Crap - I gotta get this T20 mod done!

I just finished a C8 mod: XM-L2 T6 0D/SinkPAD, Nanjg 3.85A. Best #'s after doing the solder flux wick (ooops!) mod to the tailcap spring (picked up 60 lumens btw...), got 1230 @start, 1200 @30 secs on a fresh Panasonic PD. This is only 30 lumens less than a C8 XM-L2 U2 1C/SinkPAD on the same battery, same fresh state, same driver, etc. The T6 0D is clearly a bluer beam pattern though, but I've seen worse XML T6's.

Update 03/20: T20 mod Done! Upgrades: Nanjg 3.85A, 2 copper discs soldered in the pill, XP-G2/SinkPAD, sanded down to fit tight, added solder wick to both springs, replaced switch and rubber boot (blue GIT).

Before mods, stock: fresh Pana B unpro, 3.7A measured, lumens: 731 @start, 615 @30 secs, throw: 34 kcd

After mods, fresh Samsung INR 1500, 3.89A measured, lumens: 670 @start, 646 @30 secs, throw: 75 kcd

Just not sure of XP-G2's bin/tint, but not bad results. In theory, maybe would get 150 kcd dedomed, but I'm still working on a successful dedoming...

Here's some photos of the build:

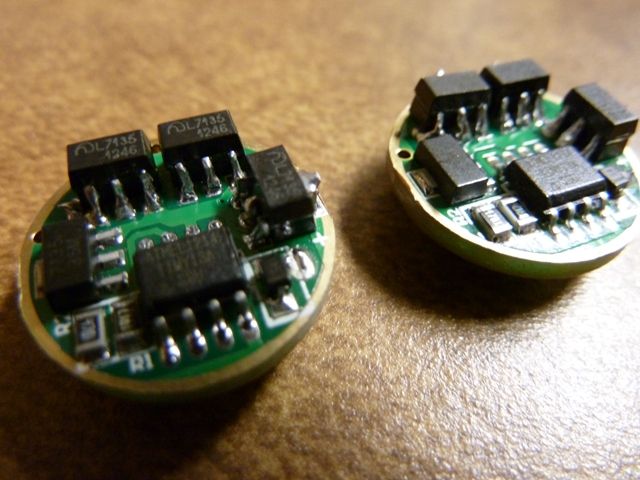

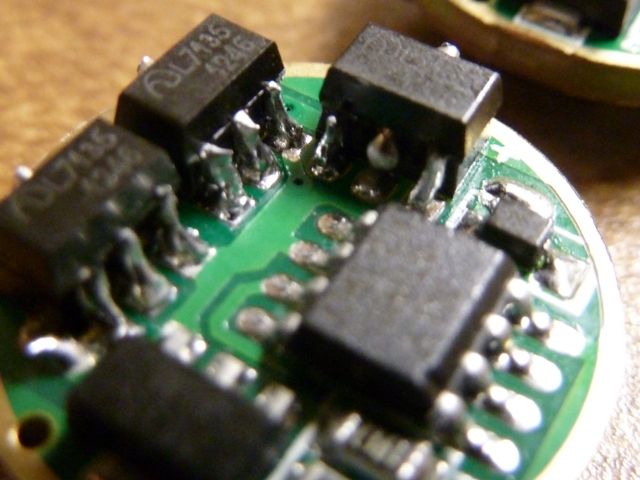

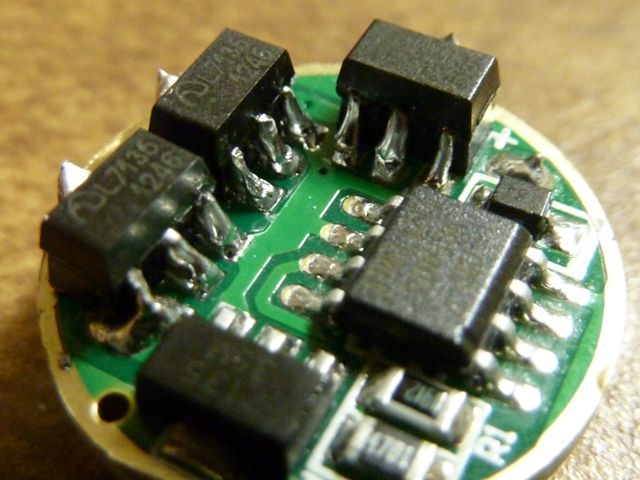

