I’d like to announce the first public release of PackProbe.

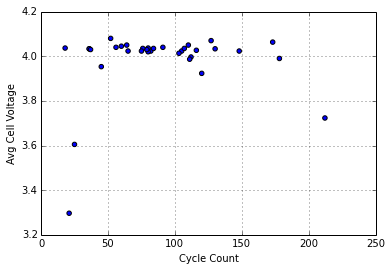

PackProbe is a tool for quickly gathering diagnostic information to use in assessing the health and age of most laptop battery packs. For example, here is data from one of the $12 Acer NOS pulls that people have had such good luck with:

PackProbe is for budget-minded flashaholics, and anyone else, interested in recovering inexpensive, high quality, rechargeable lithium ion cells from used and surplus laptop battery packs.

PackProbe gives you a quick (1 minute/pack), inexpensive ($20 in parts) way to get at the data stored in almost all laptop battery packs. That data includes manufacture date, count of charge/discharge cycles, pack voltage, and, in some cases, voltages for the individual cells.

The typical approach people use for assessing the quality of laptop pulls is to tear the pack apart, separate the cells and check voltages for each cell. Cells below a threshold (often 2.5 to 3v) are recycled. The rest are charged, and checked for excessive discharge overnight. Finally, the remaining cells are put through a cycle on an analyzing charger. This approach can lead to good cells being pitched, and requires the investment in time and effort in cells that end up failing.

The additional information offered by PackProbe can help you decide whether a pack is worth tearing apart in the first place, and whether low cell-voltages are likely due to excessive self-discharge due to old-age, or just spending time on a shelf.

To use PackProbe in its initial release, you’ll need an Arduino-compatible board, familiarity with running and modifying arduino sketches, and some basic electronic prototyping supplies. The documentation includes more details. I’ve also included information on pinouts for packs I’ve worked with, and advice on discovering pinouts for unknown packs.

The next version of PackProbe will be refactored to make it easier to run on a variety of Arduino boards without editing the source code, and after that, I plan to make it easy to input pack data into a web-based database to make it easier to track your cells, and to try and find patterns in pack “aging.”

I think this will probably be of interest to people beyond the BLF community, so I plan on setting up a forum for people to share tips and feedback. For now though, there are comment forms on the site, and this thread.

Another example, this one from one of the Lenovo packs that Hagg911 is selling (unfortunately, I haven’t figured out how to get cell real voltages from Lenovo packs yet):

I hope people find it useful. Feedback is appreciated, as is help debugging communications with HP TD06 packs (and similar), and figuring out how to get voltage for individual banks of cells from Lenovo and Dell pack.

Thanks!