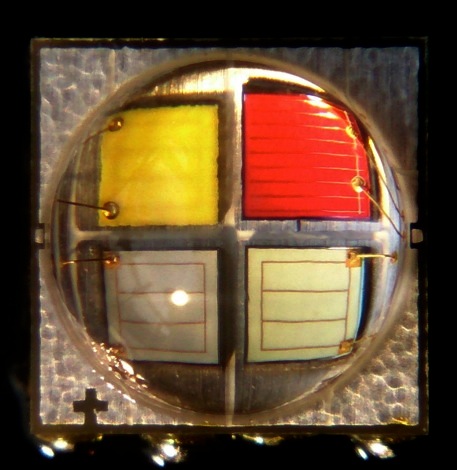

The XM-L colour has been around for about a year now, and I wanted to know the limits of the led since then. But because there was just one flashlight driver around (thanks to intl-outdoor that had one developed) operating at 700mA per die, any performance over 700mA would be irrelevant to most people making a flashlight with it. On top of that, I was mostly interested in the performance on copper, and there's no copper board for it.

EDIT: rollinstone157 pointed out below that there Is an aluminium Sinkpad for the XM-Lcolour.

Recently a few people have made their own rgbw drivers, and Dr. Jones has made a great one available, with all sorts of wild options (like battery capacity measurement  ) but also it has current regulation with common 7135 chips, 2 per die (700mA) but stackable for more :-)

) but also it has current regulation with common 7135 chips, 2 per die (700mA) but stackable for more :-)

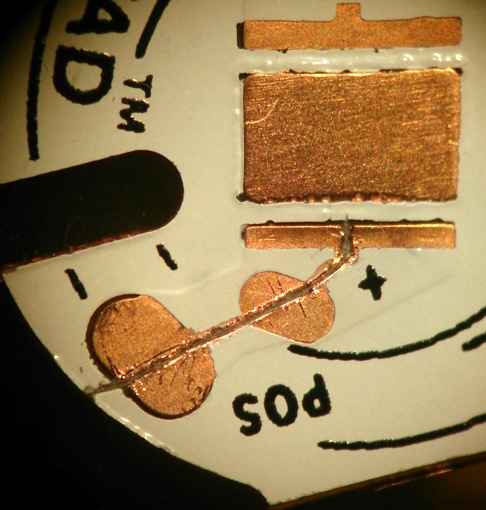

This has triggered me to do these tests after all. A problem was the lack of a copper board, so I had to customise an existing one. The best option was the BLF-developed 16mm Sinkpad because of the wide traces, it should be possible to split them up like this:

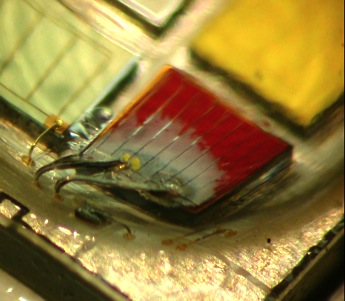

I put a new blade in my scalpel and set off, trying to cut the traces without cutting all the way through the dielectric layer. I must say it was not easy, I did cut too deep at various places, exposing the copper core, and made various shorts to the core of the board that I had to repair by carefully scraping off copper bits, but I got it done:

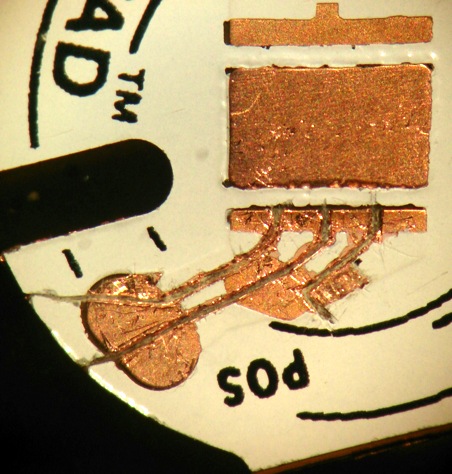

I thought it would save some later trouble with soldering if I filled the grooves with ArcticAluminaAdhesive, so that is what I did:

Ready for the reflow! Added small dots of solder paste on the right places, and checked one more time for continuities with my multimeter: Ai! the third track was shorted to the core of the board  . So I had to scrape away the AA-adhesive out of the grooves, caused another short in the second track with that, and managed wipe loads of solder paste (wish I had checked before adding the paste) into the grooves *sigh*. An hour or more careful cleaning and scraping later, it was clean again, and every track without shorts. I did not dare to do the AAadhesive fill again but went straight on to melt some solder paste on the right spots, using the heat-block:

