You’re right Dale, I assume basic skills, but with a bit more skill and perseverence there are more options. Another one is converting the stock board to DTP like comfychair once showed and that I used for a F3X mod: Mod: LuckySun F3X

Thank you for the welcomes DB Custom and djozz! I already feel at home!

I like both ideas, modifying the PCB to include copper slugs and creating an aluminum shelf. Mine actually has 12x XML-T6 clones so I have about 25% more power I can pull with some good heat transfer. I’m wondering if my PCB is direct drive on high or not but I don’t have an oscilloscope to check.(I assume it is.). The copper slug mod on that F3X is super well done. It’d also be nice but nearly impossible to find a ready made drop in copper shelf, however it would be nice. I need to swap out my ir3034b and reroute the buttons controls.

As of right now with fully charged batteries I’m meausuring 8.35 amps at the tail cap pulling 3.5v through the emitter. so almost exactly 700ma per FXML-T6. maybe 25% more and then next Ill splurge on a BLF Q8 ![]()

Ill probably post in the previously mentioned thread from 2017 to get a discussion started. Ideas everywhere because of the coffee and late night. ![]()

You can buy an BLF Q8 driver from Sofirn, about $10 I think, that would be a nice upgrade to your light. ![]()

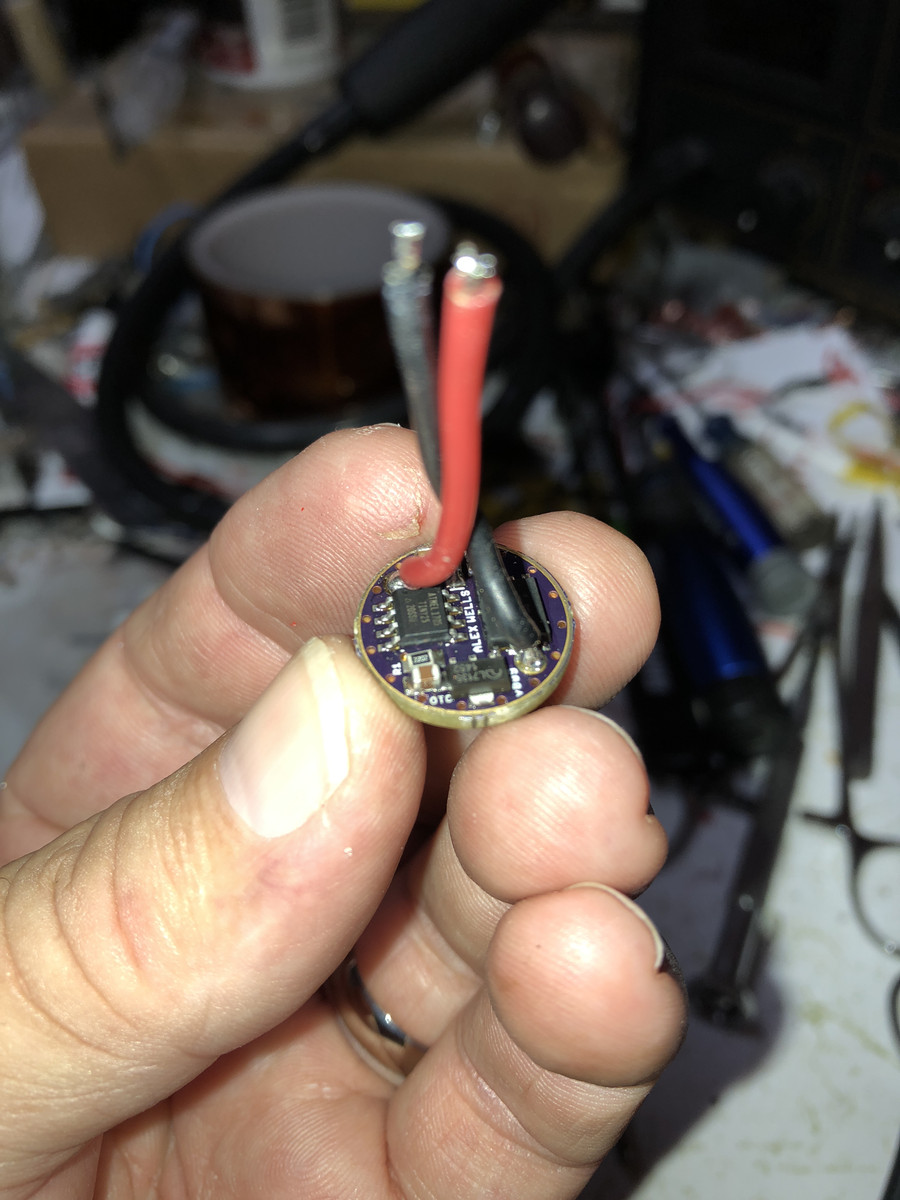

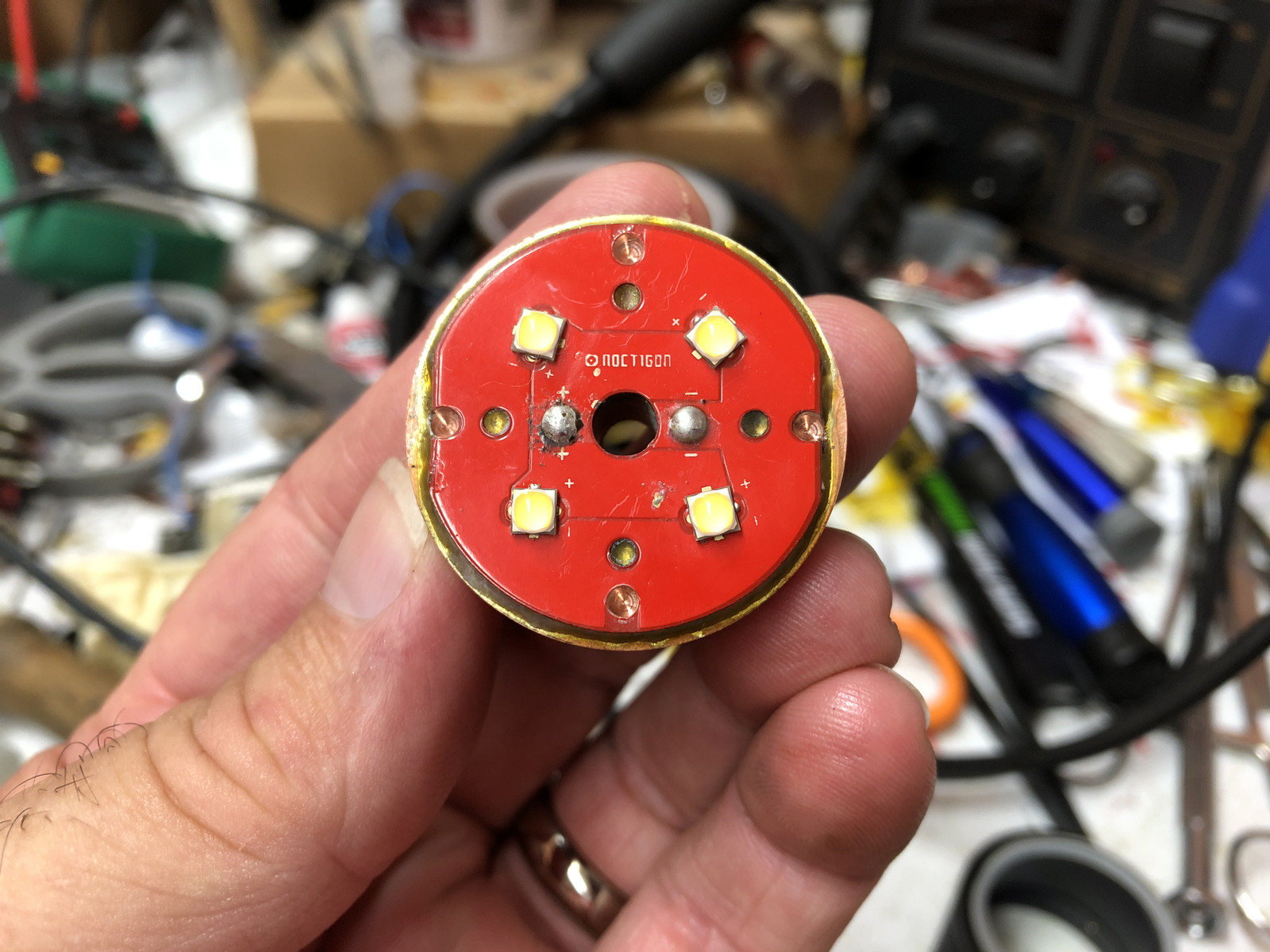

I hope I haven’t already posted this and forgot… when the Emisar D4S was coming out I liked the MCPCB and optic that Hank made up for it (the optic from Ledil of course) So I bought a couple of each from his site and build an Eagle Eye X6 host to be a variation of the D4s, this one uses Bistro with the high current fix. The emitters are Samsung LH351D in 80 CRI 5000K variant. The copper MCPCB is re-flowed to the custom heat sink which is in turn glued into the X6 head with Arctic Alumina Thermal Adhesive. I also used an AR coated glass lens over the optic to protect the softer material. If I remember correctly it’s making 5300 lumens on a top cell (Sony VTC5A)

Build pics of the Quad X6…

Ah, should also point out that the above X6 is one of two options against a modified Q8 in my 18,000 post giveaway. (the one that ends tomorrow at noon. less than 24 hours from now.) Just saying….

