That's a whole lot of shavings you found inside that 3.25" round stock.

Looks like it's going to be a very sweet, but serious light. :)

That's a whole lot of shavings you found inside that 3.25" round stock.

Looks like it's going to be a very sweet, but serious light. :)

I can’t wait to see a beamshot from this thing. 40watts+ from an XP-L size in a Courui reflector… Wow

Great work. Look forward to reading about the end result.

subscribed!

i wish i had a lathe! ![]()

i learned to work with them - but have none to use if i have an idea.

so it takes looong to build something from old parts than just making what i need….

Nice. I feel for you when you mentioned boring a large hunk of aluminium out taking all day. Even turning the outside would be a marathon effort. Thanks for the update.

Nice!

Do you have a closeup of the driver? What did you change to make it run at 4s? What firmware are you using?

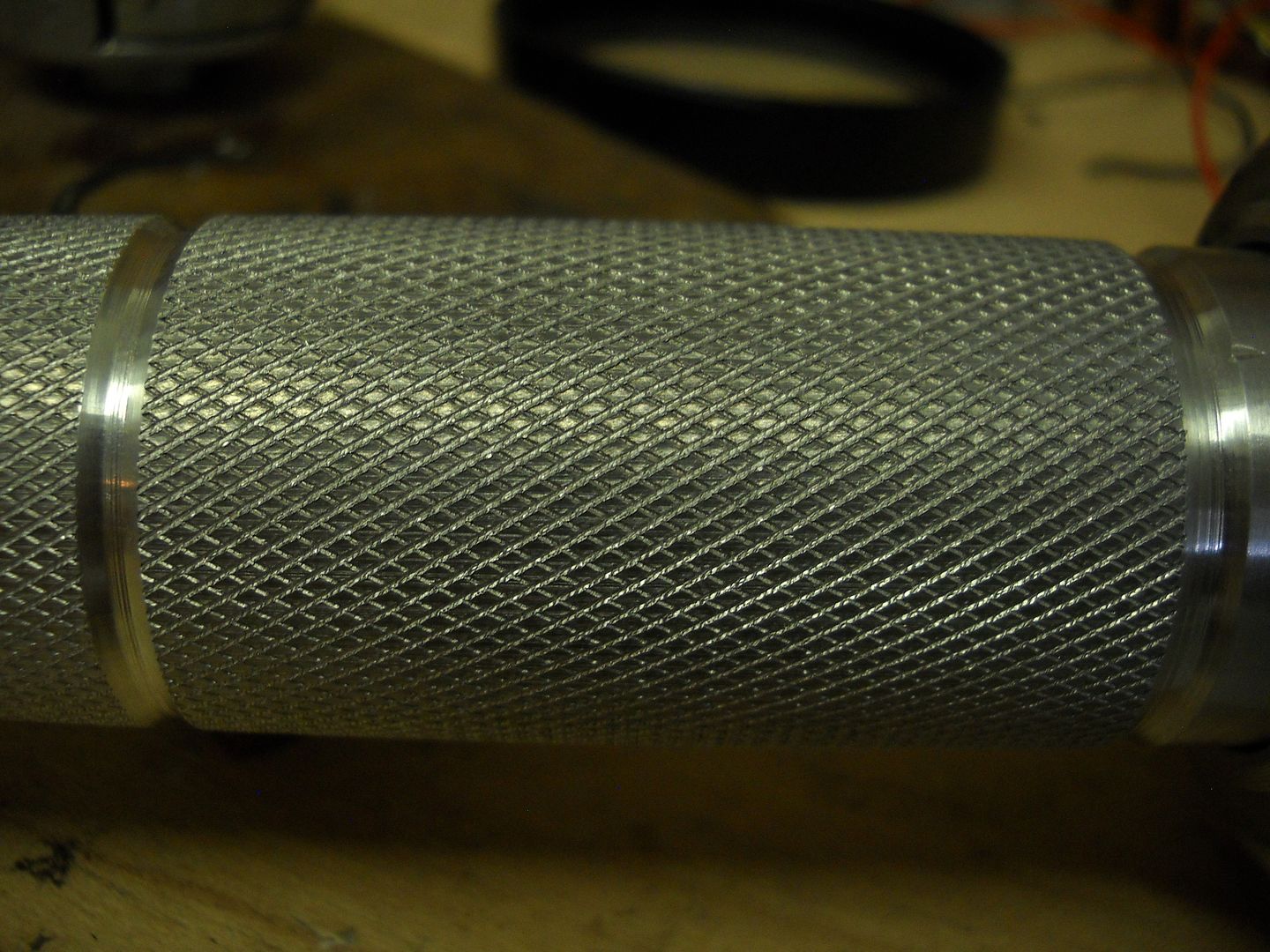

Great to see another of your creations! I love knurling. Just love it.

Nice work! The knurling looks spectacular and I can’t wait to see the final product.

You might consider running 26650 LiFePO4 cells to reduce the power slightly and have less voltage sag. I did that with direct drive on 3 XHP-70’s with terrific results, over 15,000 lumens.

