But can it run Crysis?

Absolutely incredible work as usual. I don’t think there’s anything else like the MELD UI.

id buy that

thats super cool!

Wow! this is amazing. Would love to see more manufacturers doing this especially on bigger lights like the MF01S.

Wow. Just wow…

I’ve been contemplating adding one of those small OLEDs to a flashlight a while, just received some in a week ago. But I see you’ve beaten me to the punch… by 3+ years ![]()

I also just received some of those TTP223’s in two days ago and have been playing with them. Incredible little chips, I’m surprised that I just now found out about them. Amazingly low quiescent current, very responsive, and flexible (momentary/latching, high/low option, etc). These will certainly be making their way into some of my flashlights. Had I known about them earlier, one would be in this year’s OL competition.

I also continue to be impressed by your ability with the enameled/magnet wire. Might impressive using that teensy-tiny stuff and keeping it all straight.

Well done! Well done!!!!!

Spectacular! ![]()

anychance youcould do a break down on how much this would cost

Not much. Off the top of my head:

Display $3

Microcontroller $1

Power monitor $1

Touch sensor $0.1

7135s $1

Various passives, wire, materials $4

RGB emitters $6

UV emitter $10

Breakout board $0.3

So in total the added components probably cost less than the host light

Stunning Work! We do need to get there - features many lights could/should have.

Didn't even realize you did a similar to mod to a SD Mini 3 1/2 years ago! The SD Mini is still one of my favorite lights all time.

Very impressive!

i have to bump this again to ask ,how much would one of these cost to make

and how much wont one cost to buy retail

thanks man, im super impressed

I answered above. Total added parts about doubled matched the cost of the original EC01 ($30)

Its not the parts costs its all the work and know how to make one

Also usual flashlights with more than one PCB and a lot of interconnection, flex cable is not easy to do in mass production in a small form factor

Just found this mod….awesome stuff.

Could you please elaborate why? I see oshpark offering flex PCBs for a reasonable price and I before I saw your post I assumed that production volume would be significantly cheaper…

I think he meant small factor assembly is difficult and expensive, not the production of flex pcbs.

I can vouch for the wiring being a nightmare. I ordered some 36 AWG wire after seeing this, and had a use for it recently. It seems about as thick as a dog hair. I had trouble with a board mounted switch, so ran a couple 36 AWG wires to patch it up. The fix worked, but, wow, can't imagine doing a lot of these wires like done here.

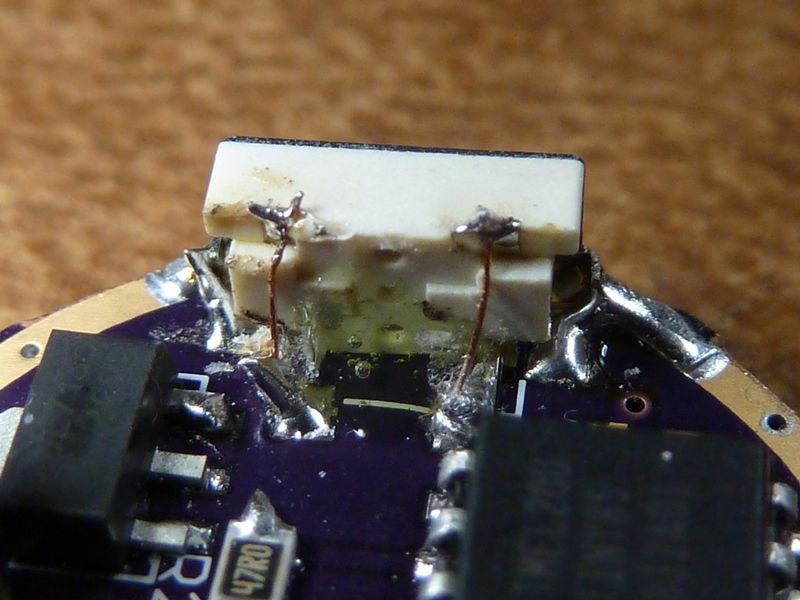

Here's mine:

Dunno, maybe my 36 AWG is thinner than what he used. As you can see, it sure looks messy closeup but the tabs on top were recesses into the plastic, so some of the plastic got melted. To further complicate it, I tested the switch before applying the epoxy and it worked, but after installed in the light, it worked for 5-10 times, then stopped working. Letting it cool down, it would work again another 5-10 times... Strange, but the solder bond probably wasn't made. For switches like this, they need extra bracing, so I use extra solder on the front and epoxy on the baxk - never has one of these beefed up switches fail.

All the wiring in this light was done with 34AWG, which is my preferred size for general use. I also keep a roll of 40AWG for the rare occasion that 34 is too big, but that stuff is extremely difficult to work with.

Dang, I must have mis-read that, I see now you said 34 AWG - I ordered 36 because I thought that's what you used :FACEPALM: . Sux get'n old... ![]()

Ok - I see Remington has 34 AWG, 200C rated, 2 oz., 1011' length - $8.30 on Amazon Prime. Does this sound like the same stuff you are using?

Another Q - the 36 AWG seemed impossible to strip. I assume just touching the iron to it is enough to melt off the coating, same for the 34 AWG?

@tterev3, since we are at the topic, would you mind telling us a bit more about your tools and work environment?