in all its glory. The cap screws are 3mm. Diameter is 48mm.

The bezel holds the lens as its a smaller diameter than the outside diameter of the reflector with an o'ring between it and the housing. Cap screws are again 3mm.

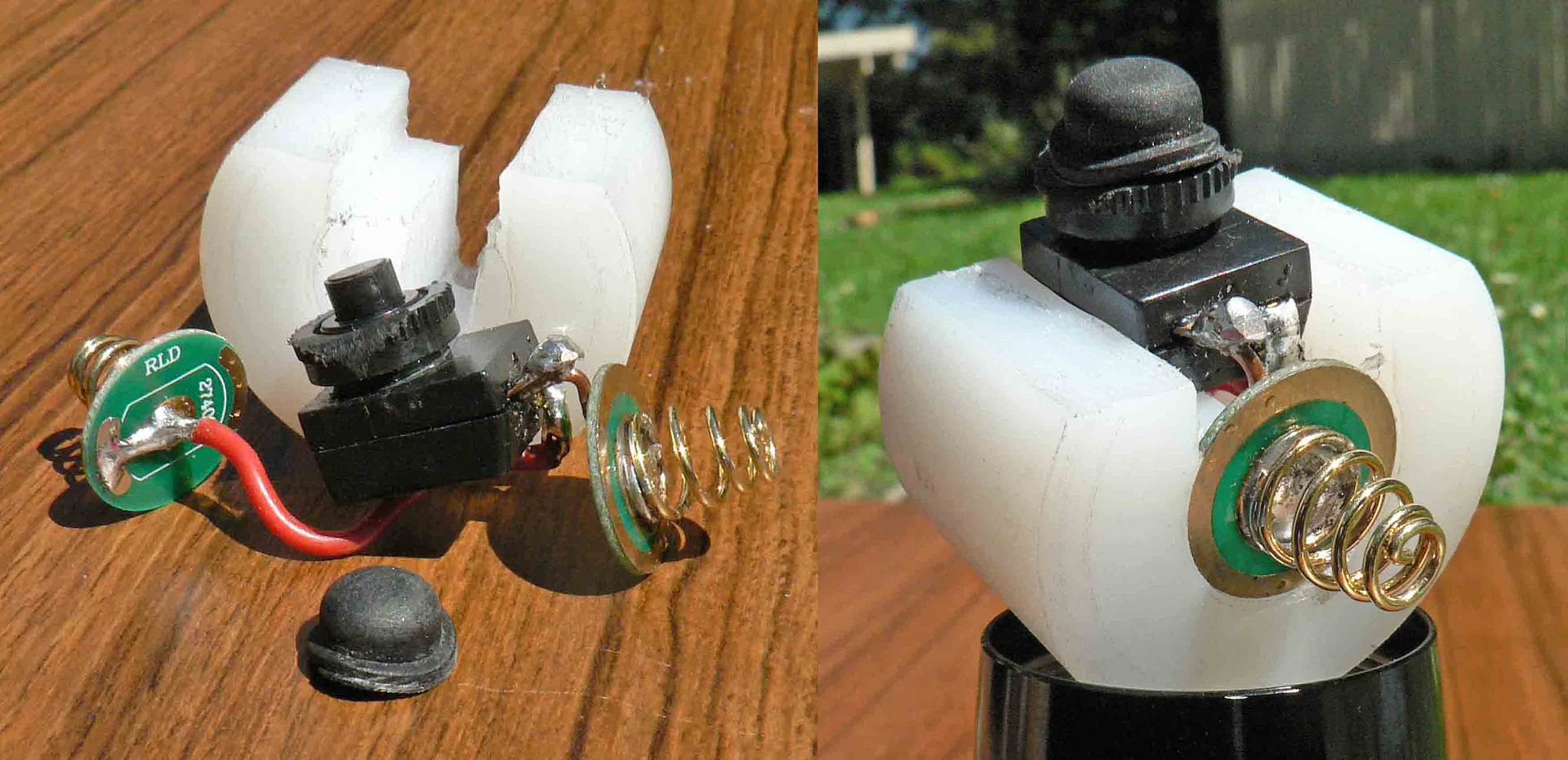

The switch was a bit of a challenge. The switch itself (thanks Mr Duck) needs to be inserted in position while the white sleeve is inserted. The board with the flexible wire attached is then pressed into its recess with the wire tucked into the groove under the switch. Its not ideal but should work ok.

The battery tube swallows the 26650 battery tube from my MTG-2 DST.

