I had this idea to make my own "pocket" 26650 host since there were not many options out there aside from cutting down a Mag2C (which I have already done). No lathe was used here folks - all machining was done with a hacksaw, dremel, files, sandpaper, and plenty of patience.

Here is what I came up with:

- 26650 "grooved" host - Mag2c body cut-down with front and rear threaded tailcaps

- xm-l emitter

- 2.8 amp 3 mode driver (shiningbeam)

- custom aluminum pill

- aluminum reflector (pulled from another light)

- glass lens

- tailclicky

Special thanks to Ma_sha1 @ CPF for his "no lathe" Mag-modding cut-em down ideas here.

Size comparison (Left to right)

Mag2c stock, Mag1c, 26650 custom host, Solarforce L2, 26650 battery

Glow ring in front

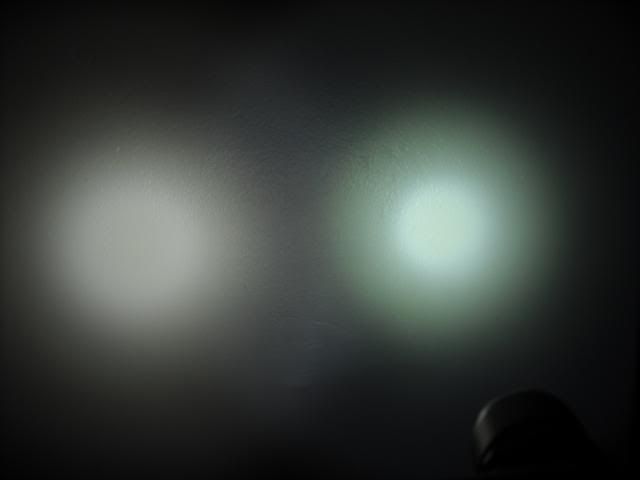

Left - this host with 5000K xm-l

Right - solarforce with 6500K xm-l

Size in hand

-------------------------------------------------------------------------------------------------------------------

Edit 12/13/11

I've been asked to provide more details to this build, so here they are.

Here is an exploded view of all the components

Heatsink was made from round aluminum stock (2 sizes) cut, filed and glued together with JB weld (for strength) and arctic adhesive (for heat transfer). It was then wrapped in copper foil to form a tight fit into the body.

The 5000K XM-L (Digikey) was reflowed onto a 16mm board (from KD) and mounted with HS paste

The bottom of the HS was ground with a dremel to recess the 2.8A driver (Shiningbeam or KD, can't remember which). The black electrical tape is to prevent shorting of the negative contact against the battery (+) terminal.

Negative contact is made by connecting the driver outer ring with the side of the HS, which is then pressed fit into the body. The inside of the body was bored to accommodate the larger 26mm battery, which also removes the inner anno layer.

View down the bored body. You can see the seam on the inside where I joined the two threaded halves of the mag body to permit using stock tailcaps on either end - one for the emitter/reflector and the other for the tail switch.

Light engine sliding down into body. The fit was made tight using copper foil. The idea was to have the fit snug enough for efficient heat transfer and good (-) contact, but not so tight it could not be removed if necessary.

Bored out tailcap (both were done the same way) using a drill bit first, then a dremel grinding tool to gradually widen it to the desired diameter.

Components of the head - GITD O-ring, glass lens, aluminum reflector, washer for proper focus and prevent shorting of the reflector onto the emitter contacts.

Tailcap and switch. Details of this build can be found on my build at CPF here.

Finally, beamshots. These were taken with a point and shoot camera, so I could not manually adjust settings, but this will give an idea of the output. Distance from my 2nd floor balcony to the dumpster was ~100 feet give or take. All lights were running full power.

Control

This build @ 2.8A. Beam is quite floody with some throw. Tint is very nice

Ultrafire 502B with XPE R2 dropin @ 2.6A. Much narrow in comparison

SkyRay 1JC8 modded with XM-L @ 2.8A. This was a little fuzzy.

Finally, a Mag2C modded with a quad XP-G R5 running @ 1.4A per emitter.

.

.