Note: We are in no way responsible for any stupidity that comes from reading this article, nor do we warrant that the information contained within is in any way correct or unbiased.

A Beginner's Guide to Flashaholism

Different Battery Chemistries

Lithium-Ion Batteries

Lithium-Ion batteries are rechargeable and the most popular type of battery used for high power flashlights. They are often used in flashlights because their voltage is similar to the voltage required by an LED. Li ion batteries are not typically sold at major retailers, and manufacturers will only sell them (in bulk) to battery pack manufacturers.We purchase them from various websites that have re-purposed them for flashlights

See Here for more information.

NiMH Batteries

These batteries are much safer than Lithium-Ion batteries, but they tend to have a lower capacity. Their voltage is approximately 1.2 volts (0.9 volts is dead and ~1.35-1.4 volts (resting) is fully charged). Because of their similar voltage they are often used as a direct replacement for normal alkaline batteries (e.g. AA, AAA, C, D).

They are not only safer than Lithium-ion batteries, it is almost impossible for them to fail catastrophically. Due to this they are much more commonly available and can be purchased at many stores, even Walmart. While the batteries at brick and mortar stores are ok, they are not the best and they often come with chargers that will overcharge them and over time damage the cells (so called "Dumb Chargers") because they operate on a timer feeding power into the battery regardless of how empty or full the battery is. Smart chargers are not very common but are available and are slowly becoming more widespread. These chargers detect the slight voltage drop when the battery is fully charged and terminate the charging process.

NiMH batteries tend to self-discharge quickly, this means if you charge it and let it sit it will drain itself to zero volts (typically in a few weeks to a few months). Newer NiMH are often the low self discharge variety, meaning if you charge them they drain themselves very slowly (in the order of years). These batteries are much more desirable so that when you need a flashlight you know the battery has power.

The best NiMH batteries on the market are made by Panasonic (Sanyo) and they are called Eneloops. They can be hard to find in brick and mortar stores but are slowly becoming more widespread. They come in two main varieties, the standard Eneloop version, having a capacity of approximately 2000 mAh and the Eneloop XX which has a capacity of 2500mAh (and are more expensive). The AA version can supply currents up to 10 amps and are LSD (low self discharge) cells

Eneloops come in sizes ranging from AAA to D, but are most commonly available in the US in the AA or AAA size. You can either order them online from many different retailers or purchase them at Costco, which often has exceptionally good deals at close to 2 dollars per battery.

Everything you want to know about Eneloop batteries

NiCad Batteries

NiCad batteries are a outdated type of rechargeable battery. They have a similar voltage to NiMH batteries. They have a number of problems: their ingredients are extremely poisonous, they need to be carefully treated to get maximum capacity, they typically have a much lower capacity than NiMH batteries and they also self discharge rather quickly.

Alkaline Batteries

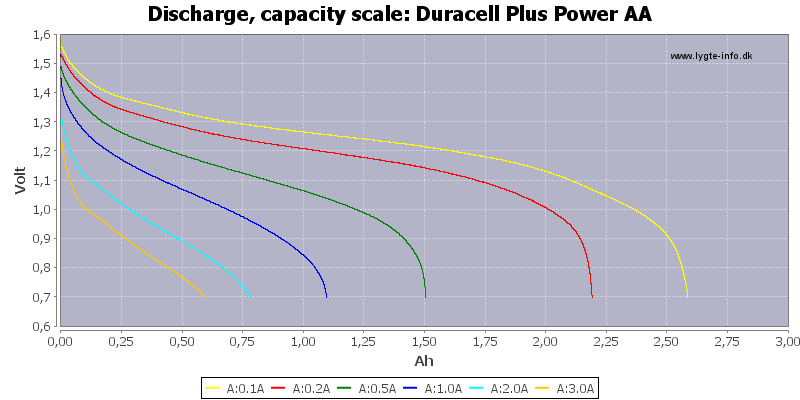

Alkaline batteries are the type that are commonly sold in stores, while they are common, they perform their best at very low current draw, and not very well at the high currents used by high power LED flashlights. They have a much lower capacity than NiMH batteries at high current draw and can only supply very small amounts of current at their rated capacity, generally maxing out in between 1 and 3 amps which will typically reduce capacity by 75% or more (XM-L(2) LEDs can be officially driven to 3A, and much higher though this is not supported by their manufacturer)