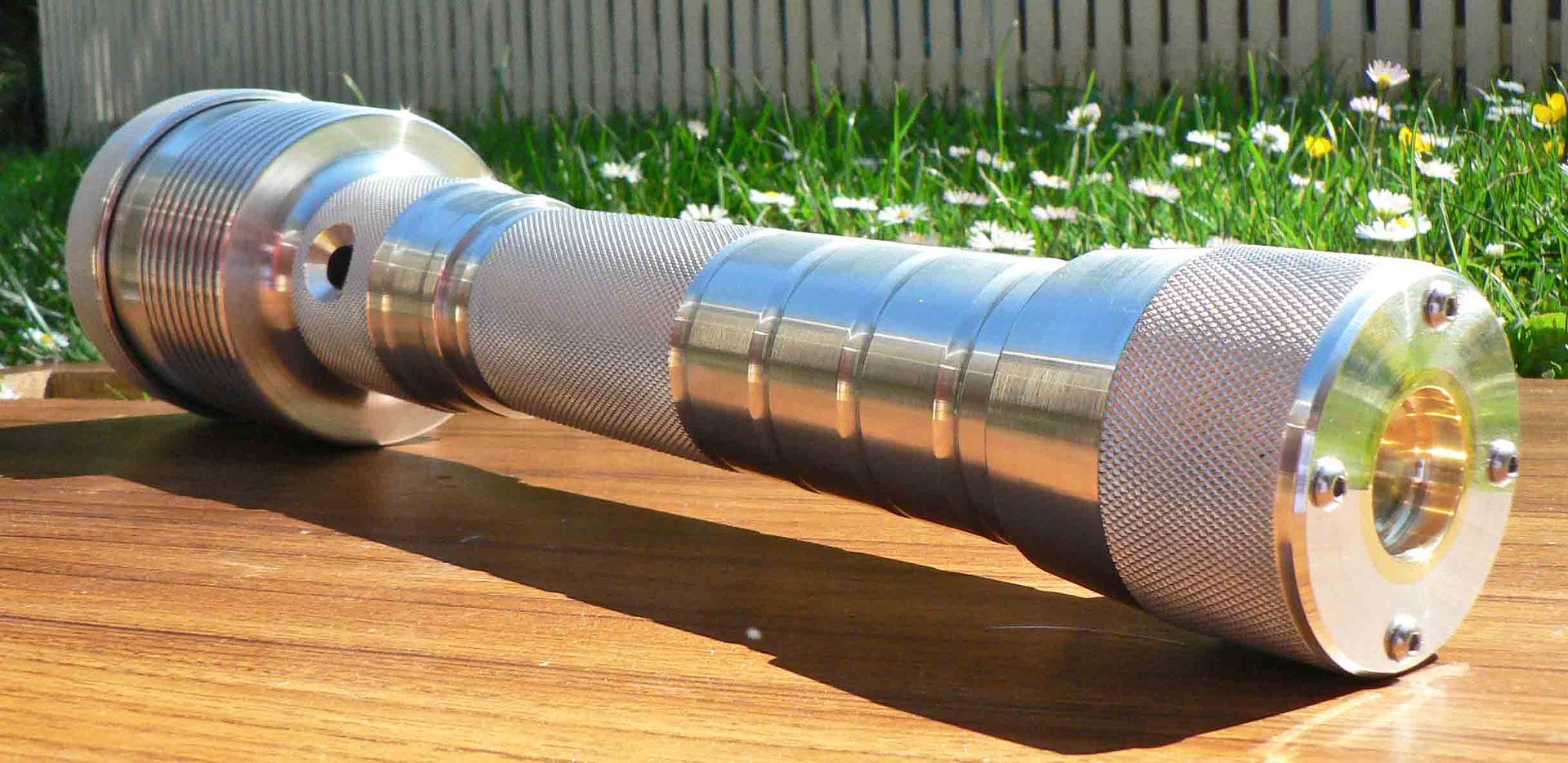

The head is pretty massive. 150mm long x 80mm in diameter. The switch area is 48mm in diameter.

The pedestal the head is leaning on is the standard defiant super thrower heatsink.

Finally a couple of pictures for comparison of the size. Left is a MagLite 3C and right is a DST 3 x 26650.

And finally, left a C12 and right a standard DST.

. I hope you get the electronics right and get the full 9 amps reliably through the led.

. I hope you get the electronics right and get the full 9 amps reliably through the led.