Clash!

Enlan

That is beautiful Dale! What is it?

It’s a Spyderco Vallotton

That would be a Spyderco Vallotton Sub-Hilt folder, and very nice too!! EDIT-Beat me to it.

My EDC for today, the top one in this Trio, an Enlan EL-04MCT not out and about - just around the house.

My Wave-modded Enlan EL01 .

Spyderco Endura Serrated.

Lightweight, and never lets me down.

Although its too big & sometimes puts Non-knife people off with its size.

Sometimes I carry a Spyderco Dragonfly or Cricket when a smaller knife will do, and to be more discreet.

I EDC a big ole honkering blade that Cereal_killer gifted me…sharpest knife I have ever owned!

I need to put some remoil on it, as it has a tiny bit of surface rust on it being in my pocket all the time, it ain’t the most beautiful…but man it’s a big ol’ chunk of steel and razor freeking sharp (I have never seen the cutting edge of a knife polished to a mirror finish before, guess that is why it’s so daggum sharp ![]() )

)

edit: CK, can you post a pic of it please

Today (same as every single day, tho sometimes I add in my spyderco Gayle Bradley)

wow look how broken in the G10 is getting on my p’kal, can you believe showing its age that much it still has its factory bevel on it shaving sharp (never even stropped!), I only use it for the occasional string, other than that I keep it in my back left pocket just waiting for me to actually need it for what its designed for (cutting people)*

*which I will be more than fine never ever getting to use it.

A camel bone handled Pakistani two blade.

I have two of this style. At first it seemed ridiculous for the second blade to be razor shaped, when it was so dull and the steel is soft. When I got it sharpened, I found the shape really does help keep a fine edge on it and that the soft steel is not a problem if I don’t mind sharpening it more often than a knife from a more advanced country. I love the handle, even though it had cracks that I patched with super glue.

I enlarged the choil cut of the clip blade with files, to preserve the edges of my stones.

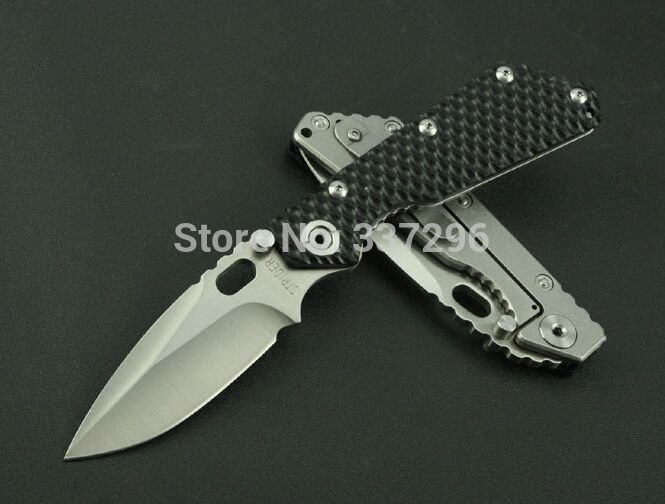

I just got this one, of course it is a cheap clone but it’s unique and new to me

I just got this one, of course it is a cheap clone but it’s unique and new to me

PLEASE:let me know if photo came up

I don’t see a picture.

Cold Steel Voyager Vaquero XL serrated and Cold Steel Mini Tuff Lite.

WarHawk asked me to post these:

This is an ontario Utilitac2

I converted it from a full spacer to stand off’s, acid etched the blade, polished the liners, wave modded it, converted it to take a benchmade deep carry clip (don’t remember what all that took, I think all I had to do was use new screws but I may have had to drill/tap it). I also polished the mating surfaces and swapped out the stock washers for PB (the heavy blade along with the polish job and new washers makes this the smoothest budget knife I’d ever handled). I also gave one to my cousin for his bday last year who had EDC’s a benchmade 9100 for 5+ years and he said at first he was hesitant to replace his BM with a $23 knife but within a few weeks the auto Stryker was in his safe and he only carries the utac.

Personally I hate tanto’s so I also sharpened it following an arc instead of at the 2 converging angles @ 20DPS.

They’re designed by Joe Pardue, the same dude that does designs for BM (and other companies). There are like 6-8 different factory config’s, things like coffin vs round handles and blade shape/color choices. Don’t have a link but you can pick them up for $23 shipped from US sellers.

Wow, it hates you lol.

When you post the link from photobucket make sure your hitting the “share links” button (little gear in upper right of thumbnail or big square on the right if viewing actual pic) and click on “direct link” to copy the link, don’t just copy the actual address from your browser.

Yup…that’s the Stabby Mcstaberton! (even like the rip stop camo too :D)

Thanks CK ![]()

Not too big, but big enough when I flip it open to lock it, it makes a loud click

Vantage Force Pro