I had a batch of 100 Nichia 119 boards made by Kerui in Shenzhen. The reasons were several:

-every now and then I wished I had a board for leds that only have two electrical pads with no thermal pad in between. I could not find them for sale in Europe easily. Interesting leds without thermal pad that will work on this board are the Nichia 119, Luxeon Z, Nichia 276A and other UV leds, the new Nichia 229A and 144A series, and all mid-power leds that are sometimes interesting to put into small flashlights (i.e. Yuji leds)

-I wanted to check out the Kerui board manufacturer (result: they were a pleasure to work with, lots of attention for the customer despite the small order)

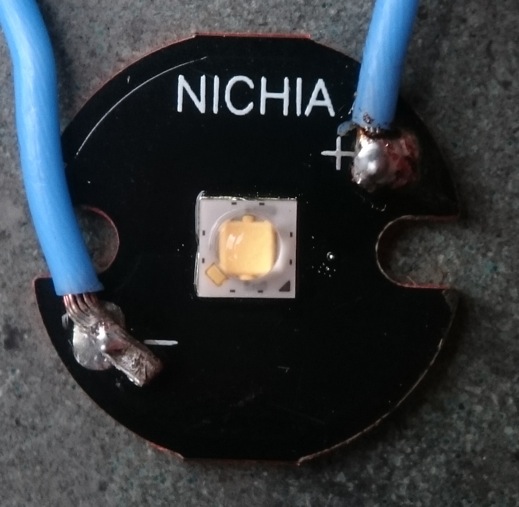

-I wanted to see how such a board performs: trying a design with maximum heat dissipation despite not having a DTP to the core, and test if they are any better than existing similar boards. So the electrical pads widen in a large pour, and had the core made of copper (not knowing if that makes that much of a difference, at least it looks cool, and you can solder it). To make them as versatile as possible for use in flashlights, the diameter is 16mm, and the thickness 1mm.

So now I'm stuck with 128 of these boards that costed me $2 each (all-in).

So here's a test of the board.

The idea of the test is to take one led (the only led available to me was the grossly outdated 92CRI 3000K Nichia 119A) and reflow it repeatedly on my board and a generic board, and do full current-to-output/voltage tests to see how they perform.

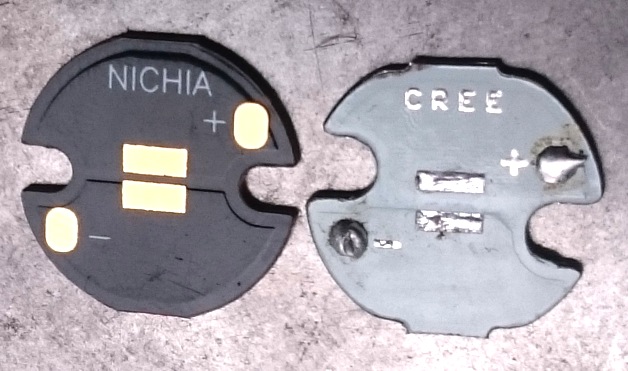

The only board I had to compare my board with was the Nichia119 board that came with the Convoy S2+ UV Nichia 276A. It looks very similar, with also the electrical pads widening into a pour, but under the led is a wider gap and the core is aluminium.

Note that it is labeled 'Cree' while I'm not aware that there are Cree's with this footprint ![]()

I did 5 test-runs with the Nichia119 led:

*I first reflowed it on the djozzN119 board and did 2 test-runs up to 2A, to see if there were any 'burn-in' effects (there were not)

*then I reflowed it on the genericN119 board and did a test run

*then back on the djozzN119 board to see if the performance had not changed, test run (performance was still the same)

*and last again on the genericN119 board and did a test run, to see if the (differing) results were consistent (they were).

