![]() I’ve used calibrated texta marks for years.

I’ve used calibrated texta marks for years.

What did you calibrate it with ? :laughing: Eyes…? …and how did you calculate…with the universal whiskey units - fingers? :laughing: ![]()

Of course, I could accurately split a diameter into thirds because of the chuck jaws but anything else would be measuring marking and holding it in position with my hand :disguised_face:

One way you could put degrees on the spindle would be to print out a degree wheel, cut a hole in it the size of the spindle and away you go. ![]()

I used this. https://www.ebay.com/itm/Mr-Gasket-1570-Cam-Degree-Wheel-Universal-7-Inch-/263692855400

I already had it laying around from back in my hot rod days.

nice one pp,

you could try a dressmaking tape and a calculator

Yeh, I put an index wheel combined chuck stop back in post #78 on my previous lathe. I kinda liked how simple and easy that was.

Thanks for the link moderator007. I’m wondering if the smaller increments might be useful in the future….? If it were useful I think I might go with a wheel that has 360 instead of 2* 180

e.g.

This rudimentary device I cant take credit for but is very handy for trueing thin parts in the lathe

I think the thicker the shaft the better

simply clamp part gently in chuck and move the bearing in till it rotates continuously

stop the lathe and tighten chuck completely.

subscribed!

Thanks for the update ltp. I wondered what I was going to use it for. Can you make me a holder?

I got around to fitting the index wheel. I had a use for it so ‘had to get it done’.

I really needed to make a spindle lock as well but couldn’t come up with a suitable idea and I was impatient to get the job done so used this ingenious contraption.

The compound slide also needed some attention. The small bolts that lock down the compound angle were starting to strip the threads so I fitted some larger bolts. It took a bit of shaping of the bolt to get it into the t-slot. The pic below shows one old and one new bolt.

Here’s a pic of the project.

Nice finish up pp. Where do I put my order in for the degree wheel mod? ![]()

![]()

I’m jealous pinkpanda3310, your comp cam wheel has the full 360 degree increments. :cry:

Looks good and should be pretty useful. :+1:

Finally able to reply. Went to the eye doctor and have had blurry vision all afternoon :confounded:

Like you need one with your mad skillz ![]()

I have you to thank for the idea so… err… Thanks! :+1:

nice pp ,curious as to what the project is

It as for this crazy Titanium light pp built.

so I have been quiet for a bit,

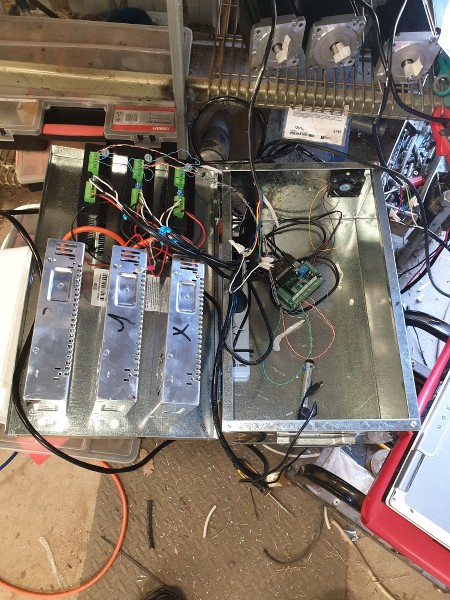

but decided to cnc the mill drill,still using the original screws

and very basic bracketry (work in progress)

power supply’s stepper drives ect

the old dell laptop from 2004 got a new lease of life with Linux cnc installed

updated the drive for the head with a belt reduction and fitted a gas strut to the other side

has improved “z” speed a bit (12”per minute)x and y are about 40”minute

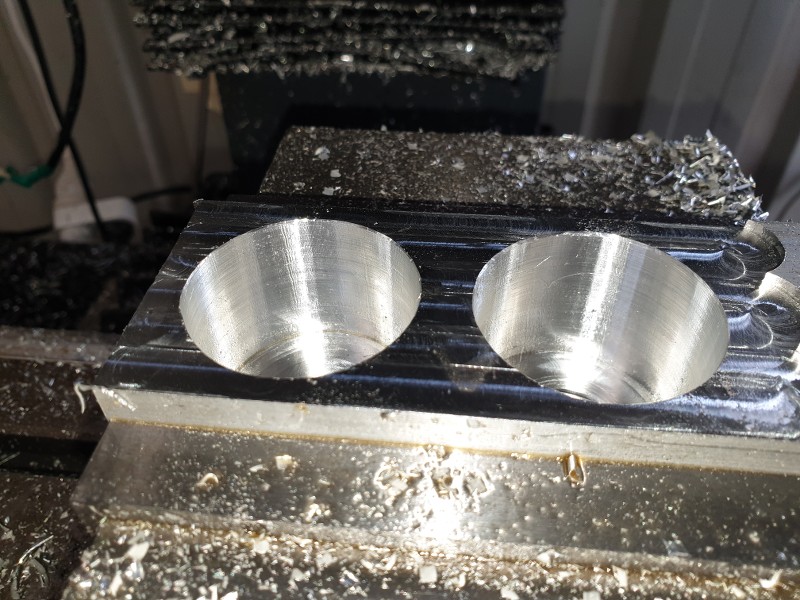

bored a couple of holes and did some facing using a10mm end mill.holes are .004”

elongated but accurate enough for most chores. Ball screws would improve it but would increase the cost

one thing it does do is make a mess (14 mm endmill boring plate for column mount)

been making a few signs for family ad friends more to learn the cad/cam/G-code. side of things,

It’s a bit of fun.

It doesn’t “look like you’ve been quiet”

Awesome project :+1: :+1:

I had the privileged of seeing lostheplots nc mill in action last weekend. He is one very smart cookie. To say the problems he had to work out would have put many others off but he stuck at it and made a terrific machine. Now what do we all want made. ![]()

Ah, had a great ride with him, lostheplot and my nephew as well. ![]()

What I do is to use a large square, (ground on all sides) tool bit and hold it tight between the work and the chuck face for a quick fit up. If you have a large enough space behind the work to slide it between the jaws. You may be surprised how true it runs for general work. Just be sure to pull it out before spinning up the chuck ![]()