Alkalines can and will often leak, leaving corrosive ingredients inside your flashlight that can be insanely hard to remove and can destroy the light. The risk of this happening increases with time, the longer they are left in the light, the more likely the batter(ies) will leak, though some batteries don’t end up leaking at all (this is not determined by brand, for example in a pack of 4 batteries, 1 to 3 may end up leaking someday). The only way to determine if a particular battery will leak is by leaving it in the light and seeing what happens (this can take weeks, months, years). The leaked battery acid can end up causing chemical reactions that are permanent and ruin the light. For these reasons alkaline batteries are generally not favored by flashaholics except for short term use in emergencies.

Different Battery Sizes

Common battery sizes for flashlight use include AA (14500), AAA (10440), CR123, 18650, and 26650. Each size has its advantages and disadvantages, including size, weight, cost, availability, energy density etc. Many of these sizes are available in different chemistries, be they the aforementioned NiCad, alkaline, lithium ion, lithium polymer, NiMH.

AA

AA batteries are commonly available in stores, in the Alkaline chemistry.

14mm diamter 50mm length

14500 is the name of their lithium-ion variant

Available as: NiCD, NiMh, Li-Ion, Alkaline, Lithium

AAA

AAA batteries are smaller than AA batteries, and are also commonly available in stores

10mm diameter 44 mm length

10440 is the name of their lithium-ion variant

Available as: NiCD, NiMh, Li-Ion, Alkaline, Lithium

CR123

CR123 batteries can be found in stores, their voltage is around 3.2 volts

16mm diameter 34mm length

Their lithium-ion variant is called either 16340 or RCR123A

Available as: Li-Ion, Lithium

C

C size batteries can be found in stores, mostly in the Alkaline chemistry

26mm diameter 50mm length

Note: Many C batteries are actually closer to 25mm diameter than 26mm diameter

Their lithium-ion variant is called 25500, but people often attempt to use 26650 or 26500 to replace them

Available as: NiCD, NiMh, Li-Ion, Alkaline

D

D size batteries can be found in stores, mostly in the Alkaline chemistry

32mm diameter 60mm length

Their lithium-ion variant is called the 32600 but sometimes people use 32650

Available as: NiCd, NiMh, Li-ion, Alkaline

Light Output

Lumens

Lumens are a measure of the total amount of light produced by a device (flashlight, light bulb, headlight, etc). The number of lumens a device produces is measured by placing the light source in an integrating sphere (IS) so that all of the light is evenly distributed throughout the IS. A lux measurement is then taken from one point in the IS and multiplied by a conversion factor. This conversion factor can be calculated based on the inside surface area of the sphere (if the absorption rate is known), or by calibrating off of other known lumen outputs.Lumen testing is very expensive since calibrated integrating spheres are extremely costly pieces of equipment. Several BLF members have built their own integrating sphere and have calibrated them using ANSI tested lights, which is not a perfect method of calibration (because even the same binned chips can have an output difference of 5-10% and there is no way to know what end of the bin spectrum your light falls upon) but is the best available method at a reasonable price and the results should be very reproducible.

See here for more information on a custom made IS

One thing to watch out for is Chinese LumensTM, this is when chinese manufacturers over "estimate" the lumen output of their lights. An example would be when a light with a single XM-L is said to be 1600 lumens or more which is not possible. Sometimes a good rule of thumb is that chinese lumens are multiplied by 3 (an 1800 lumen light actually puts out 600 lumens) but this ratio often does not hold. Lumen exaggeration is rampant on ebay, and less reputable websites, but is still found on even the most reputable ones, especially if they are publishing manufacturer provided "specifications". Sometimes even possible lumen numbers are fake, they use cheaper circuitry so even those numbers are wrong (an XM-L may be advertised as 900 lumens which is possible but the circuitry only allows enough current for 300 lumens). See below for a rough estimate of maximum possible lumen output for each type of LED, higher than stated currents will generally produce more amps under ideal conditions (outside a flashlight in an environment that has more heat dissipating ability or a very well heatsinked flashlight).