. So I had to scrape away the AA-adhesive out of the grooves, caused another short in the second track with that, and managed wipe loads of solder paste (wish I had checked before adding the paste) into the grooves *sigh*. An hour or more careful cleaning and scraping later, it was clean again, and every track without shorts. I did not dare to do the AAadhesive fill again but went straight on to melt some solder paste on the right spots, using the heat-block:

That went well at least :-)

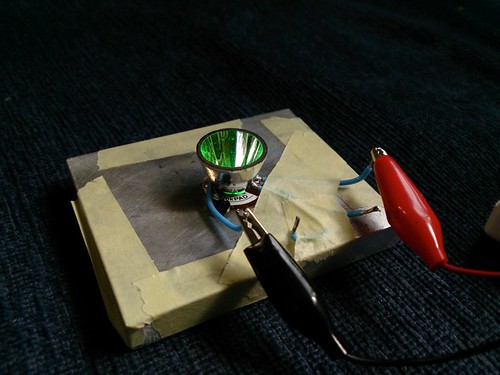

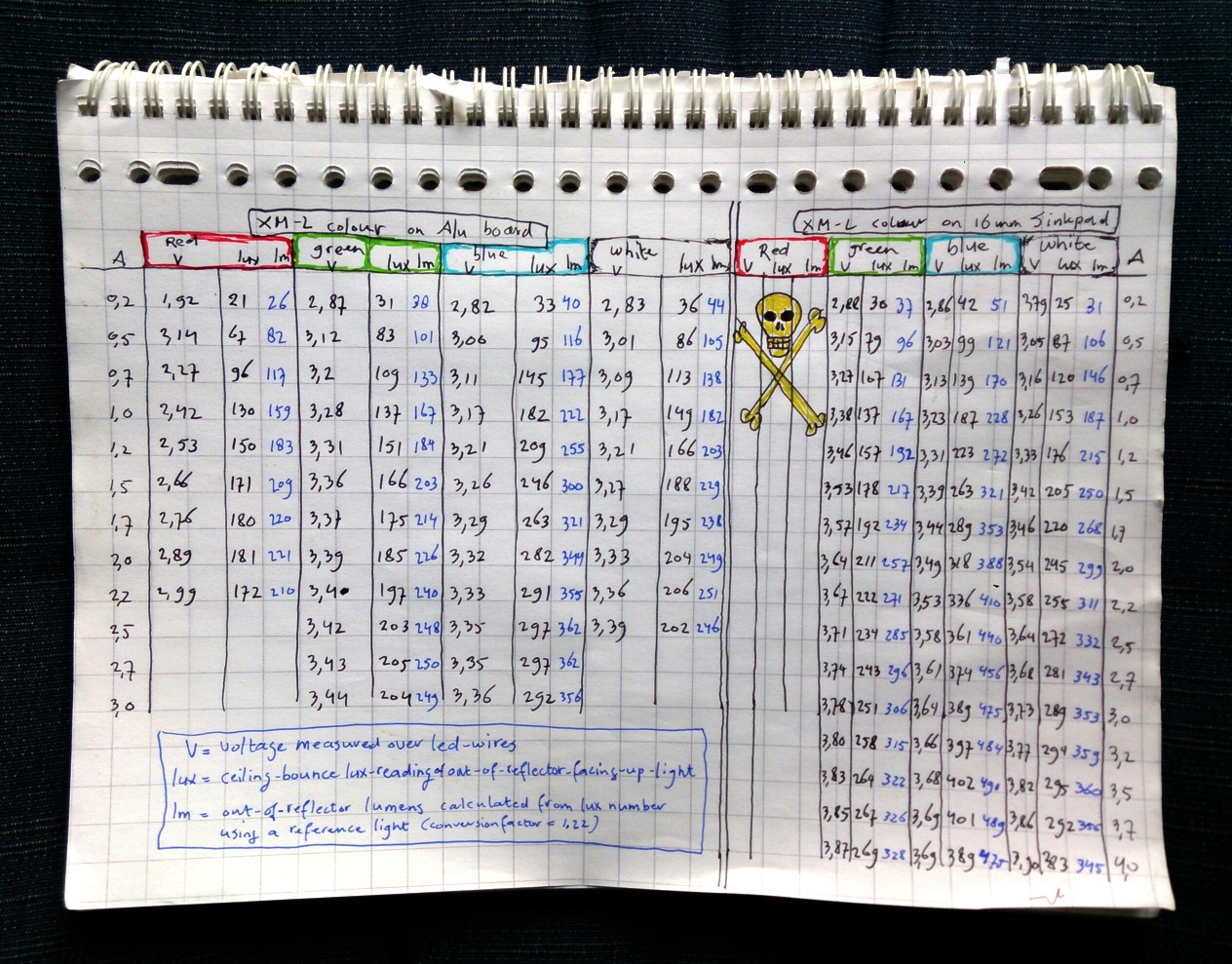

now I first did an output test on the four separate dies on the 16mm aluminium board (from Intl-outdoor) that the XM-Lcolour led came on, so that the results on a copper board could be compared to a traditional aluminium board with dielectric layer (results later in this post). I had an old plastic XR-E-reflector that I filed thinner at the base to get enough clearance for the solder joints on both boards, I used it for the ceiling bounce tests :