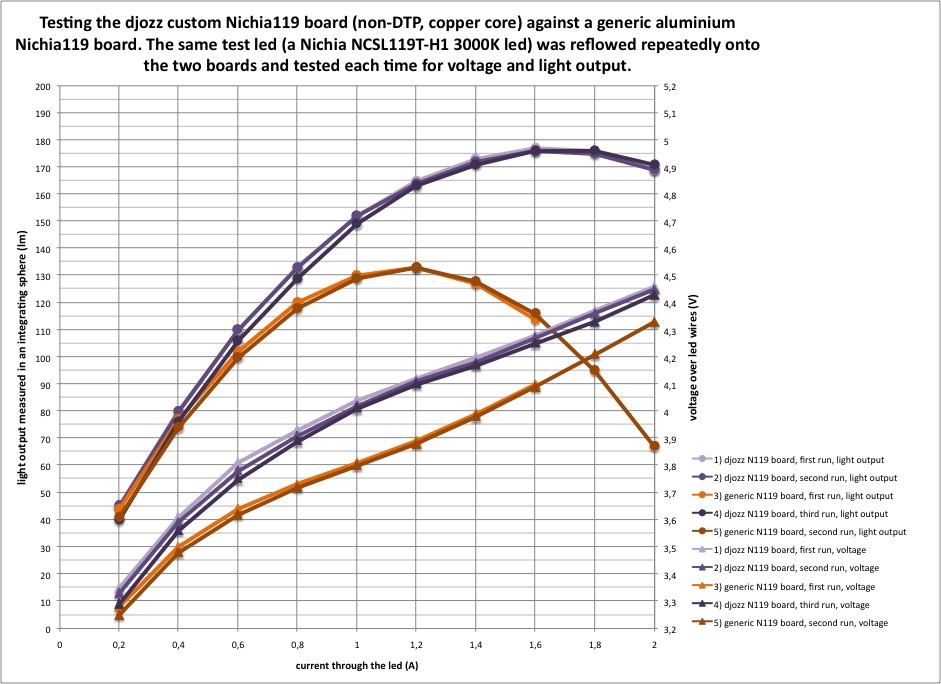

Here are the results in a graph. I made the djozzN119 results in shades of purple, the genericN119 results in shades of orange/brown

I had not expected a difference that was so obvious: my board does clearly better, at 2A the led was still close to maximum output, while on the other board the output was already halved. Note also that on the generic board the led runs at a clearly higher edit: lower voltage, up to 0.2V at 1A, this must be caused by the higher led-temperature.

So what is the reason for the new board to perform so much better? I can think of 3 reasons, what the contribution of each effect individually is I do not know:

*the wider gap (air!) under the led on the generic board lowers the heat dissipation area under the led, right where it counts most

*the dielectric layer on the Kerui made board is superior: less heat resistance. I have not dived into the heat conductivity numbers of various manufacturers (I should :-( ), but I'm sure it varies.

*the copper core stays cooler than an aluminium one and thus also the heat passes the dielectric layer faster.

A remaining question is: how much worse is this type of board compared to a DTP-board? I can't test that for this board because the DTP boards are for a different type of leds, but my guess is that over 3 or so amps the DTP board performs better. In my 6x XM-board test a non-DTP copper board even up to 5A was almost just as good as the DTP ones.

Conclusion

I succeeded in what I wanted: I now have a bunch of boards for non-thermal pad leds, and they perform better than at least the one generic board that I had around.

_____________________________________________________________

EDIT AUGUST 24, 2017: Sold out! I have just a few leftover that I would like to keep for own use.

Now for getting rid of the surplus boards. I really wanted to order these boards, for occasional use, and because I was curious about the performance. But even though the minimum amount that could be ordered of 100 pieces is extremely low for a direct manufacturer order, I do not need all 128. And I think that the $250 that I lost on it a bit much for the (though fun!) ordering experience and the bit of knowledge that I have gained about the thermal performance of led boards.

So 110 of these boards are for sale now, leaving me with ideally 18 pieces that should be way sufficient for whatever I want with them. Since it will be cost price, I do not bother posting this in the commercial sellers corner. The boards will be $2 a piece plus shipping. Shipping for up to 8 boards is $1.40 worldwide, 8-20 is $2.80, 20 to 40 is $4.20. A bubble mailer plus ziplock-bag (I will tape them in) is 0.30.

Example: 7 boards will be 14+1.40+0.30=$15.70

Please reply in this thread how many you would like, and PM me the address the boards must be sent to and I will PM my Paypal address. First come first go. I will probably collect demands for two weeks before I ship a bunch out, but it all depends on how many, if any, are sold.

I have no idea if these boards are interesting for anyone but me but I hope for the best. The price could of course be better if many more would have been ordered, but for this niche board I do not think that would have been wise.

Thanks for reading!