Well I’ve been having fun with graphs again.

To check whether my thoughts in my last post where correct I did another test. This time eliminating the battery pack and cable entirely, plugging the two packs across a reinforced harness and directly into the light. I also rigged up my hefty power meter to measure current.

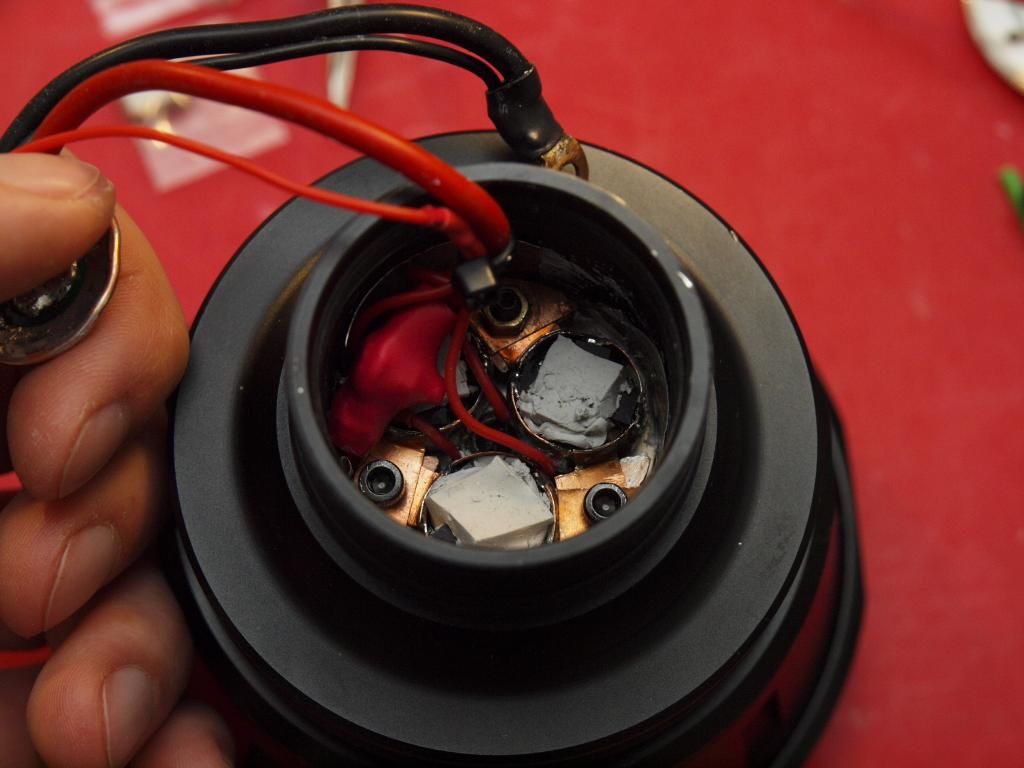

Here’s my test setup

And the balance board reinforcements I needed to make to reduce resistance losses to a minimum

—

This way (by eliminating the resistance loses across the spiral cable and relays in the pack) I am verifiably gaining 0.6v in voltage overhead compared to the fully assembled light. That should eliminate any concerns that the voltage is dropping too low and causing the sag in output/regulation.