How expensive was that copper bit and how much does it weight?

I’d like to know.

The Te/Cu used was approx $9 worth of bar stock, weight should be around 1/2 pound. (1” of 35mm bar is .478 pounds)

Of course, I had to machine it to fit the X6 head as well.

(what with the reduction to fit into the head and another reduction to fit the emitter shelf, as well as the holes for wires, it should be around 6 ounces. I didn’t weigh it before installation and it’s now glued in)

I have zero experience machining (does a dremel and cut off wheel or sanding barel count? ;)) I do have a ton of micro solder and reflow experience however, these SMD components are about twice the normal size I’m used to working with. I’ve got access to a rotary tool and bits, a Weller solder station, and one of the chinese reflows. Copper while super effective, is further out of reach due to cost and it work hardening during machining in my experience. I wonder if anyone has tried to use heavy gauge copper wire or even heat pipes to improvise an odd shaped shelf? Hmmmm…… :sunglasses:

You don’t really need to.

Just get a 0,5-1mm copper sheet, cut a bit into the desired shape and size, and put it below the MCPCB for additional thermal mass.

Heck, you could even stack them using solder paste and a heatgun,

Or just get this monster of a light with a 10mm copper shelf and mod it to your liking:

Now that’s thinking outside the box !! ![]() :+1:

:+1:

Sounds like a good idea BlueSword I could also bond the copper plates with eachother using thermal grizzly liquid metal and then past between the top plate of the shelf and the emitter. Drill and tap a couple locking screws too maybe? Idk, ill have to do some more reading.

It could work yes. Solder would be better obviously, but liquid metal would work well until you get a hot air station like I recently did.

Dollar to a box of donuts it’s a brass pill in that light, not copper. ![]()

It has been reviewed, and verified that is a 10mm copper pill.

Besides, technically, since copper’s thermal mass is about the same as brass, it wouldn’t really matter in terms of heat capacity potential if it really was brass instead of the verified 10mm copper.

Although the heat dissipation would be slower, quite a bit slower in fact.

The thermal conductivity of brass is less than half of copper. It might hold similar amounts of heat once saturated, it’ll just transfer the heat slower.

Also, does lead transfer heat better than indium Gallium?

Also Based on looking at numbers the graphite beats lead by 5 w/mk. Also Aluminum beats Brass, and is easier to machine/dremel. Copper wins total at around 385 w/mk, but liquid metal is almost 50 more than that of leaded solder. At 73 w/mk, vs 50 w/mk. This is all from googling out of curiosity.

It’s not only thermal conductivity which matters.

Liquid metal is better yes, but being electrically conductive, if it flows out, there is a high chance of shorting out a component. It can’t also be used to stack copper layers for obvious reasons, so can’t use it to fuse multiple copper layers if you aren’t a machinist.

Another thing is that you do not want to mix liquid metal and aluminium, at all. You have been warned.

Liquid metal is also very expensive. It’s also hard to apply. Finally, thermal performance(not thermal conductivity) is usually better with solder, unless you apply a very thin layer of liquid metal.

You can simply remove any excess liquid metal after screwing down whatever pieces you’re using.

Nothing else will flow out.

As long as something is holding the copper layers together, like the screw holes in regular MCPCBs, of course you can use liquid metal.

It’s not hard to apply at all, just rub it around with a Q tip.

Liquid metal is literally just that, a liquid, there is no “you need to apply a thin layer” because any excess will simply be squeezed out when you tighten the MCPCB down or whatever it is.

It will always be the minimum thickness necessary.

Unlike soldering, which can cool too quickly (especially when soldering large pieces of copper) causing excessive layer thickness, cold welds, and other problems.

Liquid metal is basically solder that doesn’t harden when cool, that’s why it is so good.

Maybe I’m a bit biased because I, well, ummmm… did something bad to a friend’s PC a while back. :person_facepalming:

Yeah. Liquid metal is the best in this case. I’d still go with a hot air reflow+preheating+solder paste for the best results, for me of course.