Hey there,

so i am starting this thread because i was photo documenting my emitter swap of the sst40's out of my Astrolux EA01s while putting the SFT40 emitters in. i have many more photos but at this point, this thread is not about the success i have had swapping the emitters and showing that to you.

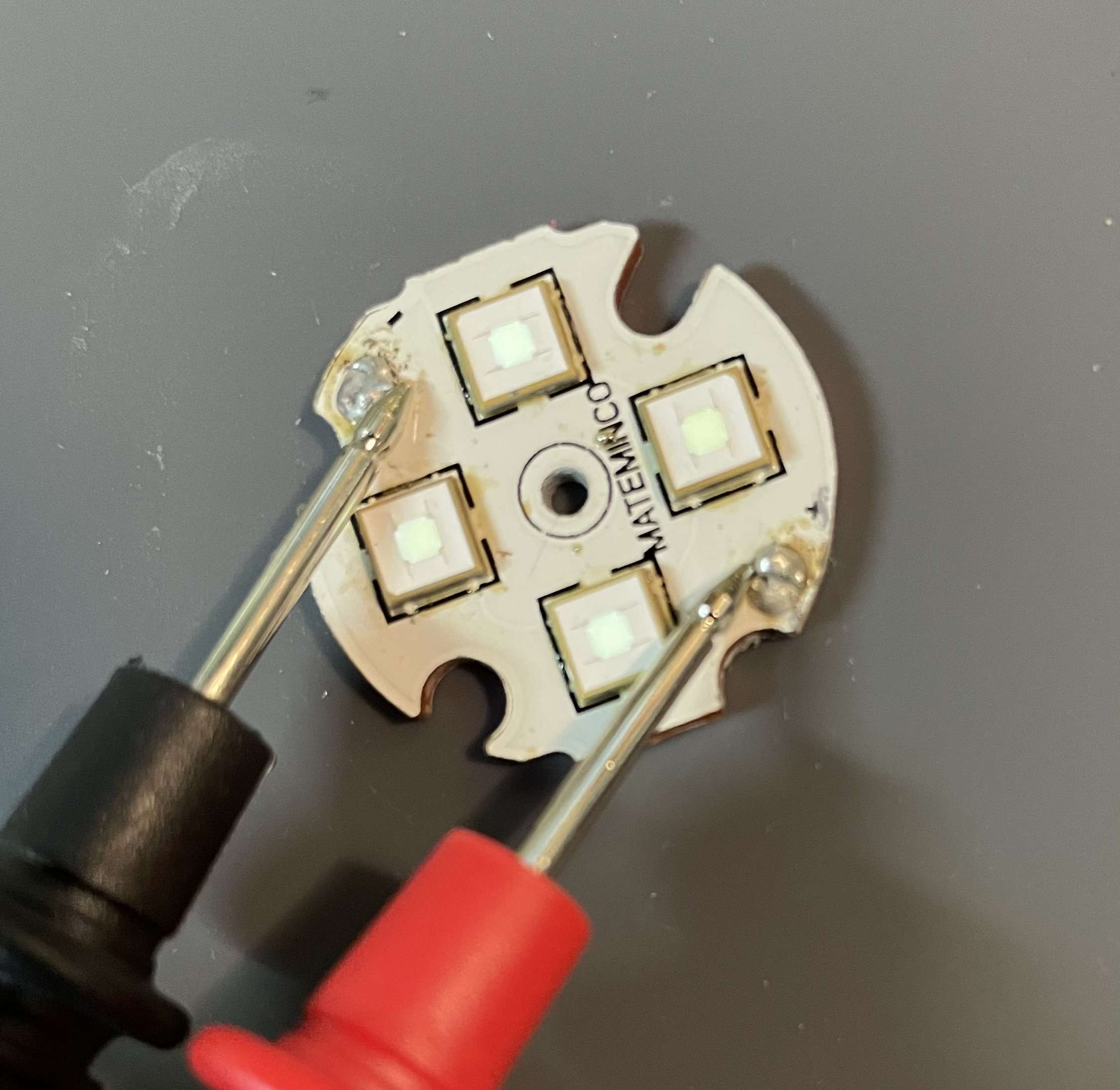

After flowing the SFT40 onto the stock EA01s mcpcb (pic shows them on the board) , and resoldering the mcpcb back into the light, the "failure" happened.

Before reinstalling the reflector, centering rings, lense and bezel i screwed the head back onto the battery tube, as i always do, to make sure everything is working OK (even tho i tested the emitters with the DMM to make sure i flowed them in the right orientation).

Once i tightened down the head to the battery tube, the light goes into, what i can only describe, Direct Drive Mode! the switch does not "work" at all, meaning i cannot use the switch to dim the light, turn the light off, or even do a reset. the light is just ON, full blast, and there is no stopping it until i unscrew the head or tailcap to turn it off..

I can attach more pictures, but does anyone have any idea what i may have EFFED up?? I removed an dresoldered the mcpcb about 3 more times and it does it every time. I kindve split the negative driver-to-mcpcb wire coating, so i used heat shrink to cover the negative wire better to make sure it wasnt contacting the flashlight body or the mcpcb. it didnt help. I sanded down the edges of the mcpcb as it was very tight fitting and i was worried maybe i did not center it 100% OK and it was touching the edges o fthe head of the light and making contact and thus bypassing the switch (I don't know if that is even something that can happen).

A couple of notes i think may be significant:

- the negative wire was VERY difficult to originally desolder. it was "tight" or maybe "hard" would best describe it.. i had to really work at removing it from the mcpcb the first time i removed it. hence why i split the coating a little and had to heat shrink it..

- the switch wires are exposed through a little whole drilled into the shelf, and they are VERY close to making contact with the mcpcb when it is intsalled. this is another reason i sanded down the whole edge of the mcpcb, to make it smaller (maybe 1-2mm total) and ensure it was not contacting the switch wires / solder points. it does Not look like they are contacting each other.

- I checked the VF of the sst40 and the sft40 on the data sheets, and they look to be exactly the same. i didnt know if maybe that could have something to do with it..

- does one of those SFT40's look a little duller than the other 3? i thought it did, and i put the mcpcb back onto the hotplate and removed that one, and added more solder paste and reinstalled, making sure to get the extra out by tapping it but also make sure it still sprung back to its place. after all of that, it still seemed a little less bright. I don't know if that matters to this situation, but i did notice it.

I'm at a loss. if i cannot figure it out or if there is no clear answer, i am going to reinstall the SSt40's and if that doesnt work i going to remove the driver, which im sure at that point i will ruin it. lol. oh boy.. brand new light too, this is what i get! thanks in advance anyone who can help!