This is awesome!

This driver is also perfect for driving high power UV led from one Li-Ion as they have high Vf.

Good, but I'd prefer to see how the figures are under a worst-case scenario.

Can it handle its duty well when the input voltage is barely above cutoff? At 3.01V, let's say. :-)

For these high drain duties, it'd be also a nice idea to set the cutoff a bit lower than usual, maybe 2.9 - 2.8V.

Cheers ^:)

Great job Loneoceans! Very impressive! Welcome to BLF! BTW, I do have small springs if you need some. Let me know what size you are looking for. You can PM me and I could send them to you free if you’re in the USA. ![]()

Willie

Nice work, thanks for sharing. Sitting under a hot LED encased in a host with no air flow. I think drivers bleeding out that much heat might need potting. A few good materials out there should nip frying in the bud.

I bought a bunch of ATtiny84A MCUs :). Let me know if anyone is interested in a board with populated and programmed MCU (only MCU, you need to solder on the rest yourself) :). The rest of the details and BOM can be found here: www.loneoceans.com/labs/sales/gxb20v1

i am! :D

Yes please!

Very interested too! ![]()

Sounds good. I am in for one.

if you could make 17mm version, i’m IN

So... I made a whole bunch of improvements to the GXB20 V1..

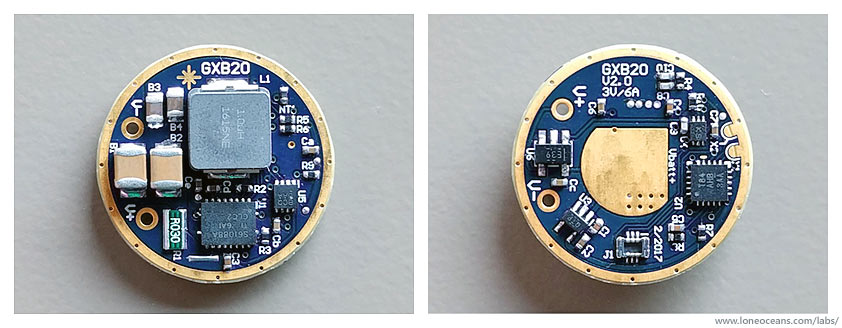

I just received the news PCBs for it... introducing the new GXB20 V2! ![]()

Still writing the (improved) firmware with a lot more additional and optional functionality, this time with 3 extra mode selection jumpers or E-switch control. And a complete layout redesign, on-board programming connection which will hopefully be a lot easier to use, and improved power electronics.

More to come soon! :)

V2 looks nice!

WOW very professionally built. Great looking with plenty of retaining ring clearance.

Different components used? Besides layout, any hardware changes that I can take when I eventually get around to building the previous versions I have?

Different components used? Besides layout, any hardware changes that I can take when I eventually get around to building the previous versions I have?

Hello, yes there were some slight changes in the feedback and digital potentiometer allowing for more variations in brightness. I also conducted some experiments in the power section but I don't think there are any hardware changes needed to be made so far (some changes I made resulted in same or slightly less efficient results so the original is good enough :) )

Another quick update and thanks again to everyone who's been following this project!

GXB20 Version 2

In short, the changes I've made for the V2 version turned out to be an improvement over the original by a small amount, and after a little more testing I think I'm happy with the result for now, and the GXB20 driver has achieved all the goals I had set out at the beginning of the project!

By no means is this a complete nor 'commercial' driver, which will certainly require a little more optimization and better firmware, but I think I'm quite happy with how it is as-is, for a hobby project. Currently I'm working on finishing a more complete write-up on this driver, and will be publishing everything open-source for all to use and to fabricate boards (e.g. from OSHpark).

Some notes on the additional improvements of the GXB20 V2:

- Better placement and layout (I hope!)