It does not give a pretty beam but my lux-meter did not complain about that ;-) Results of the aluminium board tests are later in this post.

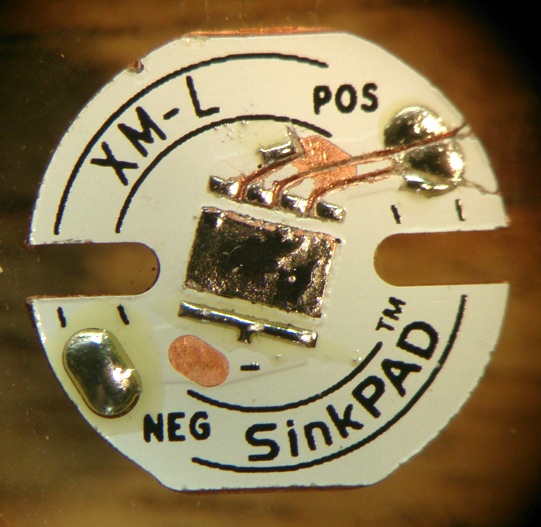

After the test on the original board the led was reflowed on the customised Sinkpad:

It was not until this point that I noticed something seriously wrong with the red die. It worked fine in the aluminium board test, so I must have done something wrong with the wires after that test, i will never know, but testing with a led-tester indeed proved that this die was completely dead. A detail for the disaster tourists among us:

I had plans for this led, on the copper board, for a nice mod with the DrJones RGBW-driver, but it was not meant to happen apparently :-(

At least I did not have to be carefull with the three remaining dies in the copper board test  . So, with one wire less to solder, the led was entering the second test-round, on copper:

. So, with one wire less to solder, the led was entering the second test-round, on copper:

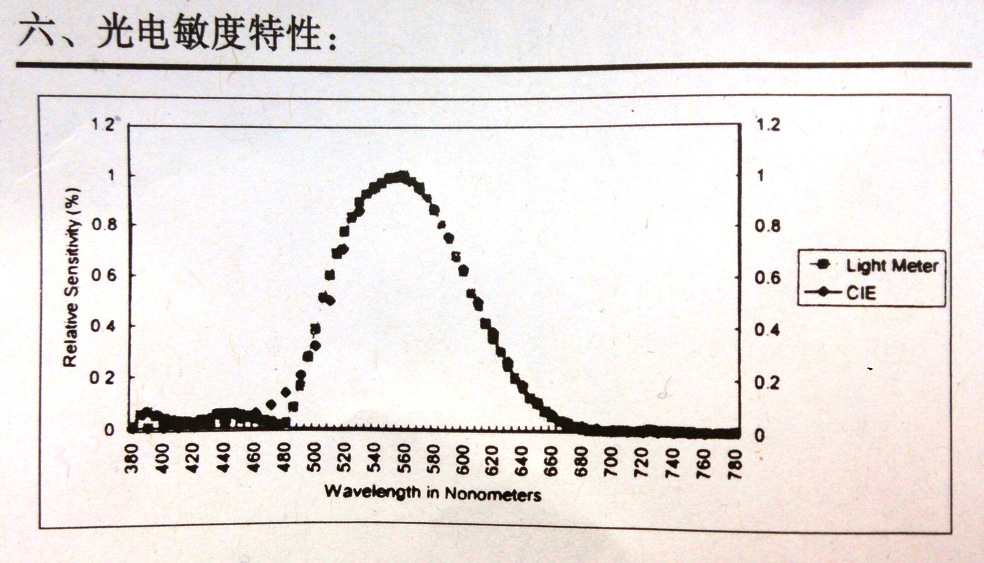

Before going to the results, there is something to explain about the cheap luxmeters that most of us (including me) use. One thing that an expensive calibrated luxmeter does well, is following the 'human eye respons curve' that is at the base of the definition of the lux. My luxmeter does give very consistent readings over time that are not influenced by battery level, it gives a nice lineair response to increasing light levels, I am very happy with that, but when measuring colour leds, you should not trust the actual lux-values too much, especially when the colour is near the edge of the curve (in these tests: the red and especially the blue die). And it proved impossible for me to find a graph that gives a wavelenghth response curve for my luxmenter compared to the human eye response. I have a second cheap luxmeter (a Ceto ct-1330B) that comes with a leaflet with this great chinese graph (CIE=the human response curve), that is all I have about these luxmeters:

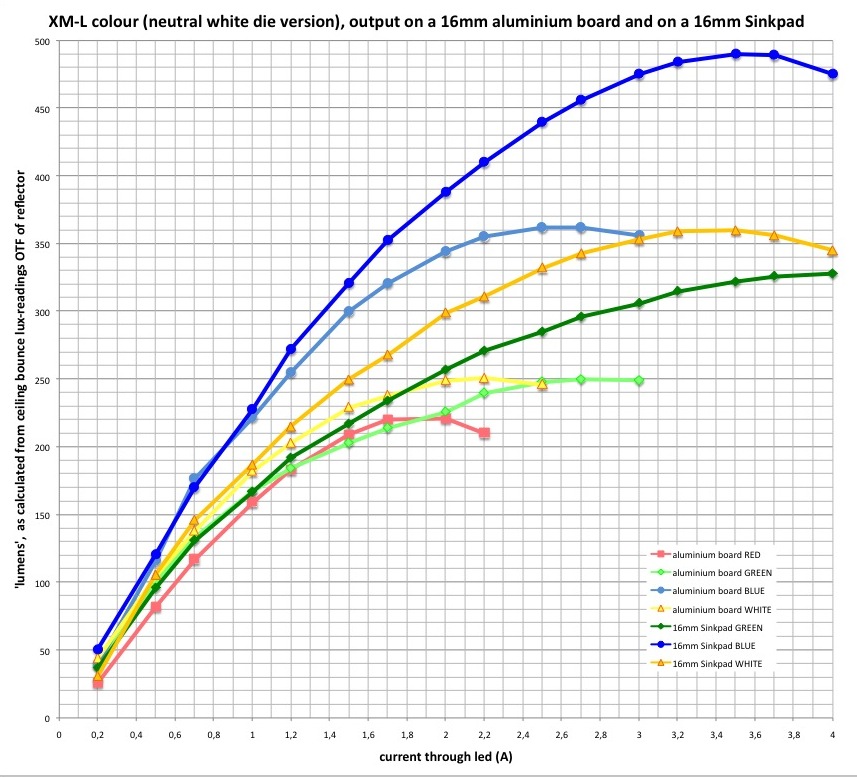

So now that you know (exept for the white die, that should be ok) not to trust the absolute lumen numbers for this test much (the relative numbers within one colour are completely comparable by the way), here are the results:

I think the lumen-numbers are the most interesting, so I put them in a graph together:

So for me there's two conclusions from these tests:

-on the original board the recommended max current of 1000mA/die for this led is a bit low for us flasholholics, if I would build a flashlight with this test in mind, I would use 1.5A per die (that is already 6A battery draw when all dies are switched on!)

-the copper board really helps, also with the XM-L colour! In a flashlight build I would increase the current to 2A :-) , giving 30% more output compared to a aluminium board. I did not do measurements with more than one die switched on at the same time, but in that scenario the advantage of the copper board over the aluminium one will only increase.

I think that the market (at least the flashlight market) is too small for a dedicated copper board for the XM-L colour, so whoever wants this led on copper will have to do some DIY, sadly :-( . Edit: there is an aluminium Sinkpad for the xmlrgbw that should perform just as well as a copper one. And when the funds allow it again I will buy a fresh XM-L colour led for the mod I want to do..

thanks for reading!