Lovely discussion here! ahha

My thoughts put relatively simply are.

1) Reflector setup is important - In a throw orientated reflector (Most reflectors are of this type, simple true parabolics) you need the emitter to be sitting as close to the focal point of the reflector as best as possible to optimise throw. This applies in all dimensions. Any light source outside of the focal Point is going to be putting light outside the centerline and therefore will not be concentrating the light onto the same spot, therefore making the hotspot wider, instead of brighter.

1a) SO if you place the emitter too high or too low in the reflector, you are reducing throw. (this is how focusing heads work, shifting the led in and out of the focal point along the axis of the reflector. This is the main flaw with most budget reflectors, not getting the emitter height right with emitter swaps. This can be fixed by the manufcturer, or the DIYer.

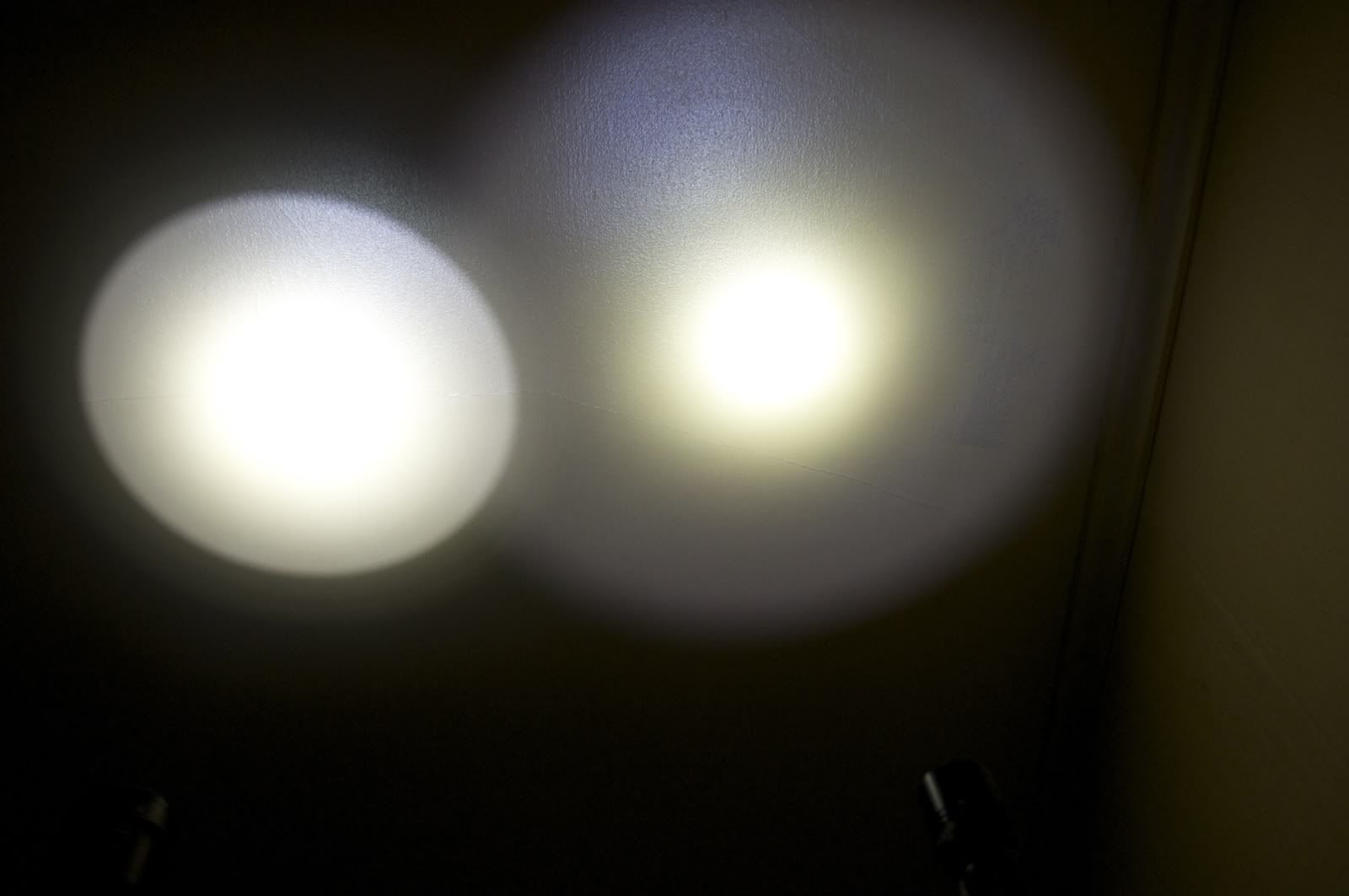

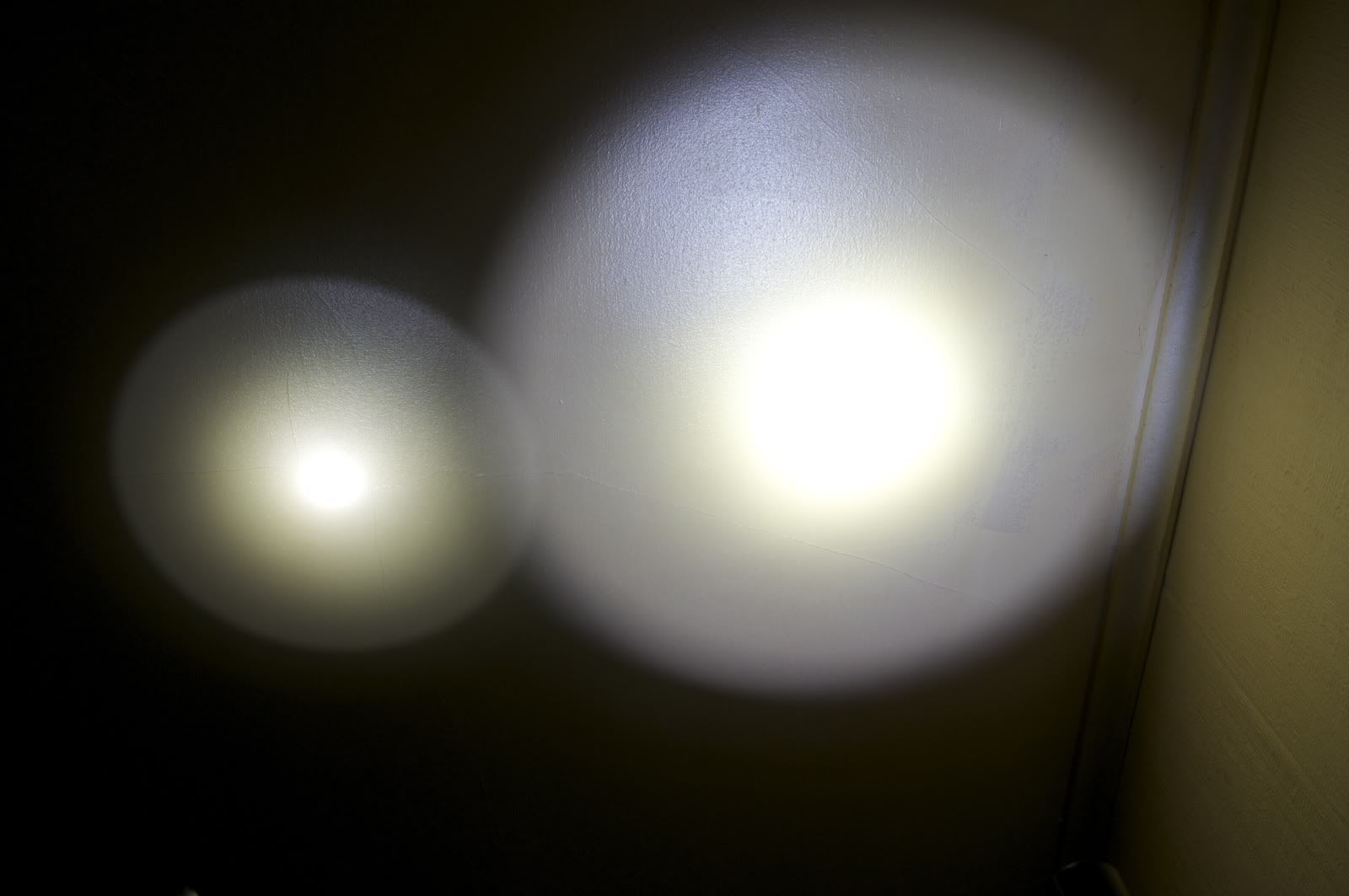

1b) The same theory applies laterally. . The ideal focal point is just a point size. If you place an emitter to the side, the light will project off the axis of the reflector. So lets now imagine the situation with a larger emitter. The center of the emitter is in the middle of the focal point, and projects light down the centerline axis. The edge of the emitter is not in centerline so it will have its light projected off centerline. How far you go off centerline increases the amount of light that is emitted off centerline. So a small emitter will have less light projected to the sides, while a wide big LED will be projecting light light both left and right farther from centerline. This is visually seen as a larger "hotspot"

2) The brightness of a point in the projected light is dependent on the corresponding point intensity of the light source. What I mean is, the brightness of the center of the hotspot, is dependent on the brightness of the emitter in the middle of the emitter. The XR-E has more light output per unit area of emitting surface (surface intensity) is higher. This means that the light reflected from the led will be brighter. The XM-L has a lower brightness emission per unit area of emitting surface, so the brightness of the hotspot will be lower (less "throw") but as discussed in 1B, the hotspot will be much wider.

3) The main problem for throw is therefore focusing the light onto centerline. As described in 1A and 1B, the goal is to place the light source as close to the focal point as possible. How to achieve this?

3a) Brighter light source - were talking Surface Intensity here, not overall light output. The XR-E is the winner over the XM-L for this.

3b) Use a smaller light source - this will reduce the amount of light projecting off axis. (this is why HIDs throw so well, its just a tiny 1mm line arc of light, not a 3x3mm area of light source.

3c) Use a bigger reflector - so that proportionately the same XM-L will be smaller relative to the reflector, and therefore proportionately not as far from the focal point of the reflector.