Spark SF5 XM-L2 NW

Handsome AA light!

The Spark SF5 uses a NW XM-L2 emitter that is mainly focused on using AA batteries.. There is not much improvement in output when using 14500 li-ion batteries! Please read on.

The main selling point would be the +/-200 lumen output on AA battery,

and its unique Carbon fiber sleeve

plus

the double reflector kit!!!!

And last but not least... it`s unique color

| Brand/model | Spark SF5 NW |

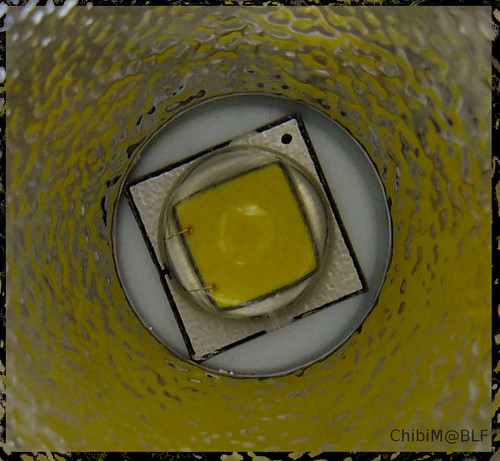

| LED | CREE XM-L2 NW |

| Working Voltage | 0.9-4.2V |

| Battery | AA/14500 |

| Switch | Side switch |

| Modes | 4+1: L, ML, M, H + Turbo |

| SOS/Strobe | No |

| Mode changing | Side switch: PRESS and HOLD |

| Anodizing | HAIII |

| Tail stand | Yes.... |

| Lock out | Yes... manually |

| Momentary-On | No |

| Coated glass lens | No, (but using a Schott ultra clear lens |

| Reflector | OP and Mule |

| Waterproof | IPX 8 |

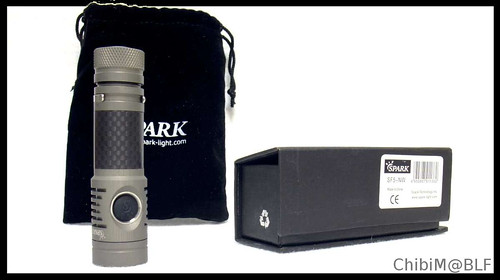

What you get:

Not much, but still a few noteworthy things.

- Spark SF5 Flashlight

- Small black storage box

- Black pouch

- Pocket clip

- flood / throw reflector set

- Very short little manual

The first thing that I noticed was the black little box.. which fits much better with this size of light than the regular stuff we get. And the pouch.....hmmm how can I use that one?

At the same time I was disappointed to see so few accessories. No holster, no O-rings, no lanyard...

The SF5 doesnt even have a lanyard.. in case you were wondering. But there is always the possibility to attach one to the clip..

That are a few points of consideration for Spark!

DIMENSIONS and WEIGHT:

"Throw reflector"

Length: 90mm

"Flood reflector"

Length: 85mm

Body diameter is 21.5mm

Head diameter is 24mm

Weight:

Without battery: 52grams

With AA battery: 78 grams

In comparison with other AA lights:

| Spark SF5 | Olight S15 | Eagletec D25A | Sunwayman V11R | Fenix LD12 | |

| length | 85mm | 87mm | 87mm | 100mm | 105mm |

| Dia | 21.5mm | 19.5mm | 18mm | 23mm | 21.5 |

| Dia head | 24mm | 23mm | 18mm | 23mm | 21.5 |

Weight grams |

52 | 46 | 24 | 60 | 54 |

left to right: UltrafireM5, eneloop AA, 18650battery, Spark SF5, Sunwayman V11R, Fenix LD12

Some side by side comparison: Mouse over with "throw reflector" mouse out with "Flood reflector".

HANDLING:

The SF5 is fairly shorter than the Sunwayman V11R and Fenix LD12. I wouldn`t say too short, but definitely on the shorter end of the spectrum.

Finding the switch in full darkness will be no difficulty. The switch sits in a a cut out in the head. This give a little more protection for accidentally switching on.

The Pocket clip is strong! it feels thicker than the one from the V11R, but the V11R clip is less flexible.. Much stiffer than the clip of the Spark SF5.

The NW emitter they use is probably a 3C.. not as nice as the 4C.. and more towards green if you compare the 4C and this SF5 NW side by side.

Because of the clip and bigger size head (with the heat grooves) it`s not as slippery as it may look like.

1 thing that I don`t like so much that it only has a side switch... I really like the V11R which has a tailcap for On/Off.

I know some people like side switch lights, but i really prefer something with a mechanical ON\OFF.

That was actually the main reason I sold my Olight S15.

The next thing that is seen many times with side switches is that you have to HOLD the switch while cycling through the modes.. I dont like that... but fortunately this one switches fairly quickly between modes.. faster than the Sunwayman C10R and C15A.

If it has a side switch, at least I would like to switch modes by CLICKING and not holding the switch.

UI and MODES:

- 4 modes plus Turbo.

- Low

- Medium Low

- Medium

- High

- TURBO

When Off, press and release the switch.. it will come on in Low

Press and Hold to cycle through the 4 main modes...

Double Click in any mode will bring you to TURBO.