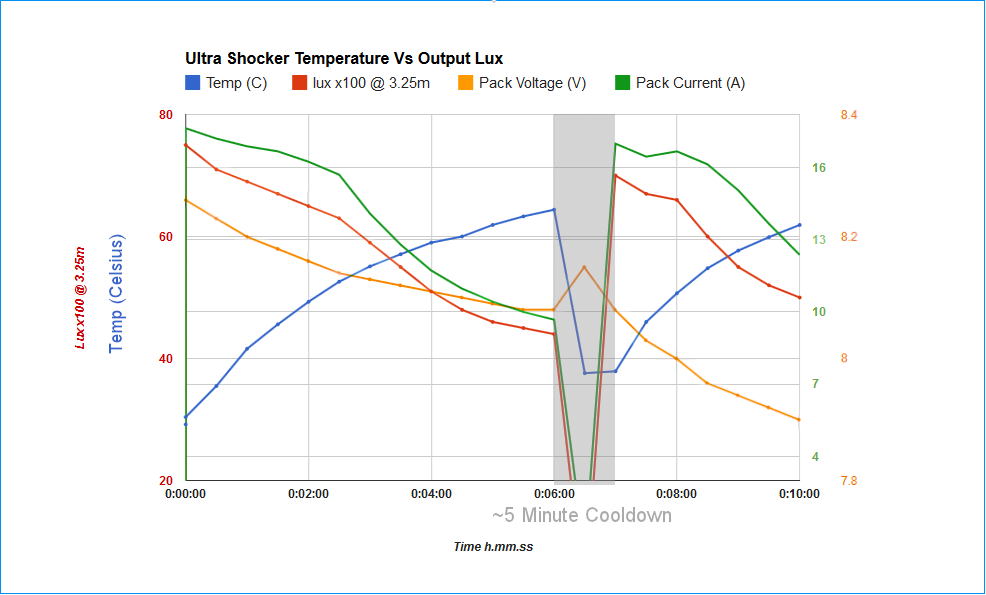

The test was carried out in two parts.

1. I ran the light on high from cold taking Battery Pack voltage, Battery Current, Lux, and Heatsink Temperature readings every 30 seconds.