Match has done a number of very useful lumen tests on different emitters. These can be seen here. Part 1, Direct to Copper, Part 2, Part 3, Part 4.

XM-L: 800 (3 amps, 3000 mA)

XM-L2: 900 (3 amps, 3000 mA)

XP-G: 400

XP-G2: 500

XP-E: 300

XP-E2: 400

XR-E: 200

P4: 200

P7: 700

Many companies will advertise LED lumens, or how many lumens the LED is putting out, rather than OTF lumens, or how many lumens are going out the front of the light illuminating your target. There can be as much as a 35% difference between the two. Lumens are lost in the reflector, the glass the bezel and the LED base. Anti reflective (AR) coated glass can reduce lumen losses from the glass, regular glass can have about 85-90% transmittance, real (fake AR coated lenses are rampant) AR coated lenses can have 96-98% transmittance.

The longer a light is on, the more the lumen output decreases. This is due to the LED heating up causing it to become less efficient (this is known a lumen sag). Lumen output will stabilize when the heat shedding rate matches the rate of heat generated. In order for this to happen a flashlight needs to have a good thermal path, it needs to be built with good heat transmitting materials and have many cooling fins on the body coated with a high emissivity material (typically anodizing).

Lux

One lux is technically defined as 1 lumen spread over 1 meter, it is also how we define how far away a light can throw. It is measured with a lux meter, which can be purchased from many different websites. The best way to take a lux reading is to place the lux meter 4 meters away from the light source and record the peak beam intensity. Multiply that number by 16 to get the lux@1 meter measurement. The distance it throws can be found with the formula distance=√(kcd measurement/.25). So if a light measured 1000 lux at 4 meters it would be equal to 16 kcd so it would throw approximately 253 meters.

Candlepower

Candlepower is equal to the amount of lux at 1 meter, it is shortened down to cd. kcd means thousand cd. This means that 16 kcd is equal to 16,000cd.Brightness is often stated in Lux or candlepower, meaning brightness at a single spot (for a flashlight it would be at only the bright spot in the center). Lux and candlepower can be increased by using a larger reflector (or smaller LED) and focusing more light onto a smaller spot even while the total lumens being put out does not change.

Types of Drivers

A driver is circuitry that allows the LED to function correctly, by regulating voltage, current and providing features such as different brightnesses, strobe and/or SOS ability. Many drivers also come with a low voltage warning to inform the user the battery is nearing depletion.

Linear drivers are circuitry that simply burn off any voltage over the vF of the LED as heat. This means the efficiency is determined based on the voltage input minus the voltage output (requirement of the LED) and average about 80% efficiency (18650 driving an XM-L chip) An example of this would be the popular NANJG 105C driver. Most drivers use AMC7135 chips to limit current, with many chips being used (each chip allowing 350 ma to pass through it), in parallel on the circuit to allow more current to flow to the LED. One other problem with linear drivers is that the input voltage has to be close to the output voltage or they will overheat and burn up. Efficiency of this driver depends on the difference between input voltage and LED voltage. This driver consumes no current, but about 0.1V. This driver is cost effective and simple to modify. Once the battery falls below the voltage of the LED plus driver (which typically happens after its about 20-50% drained) brightness begins to fall until the battery is empty or there is not enough voltage to power the LED. This is because at a target current the LED needs a certain voltage to operate and if it doesn't get it because the battery can't provide it, it starts drawing less current which causes it to lose brightness.

/Intl-Outdoor%20UR18650FM%202600mAh%20(Black)-Capacity.png)

This chart shows voltage under load (voltage sag) at different current levels, higher current draw means more voltage sag, for an XM-L (driven at 3A) after the voltage drops to about 3.6V under load the brightness starts falling until the battery is dead. Other LED chips will lose brightness at different voltages depending on various factors.