Another double click and it will bring you back to the previous mode.

Turn OFF by short click.

1 thing to note:

If you are in Medium for a few seconds, and you want to go to high.. the light will start back from Low instead of continuing to cycle to high...

This is something I don`t really like personally.

At the other side, you will be able to go back to Low any time. when the light is off.. just by holding the switch for a second or so.

PERFORMANCE:

Amperage with AA battery:

- 1: 0.01A

- 2: 0.04A

- 3: 0.20A

- 4: 1.50A

- 5: 2.30A

Amperage with 14500 battery:

- 1: 0.005A

- 2: 0.02A

- 3: 0.10A

- 4: 0.30A

- 5: 0.70A

Manufacturer specifications: Run-time

Turbo: 260 lumens 0.9hours

High: 100 lumens 2.8hours

Medium: 30lumens 9hours

Medium Low: 32hours

Low: 10 days

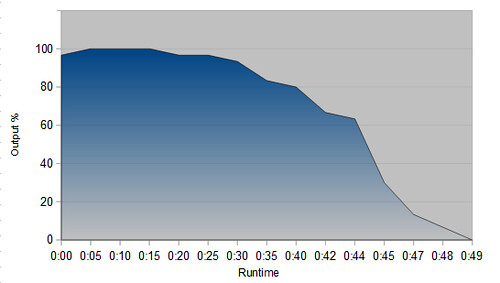

My test:

Turbo: 0.8hours

Medium: 8hours

I haven`t tested High, Medium Low and Low.

Note: I noticed after the following run-time test in Turbo, that it had some contact issues, and therefore sometimes not working in Turbo, only in High...

I worked this out, when I compared the output to the Sunwayman V11R, using my Lux meter.

So this is what I got from a normal eneloop AA 1900mAh min. before I discovered the contact issue.

Tightening the bezel solved the problem though.

Using a 14500 battery doesn`t help in overal output..

The Sunwayman on the contrary has a big improvement..

A positive side would be that the Spark SF5 would have a longer runtime in Turbo.

The V11R gives out about 200% using a 14500 over a normal AA battery

The Spark SF5 only produces about 10% more output..

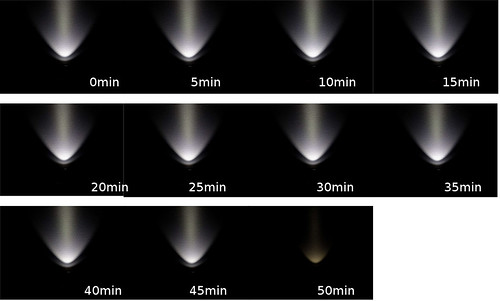

Pictures taken with Fujifilm Finepix F200EXR M-mode: (iso100 f3.3 1/25sec 6mm)

Note that I collected the output the last few minutes in 2-minutes interval, while the main part is taken in 5-mintues interval.

Even after it reached 0 on my Lux meter,it was still producing light, a few lumens... But at which I just stopped the run-time test.

PWM:

No...not in any mode.

camera set to 1sec.....

Low mode:

Very smooth.

Flood vs Throw reflector kit:

Here the comparison between the "throw reflector" and the "flood reflector".

here the reflectors:

here the comparison in beam pattern.

Mouse Out is "flood reflector" and Mouse Over is "throw reflector".

The flashlight is about 25-30cm off the wall.

The Flood reflector is great for using as a headlight for close up work!

Throw

Flood

Without reflector

In comparison to the Sunwayman V11R

Wallshots:

mouse Out : Spark SF5, mouse Over: Sunwayman V11R

The Spark SF5 is Neutral white, while the Sunwayman V11R is cool white.

Here some beamshot comparisons with the Sunwayman V11R (rated 216lumens) on AA.

Control shot:

Mouse Out is Spark SF5 neutral white... Mouse Over is Sunwayman V11R cool white.

Spark SF5 is specified as 260lumens on AA

Sunwayman V11R rated at 219lumens on AA.

If the V11R is 219 lumens, I assume the Spark SF5 to be around the 200lumens of an AA battery.

not bad! But not the claimed 260lumens, or the Sunwayman V11r is underrated..

or my eyes are just a bad judge?! NW versus CW?

Another comparison between the specified 1lumen V11R and the 1 lumen SF5 in Lowest mode:

Left: Spark SF5, Right: Sunwayman V11R

Left: Spark SF5, Right: Sunwayman V11R

There must be a mistake, or the V11R is not 1 lumen or the Spark SF5 isn`t..

My guess would be the Sunwayman V11R is not 1 lumen, but utie a bit less!!

A few more pictures:

No square threads, but lubed.

Summary:

PROS:

- Available in CW and NW

- 200+ lumens of 1xAA battery

- Carbon fiber sleeve, unique

- Color!

- 5 modes.. Enough to choose from

- No PWM

- Hold it`s own against the SWM V11R CW

- 2 types of reflectors, Flood and Throw

- size

CONS:

- No electronic lock-out (although I don`t like electronic lock-outs anyway)

- Lack of extra accessories, like extra O-rings and holster.

- Contact issue, sometimes didnt work in Turbo... (until I fastened the bezel)

- Color mismatch between body and the 2 bezels... (which is not a big deal for me, really)

- Not cheap @$50+