- Much more levels of constant current brightness (256, adjustable using 1 resistor)

- Improved lowest level of CC brightness (just around 1mA - true 'firefly' mode)

- Modes for my own firmware: 1 = firefly <1mA, 2 = low ~180mA, 3 = mid ~600mA, 4 = ~1.8A (~1000 lumens), 5 = 3A (turbo)

- Measured efficiency of 92% at 3A (~6.5V) output

- Two new solder-bridge mode jumpers + extra GPIO for easy mode selections

- (needs more firmware work to take advantage of all of these)

- New 0.4mm pitch micro programming header for ATtiny84A

- Works better at lower voltages when approaching 2.5V

- + maintains all the features of the original GXB20 V1

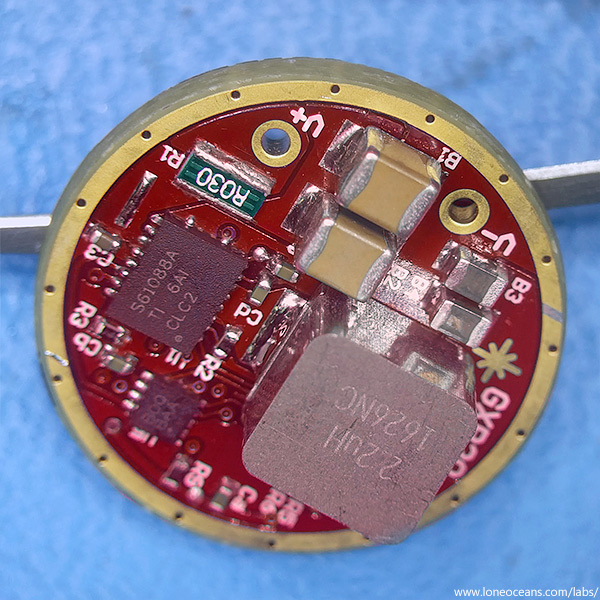

I did some experiments in the power section but it turns out that they didn't make too much of a difference (e.g. in the previous post you can see I used a bigger inductor but didn't see much benefit). The final improvement I'd probably want to do with this driver is to fabricate using half-thickness (0.8mm) PCB and 2oz copper, and of course continual work on the firmware to improve things further like adding more modes and improving EEPROM performance using a random hopping scheme.

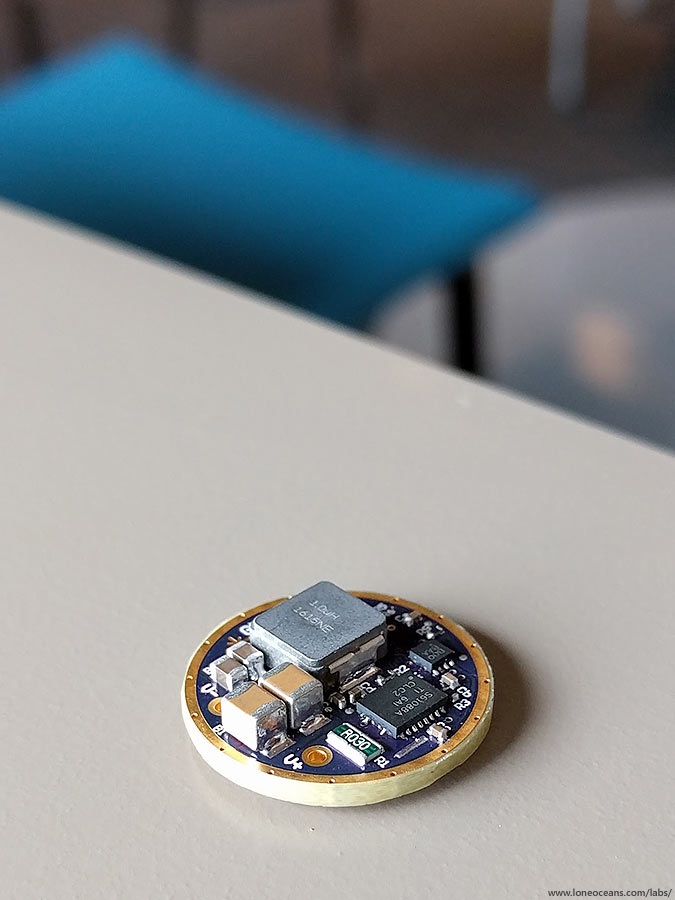

Finally, above is another view of the GXB20 V2 driver.

Looking good :+1:

Good news! This is a pretty cool result for a hobby project!

That looks so neat. :+1:

The side picture gives another perspective to the difference in height size of the components.

Were you able to hit the 95% efficiency goal? Remarkable work here.