Cutter are usually fairly forthright with their sales, so I’d give them the benefit of the doubt unless proven otherwise. For reference the Tpad DTP stars look like so: 14mm 20mm

Say… would you be interested in parting ways with 1 or 2 of those 4000k 219Cs at all?

They did the same thing with an XP-G2 here: http://www.cutter.com.au/proddetail.php?prod=cut1954. Shows the Noctigon, but says "20mm Round Shaped Metal Core PCB", which means it's a MCPCB, that's it. The link to the MCPCB is broken as well. It's not looking good.

It's a shame because they got them bare obviously because MRsDNF bought them that way, just no way to buy them on the site.

I left a query on their site about it - no response yet.

Well it’s Sunday night here and the first of the posts on the issue by ImA4Wheelr was on Friday night (Melbourne time) so we shall see soon. It’ll be Monday midnight in a minute. TBH, I’d prefer them bare as Noctigons don’t come in anything smaller than 16mm.

Just to clear things up I bought six leds and six stars, both separately. I never ordered anything by part number.

There wouldn’t be continuity on any of the solder pads, as those are isolated by the masking… by necessity of course.

Try placing your probe right at the base of the emitter where it solders to the star, usually there’s a bit of a shine right there where the solder is. Or you can simply press the probe through the mask onto the trace coming away from the thermal pad. (scratch it slightly, in other words, to get contact through the masking to the trace underneath.)

I’d put it on a hot plate and pull the emitter, easy enough then to find out if it’s DTP or not.

Look at the information from SinkPAD on their DTP Al boards compared to the DTP Cu boards, the copper ones are much more efficient. The Al ones are fine if you’re not pushing to max levels, but the copper ones can’t be beat up on the top end.

Guys

The Alum boards are not DTP, we have Tpad due in 3 weeks in XP footprint but these are not and were shipped by mistake, so we will rectify this, if you order on Noctigan boards, thats what you will get

I am currently in the UK so my answers may be delayed

Cheers

Mark

Hi Mark - thanks for posting!

Just to clarify for me and to be honest, the main thing is the pictures on your website for the 219C product show a LED on a Noctigon - I really didn't expect a Noctigon to come with it for that price - price was too low. I made a mistake in thinking it was a bare LED, not mounted - missed the note it was mounted on a 20mm star.

Still waiting the hear back for Cutter or welight. I trust that he will straighten this matter out, but the lack of response is starting to get me concerned.

The HI versions just have a very thin flat layer of silicon over the die. I’ve wondered if instead of a complete dedome just use a centering disc as a jig to get an even thickness slice and make the cut submerged in an alcohol lubricant bath the make it as clean and smooth as possible.

Out of all the emitter’s I have shaved down, the 219c was the hardest, literally, it need’s a Rockwell hardness number! But after initially shaving the biggest part of the top off I pressed down harder on the washer I was using and shaved almost a perfect surface and a less than paper thin shave off it that came out with just light wet sanding and then a toothpaste polishing! I have tried synthetic Mobil 1 oil to liquid soap as lubricants, it helps out, especially on the second cut or shave! You got to keep the angle of the blade slightly raised towards the rear to act as a scissor action against the washer or guide, and the tighter the I.D. to dome O.D. the better, less pressure pushing on the dome, slow and easy on the cut, let the blade do the work. I’m sure there are other way’s and of course Better way’s, but this works for me, and I do it a lot, so take it for what it’s worth, .0002cents! :bigsmile:

Heading back home tomorrow so will resolve this as soon as I land

Cheers

Mark

That sounds like a very thorough manual, thanks, I will use this method :-)

Picture of the result?

Ah, while I was sleeping a new emitter came out that I almost missed (thanks ImA for the alert)! Thanks djozz for your testing! Might have to order a couple to sit on my workbench for months and months with no use . . . ahem, I mean to mod some lights with.

-Garry

If your hobby time is limited, the choice is: get some emitters and let them sit there or keep the workbench empty and hope for Nichia to come up in the coming months with a 90CRI version after all :-)

(although they claim not to work on that)

Kawiboy emailed some pictures of his shaved XHP70 to me for posting because his computer was not able to post them on BLF, here they are 4 of them :-) :

1:

2:

3:

4:

I know a few people ordered the 4000k from Cutter. If any of you have extras, I’m looking to buy 2-3. If I needed more, I’d just buy from Cutter myself, but for 2 the shipping isn’t quite worth it to me.

Solved by a helpful Aussie

For an X6 triple I think I might do a tint mix with 2 4000k and 1 5000k.

Ola Djozz,

Why do I not see a donuthole? Is that because of the shaved dome or am I missing something here?

Also, is it place in a Fenix TK61?

Schöne Grüße, ![]()

Nico

Attempted acetone dedome of a 4000k 219C, dome became crumbly (not soft at all) after 90 minutes in acetone. Most of the dome came off very easily, leaving a few bits stuck on the die. There is phosphor under the white stuff, which was removed to reveal a gold-plated substrate. The remaining dome was carefully cut away using a razor blade in successive slices, leading to a good looking result.

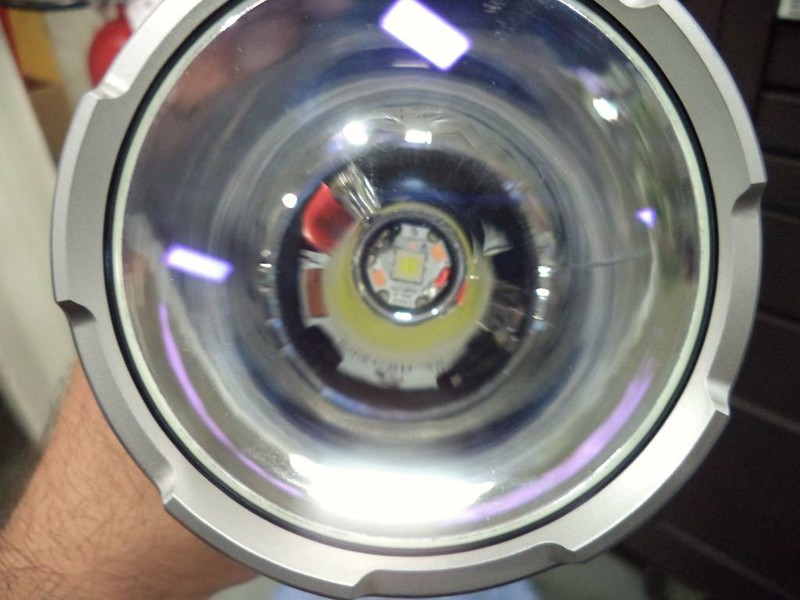

Reflector and beamshot (underexposed to show tint)

Hmm, that slicing may have been a little overzealeous especially near the edges of the die… I wonder what the CRI is now…

Ola Djozz, Why do I not see a donuthole? Is that because of the shaved dome or am I missing something here? Also, is it place in a Fenix TK61? Schöne Grüße,

Nico

Ha Nico, those pictures were from KawiBoy1428, I posted them for him. So I can not answer your questions :-(