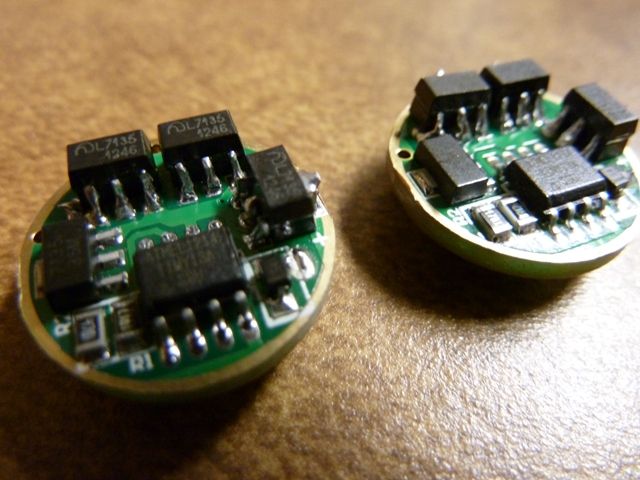

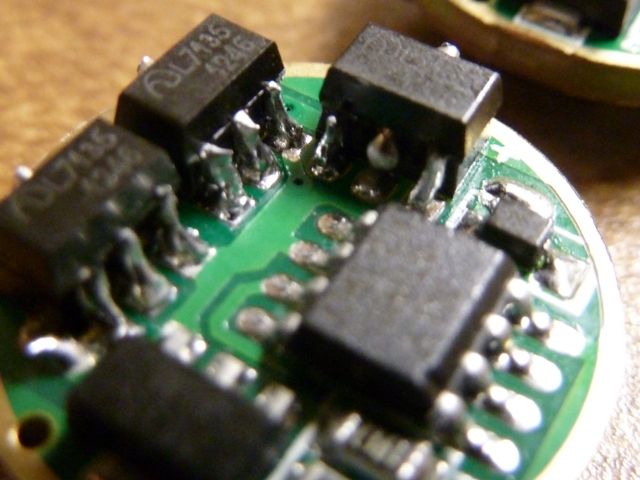

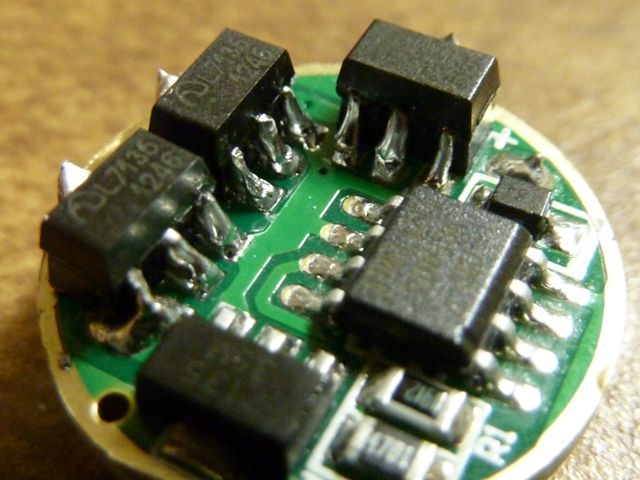

Did two 3.85A Nanjg drivers together, one a C8, other the T20:

On the left is the T20 pill orginal pill, on the right is a C8 pill all polished up:

The T20 pill prep'ed and the SinkPAD all prep'ed and sanded down. For the contact surfaces, I sand starting at 220 or 400, then go all the way to 2500 grit to get them perfectly polished for a smooth contact with thermal grease:

There are 2 copper discs in there, soldered in using solder paste and a torch:

Assembled, tested. LED wires are 22 gauge, silver tinned, teflon coated.

djozz - really liked your picture of this view so stole your idea and did the same shot! It is impressive showing people this direct look at the emitter and SinkPAD.

). At those high amps, I've found the Pana PD 2900 is excellent to get full amps for 3.85A with XM-L2/SinkPAD combos, and the Samsung INR 1500 I got from FT is actually a little better.

). At those high amps, I've found the Pana PD 2900 is excellent to get full amps for 3.85A with XM-L2/SinkPAD combos, and the Samsung INR 1500 I got from FT is actually a little better.

.

.