Buck drivers are ones that convert any voltage above the needed voltage to extra current. This means they can be much more efficient than linear drivers if designed correctly. However many of the commonly available ones are not as efficient as they could be (cheap ones can have terrible efficiency numbers, on the order of 50% efficient or less), and can’t supply very much current. They are often used to allow one to power a LED with multiple li-ion batteries in series.

Boost drivers increase the voltage to power the LED, they are used to power a LED from a low voltage power source like an AA battery. They tend to be rather inefficient (the cheap ones which are rampant can be 50% efficient or less) and can usually only supply very small amounts of current, with very few being designed to supply over 1 amp to the LED.

The most common size of driver is 17mm in diameter which allows driver swapping if you don't like the one that comes with a light or it fails (rare but it does happen). However they come in sizes ranging from 10mm to 30+mm in some lights.

Quality

The quality of a particular light tends to be best when it is first released, and each subsequent batch of lights produced may be debased in some fashion, often resulting in a light purchased a few years later which is substantially inferior in quality to one bought when the model was first released. This process is not linear and (very) few companies never pursue this debasement, while other companies pursue it with increasing fervor with each new batch of product made. Often the light will look perfectly normal, the appearance of a product is considered to be perhaps the most important feature, so it may be ready to fall apart but will still look like a million bucks and often just as good or better then the excellent quality version when it first came out. Quality this low is not often seen in flashlight construction, but has been known to happen.

This process has been referred to as quality fade, which is the result of continuous tweaks to increase profit, such as substitution of materials, use of cheaper parts, even cutting corners on worker safety or use of poisonous chemicals on the product or in its construction. This method of manufacturing is not unique to flashlights, but is found in many if not most items manufactured in china.

This process of quality fade is very well described in the following book, which is not flashlight specific

For chinese made lights this can mean cheaper anodization or even substitution of paint for anodization (rather rare), cheaper metal used in the body (flexible aluminum for example), substitution of cheaper LED output bins, knockoff LEDs which perform poorly, use of cheaper driver circuitry, no solder used between the LED and mcpcb it is soldered to (rare but several examples on BLF have been found), and hollow pill (metal that holds the LED, LED star and often the driver circuitry), the pill being needed to collect and transfer heat to the body of the flashlight for cooling purposes.

Many lights advertised with exaggerated specifications, longer runtime claimed than is possible, higher lumens or lux then the led is actually capable of (see above), priced at ‘extreme’ discount (the discounted cost is the actual price) and many other tricks to entice potential buyers.

Knockoff or fake batteries are rampant in the online world, many people have sworn off buying batteries from ebay because they very often end up with counterfeit batteries. The problem with these is that they often have far less capacity than they claim to (sometimes up to 90% less), they often can’t put out enough current to fully power the light, they likely won’t last as many recharge cycles as a genuine battery, and they have a higher failure risk than real batteries, either by not holding a charge or possible increased explosion risk. Sometimes it has even been found that a small battery has been put in a can of a larger one and sold as the larger battery. Fortunately genuine batteries are not very expensive to buy, the price difference between the fakes and real batteries is often not huge, and the extra safety and performance of genuine batteries makes buying fakes a pointless endeavour. Known sources of genuine batteries include fasttech and intl outdoor.

See here for more information

lithium polymer battery in an 18650 can with ultrafire label

Purchasing lights

Buying lights from various websites is pretty straightforward, choose which light your interested in (reviews for many budget lights can be found with the BLF search (upper left corner) or in the appropriate sub forum, and purchase with a credit card on the stores’ website. Most stores will provide tracking for a small additional fee, and some members swear tracked packages ship faster, and this would also give information on where the light currently is (however some countries don’t update tracking info very often or at all). Paying by paypal gives you the most protection from losing money, and most flashlight websites accept it. Essentially if you don’t receive your item within 45 days you can make claim with paypal and they will investigate. The 45 day limit is pretty much set in stone, so be sure to initiate your claim before it elapses and don’t accept excuses from stores why you shouldn’t put in the claim (there can be elaborate or convincing false claims made by the store by saying they will make everything right or send a new light or give a refund if you close your claim, once you do your left high and dry with no recourse, paypal does not impose any conditions that impede resolutions as a requirement despite lies to the contrary you might be told).