2. After 6mins I turned the light off and let it cool down for around 5 mins.

3. Then I ran the light again for another 3 minutes taking all the measurements again.

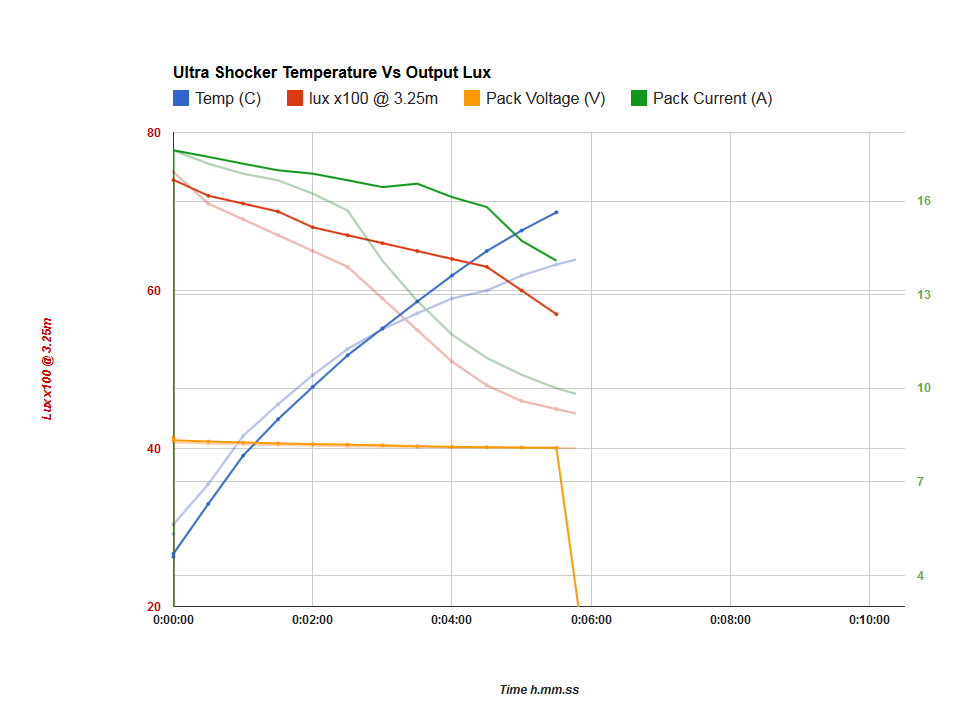

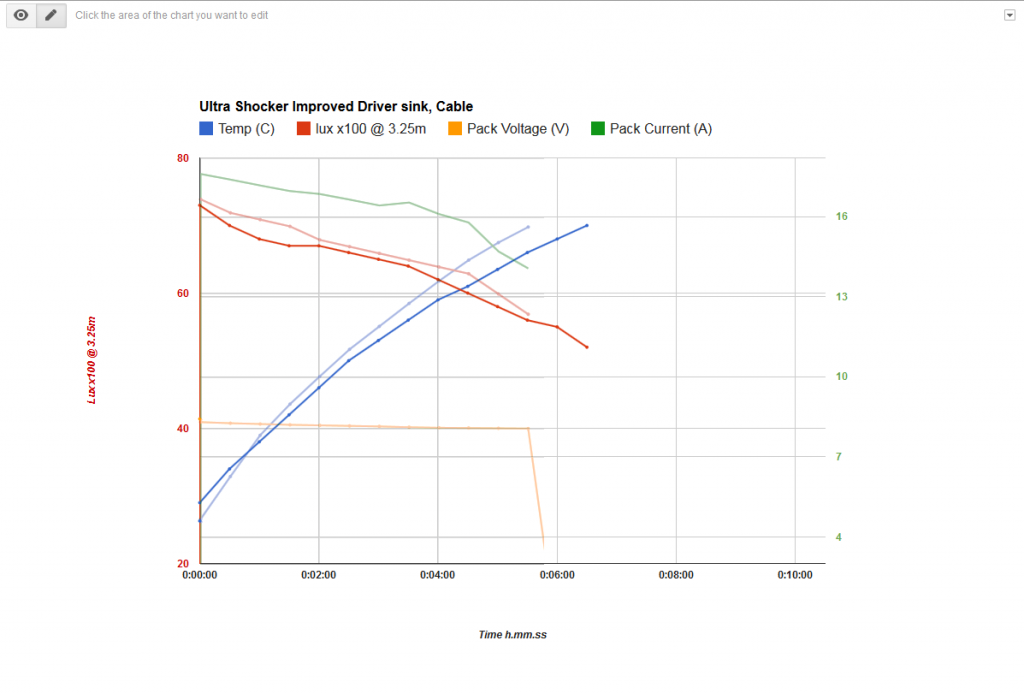

So here’s the graph.

It’s quite interesting, and I think it verifies quite nicely my thoughts that driver heat is the primary cause of the drastic output drop overall, but especially after about the 2minute mark.

In fact with the higher voltage reaching the driver this time, I see a less stable regulation phase initially that drops more quickly and more steadily than with the fully assembled light. Last time between 1:00 and 1:30 I saw a flat spot in output (indicates decent regulation), this time it’s all downhill from the start.

After the 2 minute mark again output takes a nose dive. And this time it took only 4 minutes before the output had collapsed to 50klux while on the fully assembled light it took a minute longer to drop to the same level.

The voltage gradually drops as expected during the test but the crucial bit regarding this aspect of the situation happens after the cooldown period.

At the 6minute mark battery voltage under load was 8.08v, during the cool-off period with the light off it recovers up to 8.15v however crucially upon turning the light back on for the next part of the test it is bang on again at 8.08v.

As a result the output and current readings taken right after the light is turned back on can be compared directly to the ones taken before the cooloff period. With battery voltage being bang on identical between these two points the only variable to blame for the massive difference in output/current draw has to be heat. Aha!

You can also see that with the lower battery voltage at this point, the driver actually has more of a chance to try and regulate current and there is even an increase in driver current and output a minute after the restart. Unfortunately it doesn’t last long before the sharp drop once again kicks in.

Finally, having the current readings and seeing them track pretty neatly with the output measurements rules out thermal deterioration at the leds being the primary cause of output sag.

—

My conclusion is that the driver assembly is choking on it’s own heat and can’t shift it away quick enough, as a result it drops output prematurely.

It’s probably just keeping up while the temperature of the pill is below 50degress, but once it’s environment has reached that temperature and beyond it’s a losing battle and things start getting really toasty quickly.

I will try to do something to maximize thermal contact between the aluminium driver assembly and the walls of the pill. Maybe by stuffing some aluminium foil in there are and applying a bit of thermal grease. In any case I’ll redo this test to see if it has made any noticeable difference at all, suspect it won’t do all that much but it’s worth a try.

There’s just too much heat involved here, liquid nitrogen might be the only solution ![]()

Next one of these will have a copper slug sinking those 7135s! Or a bunch of ventilation holes and a blower fan keeping things in check :bigsmile:

—

If anyone has any thoughts on this dataset it’d be appreciated, hopefully I’m interpreting the data correctly and not barking up the wrong tree here.

Cheers