I guess the topic describes my latest mod pretty well.

While shopping at ant-supplies ltd. for the long-desired SolarForce T4, it came to my attention that they also had their “budget-priced flashlights” back in stock – generic 3xAAA, multi-5mm LED cluster, thin-walled aluminum tubing and an anodization not worth writing home about. Also, advertizing said that the light could be stripped somewhat, so that was a plus for me as well.

At £6.00GBP it wasn’t exactly as budget as it could have been, but it also came with a set of fresh alkalines and a neat little belt pouch, which turned out to be amazingly well-built. Not a bad deal IMHO!

So, into the shopping cart it went, and four business days later I received a package from South Wales.

The little torch performed as good as one may expect from a cheap 3xAAA light – after all, they’re just a board with some directly-driven 5mm emitters, some cells, a switch, a couple springs and O-rings. It’d have been fine as a backup lamp or something you lend out to other people, I even used it for lighting in the bathroom during a recent power outage.

The emitter board and lens were held in place with a stamped-tin lockring which was easily impaired and discarded with a small screwdriver and a pair of pliers.

I still had the old SMO reflector left over from my other mod. Its reflective layer already becoming dull and full of fingerprints, I figured it’d be a top notch candidate for a crude hackjob – and indeed, I took a hacksaw to shorten the reflector enough to make it fit into the torch head. The rough edges were milled flat on a piece of wet sanding paper, later. The pill is the fabled $16.02 Manafont XM-L T6 single-mode 4.2V dropin - I purchased a whole bulk just for toying and modding.

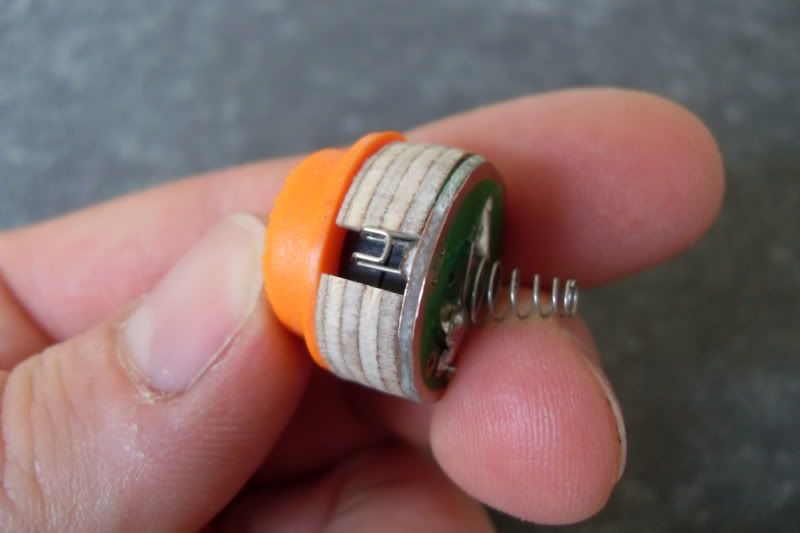

The lens came with no protection, so it received one of those super-thin orange O-rings.

Negative path to the pill is provided by scrunched-up aluminum foil. It also holds the dropin in place and dissipates heat to the head. This stuff really has 1001 uses.

Length became an issue. I hadn’t really taken any measurements before and only relied on my guesswork, and now I was missing like 2mm. So, the shortened P60 dropin proved to be two millimeters too long, and the tailcap wouldn’t completely seat with the triple AAA magazine installed. Shortening both the positive contact spring of the dropin and the negative contact spring on the tailcap clicky didn’t help much, so I ended up disassembling the tailcap and grinding off about two millimeters from the plastic ring that held the switch in place. The original tailcap spring also had to go, it was replaced by a super-soft spring I had scavenged from my Samsung ES37 pocket camera which I had killed only two days before. Lastly, the rear corners of the cell holder had to be chamfered so it would fit into the recess of the tailcap.

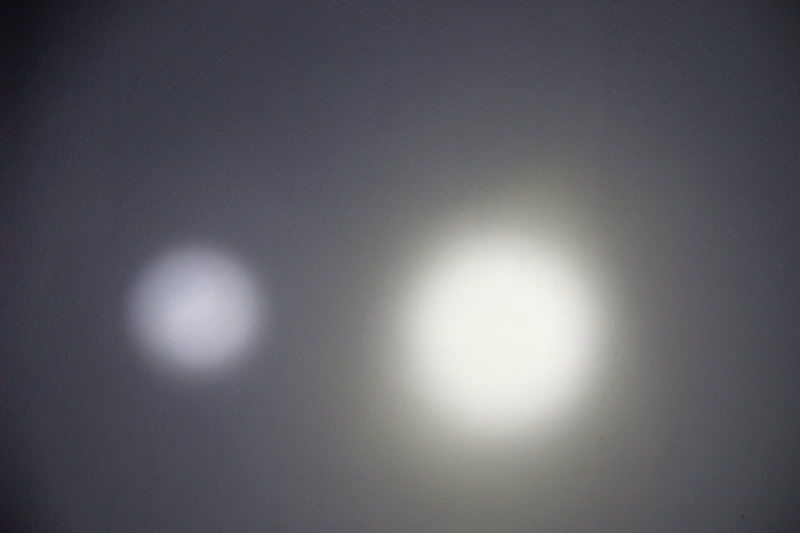

Poor wall shots substitute proper beamshots – but you’ll get the picture. Left is my current EDC light, a mini@mag housing a terraLUX TLE-5 EX cree XR-E R2 @ 700mA, right one is the new hackjob. I forgot to measure amperage, but it’ll be in the ballpark of that other light I did some time ago. I guess hotspot and spill could be more defined, but then again I saved the good SMO reflector from the Manafont pill and used the old, much abused and less-than-perfect SolarForce reflector instead.

Complete build cost was $25.70USD ($16.02USD for the dropin, $9.68USD for the host, GBP exchange rate as of today), build time was less than an hour, including taking pictures. Remember, this light came with a holster and batteries, and now sports a regulated XM-L T6. Not too shabby.

Those 4.2V dropins really kick butt. As long as the torch head is spaceous enough, almost any older 3XAAA light can be updated this way.

Be creative!