Heatsinking

Heatsinking is an extremely important part of any LED flashlight, unlike halogen and incandescent bulbs LEDs are heat phobic, and prefer to be operated as cool as possible, being cooled to room temperature will produce the best performance (even lower LED temperatures would work even better but is almost impossible to accomplish). A good heatsink can make or break a flashlight. While LEDs are extremely efficient (compared to incandescent bulbs), they still generate a high percentage of their power input as heat, anywhere from 50-90% of the energy that goes into the LED is lost as heat. The main difference between LEDs and other bulbs is that heat is not radiated outward from the "filament", it exits the LED through a heatsinking pad on the underside of the LED chip. If the heat is not removed efficiently from the LED die it will lose efficiency as it heats up and if the heatsinking is extremely poor and the led is overheated repeatedly or for a long period of time it will eventually fail.

The ultimate goal of a heatsink is to move as much heat away from the LED as quickly as is possible. Due to this copper is ideal (but is very expensive) due to its thermal transfer properties, it can absorb huge amounts of heat, and it can spread that heat out throughout the entire heatsink more quickly than other metals. In addition most mcpcbs have a dielectric layer between the LED and the mcpcb body which slows the rate of heat transfer. It is for this reason that in high power lights Sinkpads (or similar) are preferred. They have the dielectric layer removed for optimal heat transfer from LED to mcpcb which is required for sufficient heat transfer above rated current levels and also improves lumen output at rated levels since the led runs cooler. Be wary of copper mcpcbs, many are sold that still have the dielectric layer present which gives very little improvement in transfer rate over aluminum mcpcbs with dielectric layer. Sinkpad and Noctigon are the most well known direct connection mcpcbs, and there are a few others available, but one should always assume an LED is mounted on a conventional mcpcb unless it is stated or proven otherwise (again beware of chinese fakes which claim direct thermal path)

Another important consideration for heatsinking is the contact area in between various materials, or the thermal path, an example would be in between the LED star (mcpcb) and pill. If they are just placed near each other there is very little contact, and thus the overall heatsinking is poor, however if the LED star is lapped (polished to a shine) as is the heatsink and they are then joined together (and both are flat or have good contact) then there is an excellent thermal connection. Arguably it can be further improved if it is soldered, this means either soldering the LED star directly to the heatsink or soldering a Sinkpad directly to the heatsink. Solder has a lower thermal transfer rate then aluminum or copper but testing has shown little reduction in the heat transfer rate. Thermal compound is also used to aid heat transfer. Its purpose is to fill microscopic gaps in between pieces of metal, it has extremely poor thermal conductivity compared to metal but a better transfer rate then air. Therefore it should be used in very small almost invisible amounts (scraped onto both surfaces before they are joined) but many lights have a blob of it between the star and the pill which will reduce the rate of heat transfer rather then aid it. Also common is for a drop of it to be on a visible corner of the star so it appears to be used liberally (which ironically is doing you a favour over a blob being present between mcpcb and pill).

One also has to keep in mind how the heat is going to escape the flashlight body, if the heat does not escape the flashlight body then the flashlight will keep getting hotter and hotter until the LED eventually burns itself out. It is for this reason that cooling fins are often cut into flashlight bodies, they give the light a greater surface area to transfer heat to air by conduction. It is also a good idea to have an anodized exterior because anodized aluminum has a much higher emmisivity (~0.9) than un-anodized aluminum (anywhere from 0.1 to 0.7). Emissivity is the ability of a material to shed heat by transmitting it as infrared radiation.