Also looking forward to seeing what this XHP-35 does at those levels. I have components on the way to use with an LD-2 for a build I’m doing with one of these emitters, should be here today actually. I was planning 2A but now I might go a little higher… ![]()

Thanks for sharing, and for the words on Josiah. ![]()

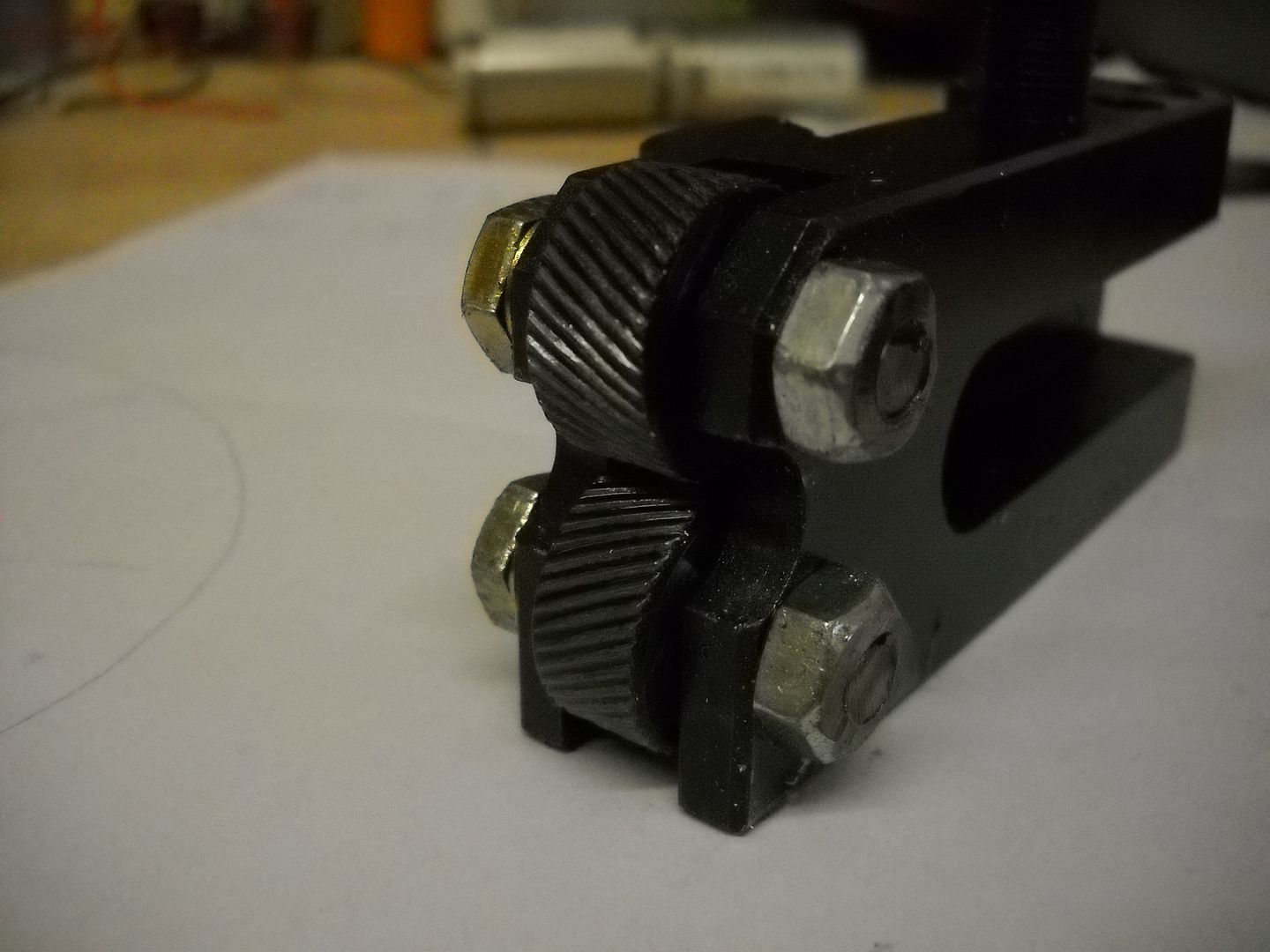

Typically you center the part between the two and run an "X" pattern on the part, but I have found I get better results ( especially on a long part) by running one wheel and then the other.

A close up of the result.

17mm & 20/26/27mm single-sided DD/FET driver release: A17DD-SO8 / A20DD-SO8 / etc

Nice work. The knurling looks fantastic.

Thanks for showing how the knurling is made. The tool and the knurling you created are just too  . Sure seems like it would take a lot of pressure and consistency to get it right.

. Sure seems like it would take a lot of pressure and consistency to get it right.

WOW!! Fantastic work! Thank you for sharing VOB. I dig the Grizzly

Excellent work really and it was interesting to read how knurling is achieved too. I wondered how it would be done in simple manner. I’ve never used a lathe but I can see how useful it can be for such work.

Another knurly beauty from VOB’s workshop. Looking forward to more lathe, and tooling info… very interesting.

Coming along nicely!

Quite a large update added to the OP. Including LUM 5-90 and more on the head.

Gr8 build man! Your reign has started!

looking good! ![]()

I like the reverse tapered head. I dont think Ive seen that done in a light of that size before.