Hi BLF!

I need help and some “enlightenment” in this issue!

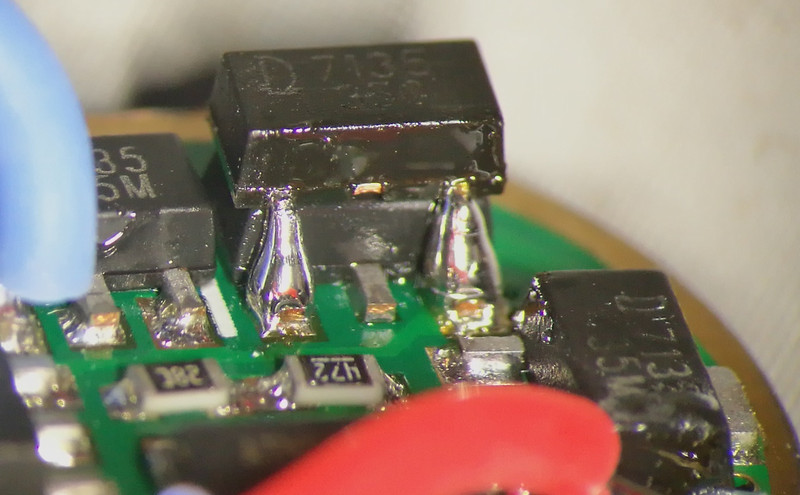

Hum, let’s say that have some damaged biscotti drivers that are plenty of 7135 chips, and that I would want to stack them in some drivers in use.

The targets are also biscotti drivers (7135*8) that I use in my Convoys S2+ and in 2 modded lights.

The LEDs used in those lights are XML2 U2-1A.

Besides the technical aspects of un/soldering that I need to exercise to retrieve them in good conditions, I need help on this:

1 – How many chips can a driver /LED like this hold to make it functional without burning?

2 – To install the chips, they need to be installed in the part “inside” the pill or in the part of the spring?

3 – Depending on the answer to the 1st question, stacking 4 chips would increase considerably the amount of lumens?

4 – The amount of heat produced due to stacking would be too much to hold the light in the hand for some minutes?

5 – Would I need to change the driver’s stock wires?

6 – Last but not least…would it be worthy to make all this, considering the possible amount of light gained in the process?

Thanks for your answers in advance!

I inform that I’m not aware of technical aspects like these, so I would appreciate explanatory answers to understand the stacking process as a whole, but also to be able to modify these specific drivers / LEDs I have!!

I also inform that I have no measuring tools to accompany this process, so this will be like a blind experience, guided by you people here ![]()

Best regards and thanks!