Vocab/Basic Concepts

GITD stands for Glow in the Dark. This is commonly available for o-rings and the rubber on/off switch cover

These batteries are not rechargeable and are rarely used in high power flashlights

These batteries are rechargeable

LED stars are the thin pieces of metal that LEDs are attached to

the process by which LEDs are attached to those stars is called reflowing

the best LED stars are copper sinkpads, this is because they are made of copper (great at heat dissipation), are fairly thick (helps to spread the heat through the whole star), and have no dielectric layer (this means there is nothing in between the LED and the bottom of the star)

due to all of these the sinkpads allow LEDs to be driven with much more current than if the LEDs were mounted on a normal star, and this gives a higher lumen output

the dielectric layer has a thermal conductivity of approximately .4W/(m*k) while copper is approximately 401W/(m*k)

MCPCB

metal PCB - Wikipedia article

PCB

a board that things can be attached to, in this case LEDs

Pill refers to the place where LED star is attached to a piece of metal to pull heat away from the LED.

Pills are often made of Brass or Aluminum, but the best pills are made of copper

Hollow Pill

hollow pills are pills where the LED star is not resting directly on metal due to the pill being hollow

P60s are a standardized type of drop-in, they go in P60 hosts. They were originally made popular by Surefire when Incandescents were the superior light source, but have maintained their popularity

Surefire and Solarforce both make very nice P60 hosts

Due to not using a screw in pill there are heatsink issues as there is no good thermal path for heat to escape the LED

People often try to fix this by wrapping the P60 in metal as seen here

a C8 is a standardized type of flashlight (usually) with a interchangeable pill

the pill screws into the host so heat is effectively removed from the LED

They have a standardized reflector size: 42mm diameter, 32mm depth

they are often preferred due to their combination of throw and flood

the C12 is a variant of the C8 with a deeper reflector and more cooling fins

this refers to applying something to the reflector to give it a texture similar to that of an orange peel (OP)

this increases the floodiness of the light at the expense of throw

smooth reflectors have a very smooth shiny surface for maximum throw

Datasheets are PDFs released by companies that list the specifications of their products

in the case of Cree datasheets they list the size of the LED, lumen output, vf, bins, and many more things

throwers are lights that can light up something very far away

they have very wide reflectors, which are generally deep, so as to allow them to reflect all of the light out the front

Flooders generally have very small short reflectors

Zoomies are lights with an aspherical lens in front of the LED, the lens can be moved forwards or backwards changing the beam profile of the light

the point of measuring tailcap current is to get a rough idea of how much current is getting to the LED

Calculating current to the LED

If there is one li-ion cell and one led

in single cell lights the tailcap current is approximately equal to the amount of current going to the LED

in two cell lights the tailcap current is about half of what is going to the LED

in three cells lights the tailcap current is about ⅓ of what is going to the LED

Otherwise you should calculate the wattage (voltage of all the batteries*amp draw)

then you divide that by the voltage of the LED and you have an approximation of how much current is going to the LED

More information here.

ANSI Lumens

ANSI standarizes a way of measuring lumens, it requires that you measure light 30 seconds after turn on

The Lens allows light toe xit the light while protecting the LED and ensuring waterproofness of the flashlight

the lens can also be designed to focus the light, like in a zoomie

they are made from either plastic or glass

plastic generally is more durable but allows less light through

some only let 80% of light through

glass tends to be more efficient, but can more easily shatter

it becomes even more efficient if it is coated in an anti-reflective coating that reduces refraction

coated glass lets as much as 98% of light through

AR glass stands for Anti-Reflective glass

foy bezels are bezels for solarforces that are filed down and polished to a silver shine

they were made popular by Foy of BLF

HA3 Anodizing is a much stronger type of anodizing compared to HAII, it is much more scratch resistant

TIR lenses are optics that are often used in smaller lights to replace reflectors

They are typically made of plastic and are generally conical in shape

For any and all information on different LEDs see these threads

There are two main types of threads, square threads, and standard threads

The first and most common are standard threads, they have a triangular shape and are often used as they are easy to mill

they are unpopular due to the aluminum grinding on itself if they are poorly made

this can be solved with lubricants such as Nyogel 760G

The nicer and less common type are square threads, they have a square shape and are extremely smooth

- Thermal analysis is a virtual computerized method of determining whether the light is capable of handling the heat generated by the LED, it is generally done with Solidworks

Special thanks to Scaru for all the infomation he researched and wrote for this guide and to everyone who has provided suggestions, updates and corrections